Power supply and converter valve thyristor assembly fastening force sensor

A technology of power supply and thyristor, which is applied in the direction of current collectors, electrical components, battery circuit devices, etc., can solve the problems such as the inability to detect the fastening force of thyristor components, achieve real-time detection, reduce dependence, and realize the effect of de-batteryization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

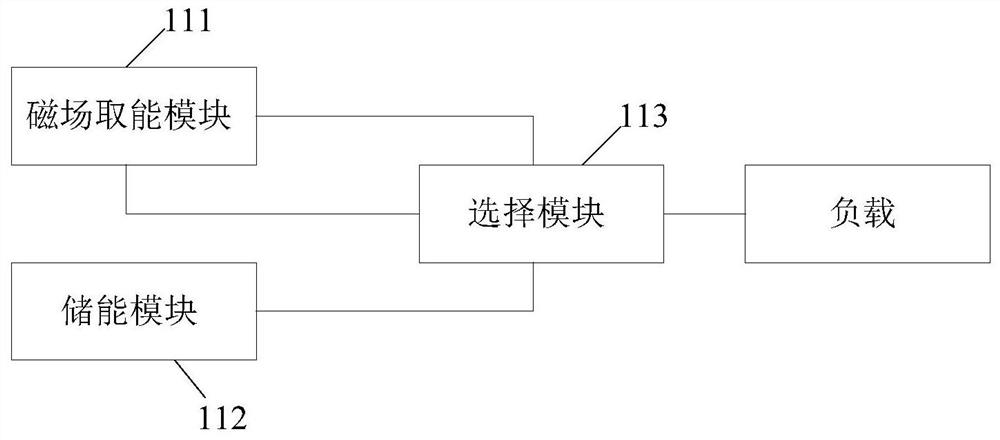

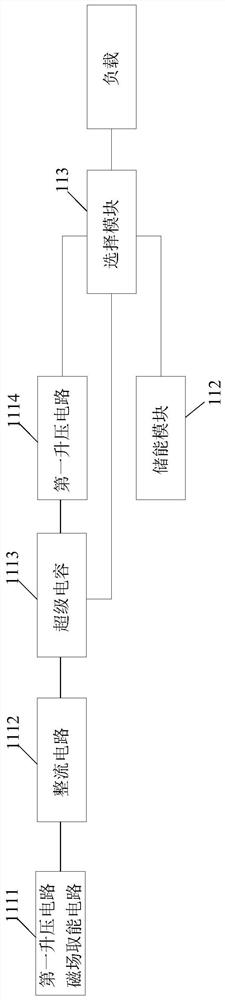

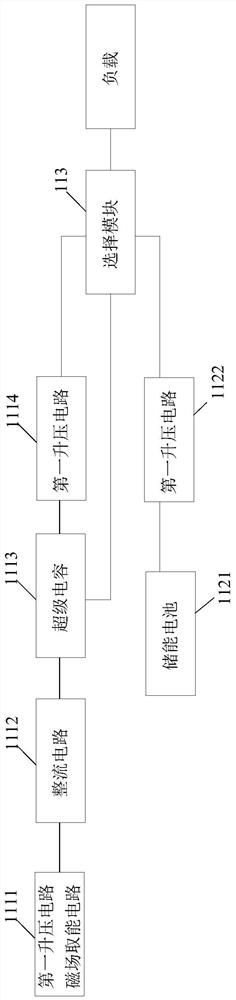

[0030] Embodiments of the present invention provide a power supply 11, such as figure 1 As shown, the magnetic field feed module 111, the energy storage module 112, and the selection module 113.

[0031] like figure 1 As shown, the magnetic field substance module 111 of the embodiment of the present invention, the first end, the second end, and the second end, and the second end, for the second end of the selection module 113, for utilizing the electromagnetic induction principle, to obtain the induced voltage, and will Inductive voltage rectified post-storage.

[0032] Specifically, the magnetic field substance module 111 of the embodiment of the present invention is placed in an alternating magnetic field, which can be stored using a non-invasive coil induced magnetic energy, and converting magnetic energy into electrical energy.

[0033] like figure 1 As shown, the energy storage module 112 of the embodiment of the present invention is connected to the third end

Example Embodiment

[0047] Example 2

[0048] Embodiments of the present invention provide a converter valve thyristor assembly fastening force sensor, such as Figure 4 As shown, the thyristor assembly is composed of a guide bus, a plurality of thyristors, a plurality of heat sinks, and the thyristor and the heat sink are alternately connected in series, and the final current flows from the guide bus discharge, and the thyristor assembly is applied by the top pressure mechanism.

[0049] The fastening force sensor of the embodiment of the present invention includes: a self-adaptive sensor module 1, a pressure sensor 2, and a self-extracting energy sensing module 1 comprises a power supply source 11 of Example 1.

[0050] like Figure 5 As shown, the pressure sensor 2 of the embodiment of the present invention is disposed on the pilot bushing, embedded within the jet pressure mechanism, for sensing the top pressure applied by the top pressure mechanism;

[0051] like Figure 5 As shown, the self-adaptive e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap