Ear strap connection production and processing mechanism based on plane mask production

A technology for processing mechanisms and masks, which is applied in the field of connecting production and processing mechanisms based on ear straps for the production of flat masks, can solve the problems of reduced detection strength, detachment of the mask ear straps, lack of auxiliary inspection of the welding strength of the ear straps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

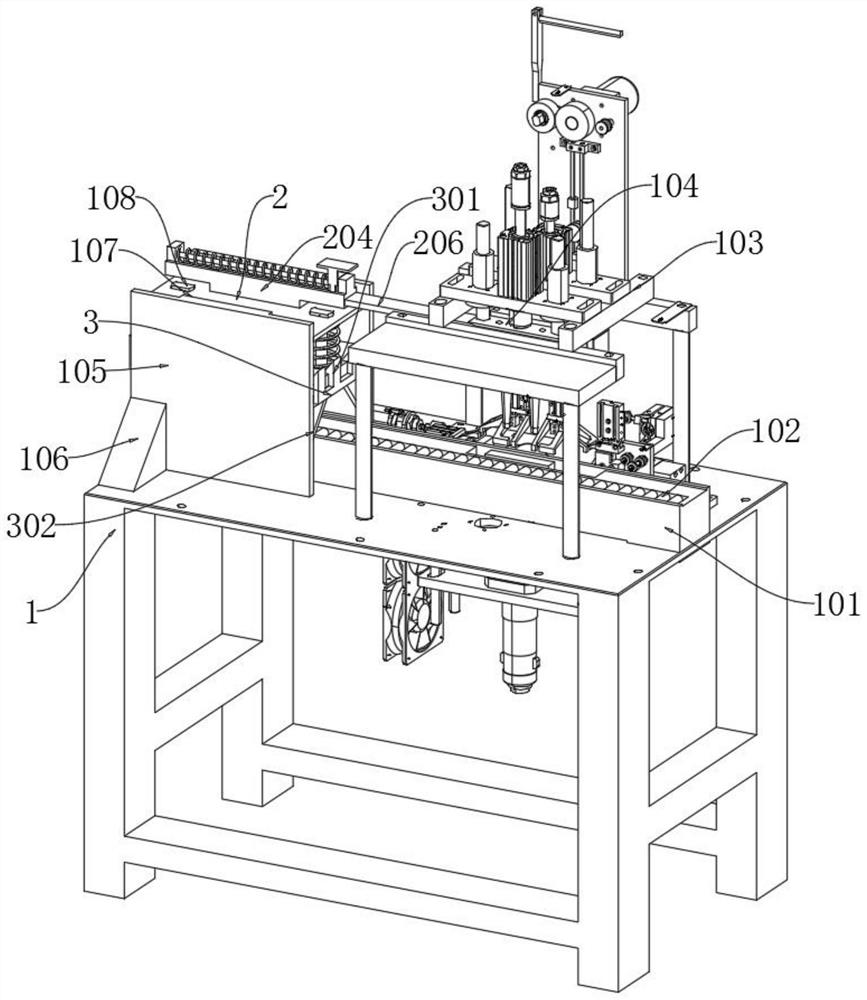

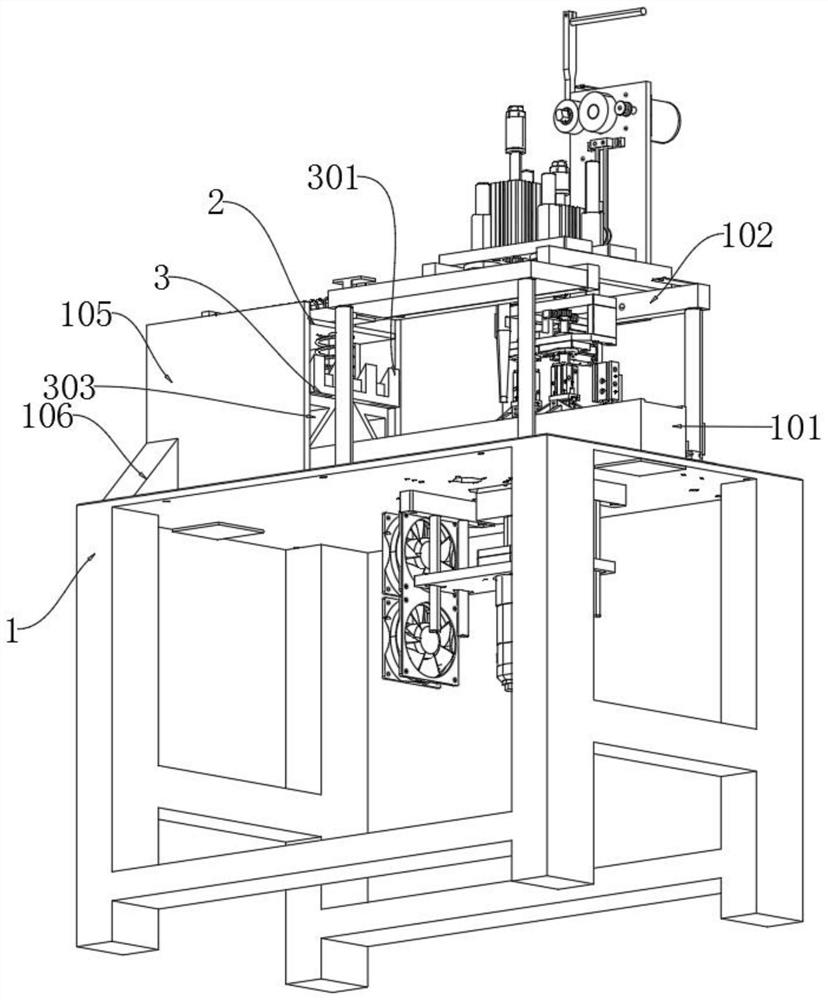

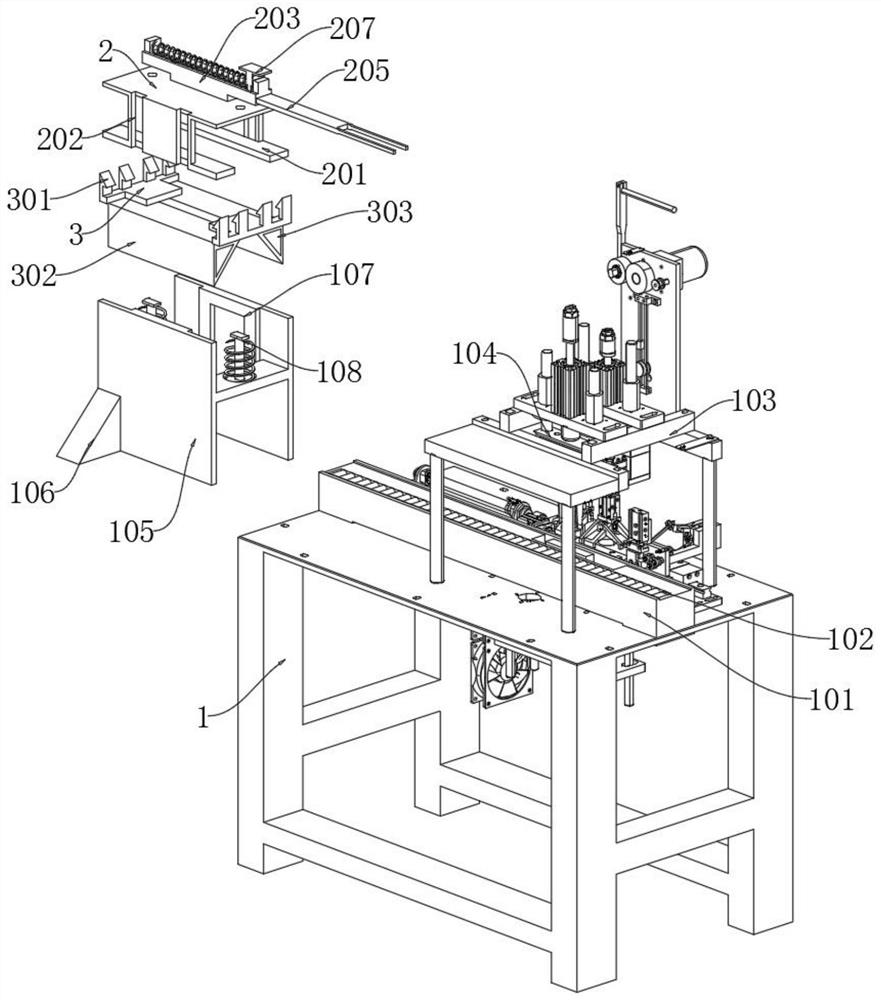

[0030] Example: Please refer to Figure 1 to Figure 8 :

[0031] The present invention proposes a production and processing mechanism based on the connection of ear straps for the production of flat masks, including: a main body 1; the main body 1 is the main body of the production and processing mechanism, and the main body 1 is a rectangular structure, which can make the device stably supported and used. The main body 1 includes: Mounting part 105, the mounting part 105 is made up of two rectangular plates, and the inner two ends of the mounting part 105 are connected by two rectangular plates, so that the mounting part 105 can firmly support and install the moving part 2 and the connecting part 3, and the mounting part 105 is fixed on On the top side of the main body 1, the mounting part 105 is above the guide part 101, so that the welding strength of the mask passing above the guide part 101 can be detected; the moving part 2, the moving part 2 is a rectangular plate structur

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap