Efficient metal reflection type thermal insulation material

A technology of metal reflection and thermal insulation materials, which is applied to ceramic products, other household appliances, household appliances, etc. It can solve the problems of metal materials with general heat insulation performance, poor reflection heat radiation effect, and inability to prevent heat diffusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

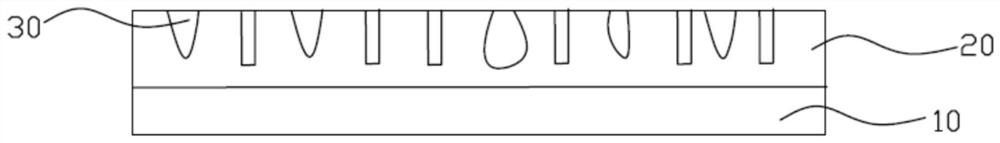

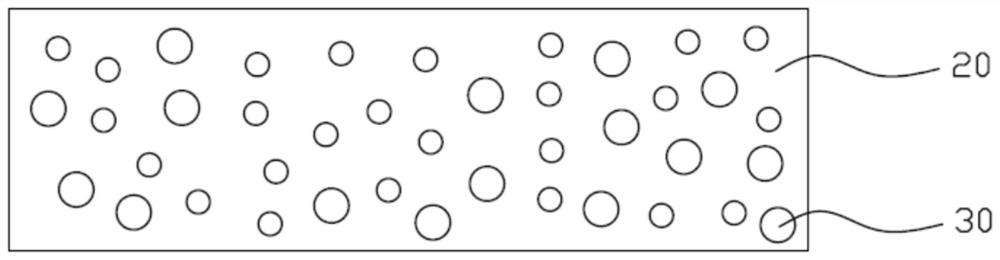

Image

Examples

Embodiment

[0032] Porous SiO 2 Granules are produced by the following steps:

[0033] Perform ion exchange on sodium silicate to obtain the first silicic acid with a pH of 2-3; pass the first silicic acid through an anion exchange resin to obtain a second silicic acid with a pH of 5-6; pass the second silicic acid through cation exchange Resin, to obtain the third silicic acid with a pH of 3-4; add the third silicic acid to the reaction kettle, add KOH solution at the same time, heat at 120°C for 40h, and obtain SiO with a solid content of 45%. 2 solution, the SiO 2 The solution is dried and ground to obtain the porous SiO 2 particles.

[0034] Titanium dioxide is produced through the following steps:

[0035] TiO 2 ·nH 2 The molar ratio of O and KOH is 0.5, add an appropriate amount of water and grind it evenly in a mortar, then sinter in a muffle furnace to 880°C, keep it for 2 hours, and slowly cool to room temperature to obtain the intermediate product K 6 Ti 2 o 7 ;

[0036]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap