High-voltage line foreign matter removing device and method

A technology for removing foreign matter and high-voltage lines, applied in cleaning methods and appliances, chemical instruments and methods, overhead lines/cable equipment, etc., can solve problems such as high-voltage line paralysis and high-voltage line threats, and achieve fast removal speed, good effect, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

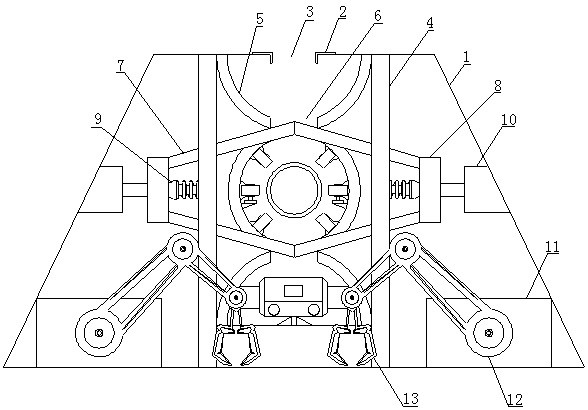

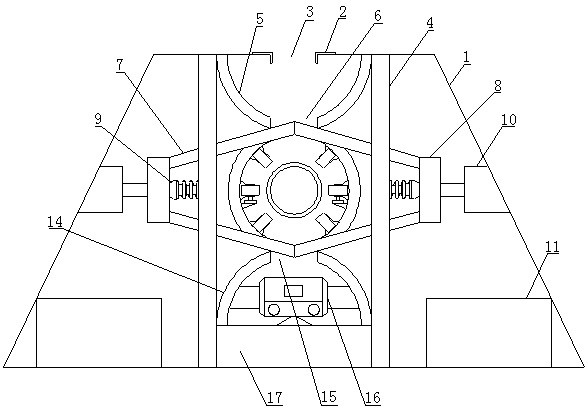

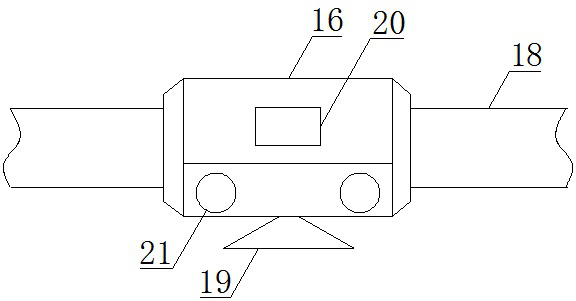

[0024] Such as Figure 1-4 As shown, a high-voltage line foreign matter removal device and method include a body 1 and a removal assembly 16, an inlet 3 is arranged above the body 1, corner seats 2 are arranged on the left and right sides of the inlet 3, and the The left and right sides of the main body 1 are provided with columns 4, the first elastic clip 5 is arranged above the inner side of the column 4, and the first clamping groove 6 is arranged below the first elastic clip 5. The inside of the main body 1 is provided with telescopic rods 10 on the left and right sides, and the inner side of the telescopic rods 10 is provided with a fixed plate 8, and the inner side of the fixed plate 8 is provided with a spring assembly 9, and the upper and lower sides of the spring assembly 9 Both are provided with brackets 7, and the inner sides of the brackets 7 are provided with cover plates 22, the inner sides of the cover plates 22 are provided with drive wheels 23, and the drives 24

Embodiment 2

[0028] Such as Figure 1-4 As shown, a high-voltage line foreign matter removal device and method include a body 1 and a removal assembly 16, an inlet 3 is arranged above the body 1, corner seats 2 are arranged on the left and right sides of the inlet 3, and the The left and right sides of the main body 1 are provided with columns 4, the first elastic clip 5 is arranged above the inner side of the column 4, and the first clamping groove 6 is arranged below the first elastic clip 5. The inside of the main body 1 is provided with telescopic rods 10 on the left and right sides, and the inner side of the telescopic rods 10 is provided with a fixed plate 8, and the inner side of the fixed plate 8 is provided with a spring assembly 9, and the upper and lower sides of the spring assembly 9 Both are provided with brackets 7, and the inner sides of the brackets 7 are provided with cover plates 22, the inner sides of the cover plates 22 are provided with drive wheels 23, and the drives 24

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap