Sewage drainage pipeline system

A technology for drainage pipes and sewage, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as hidden safety hazards, blockage of drainage pipes, etc., and achieve the effect of reducing maintenance costs, reducing impurities, and improving cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

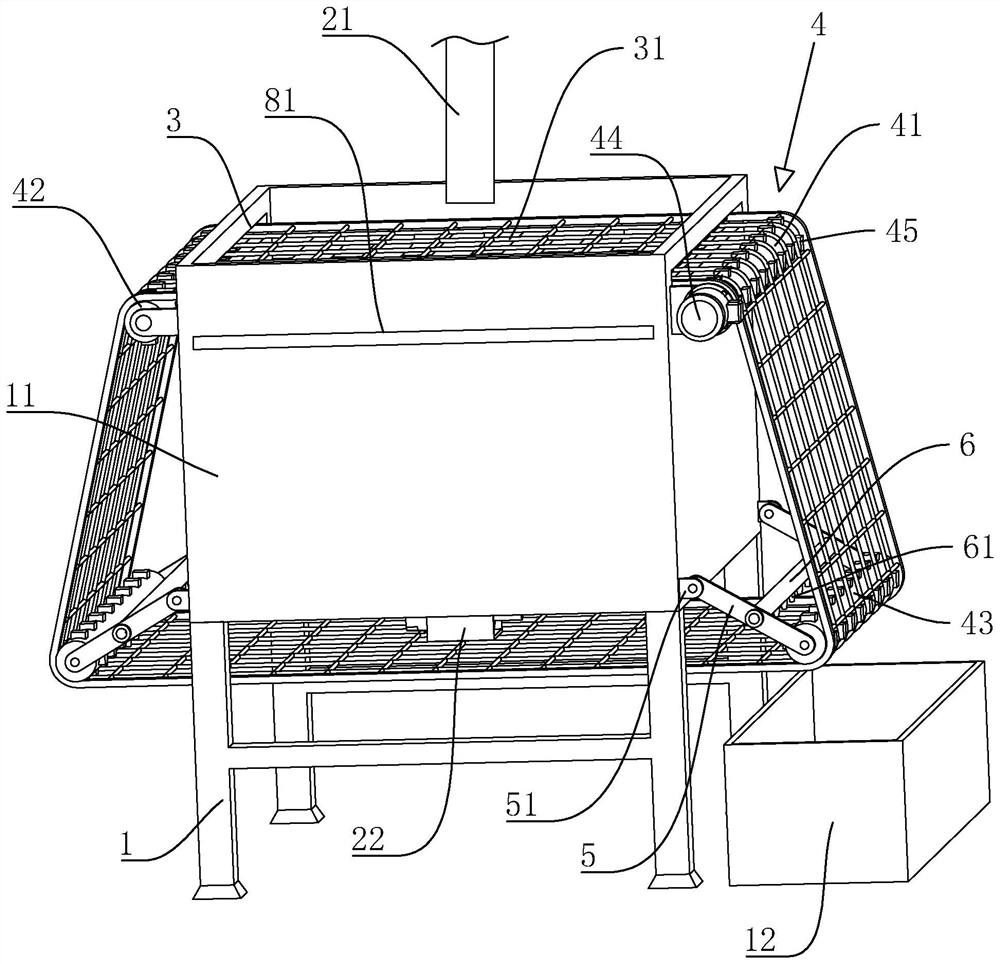

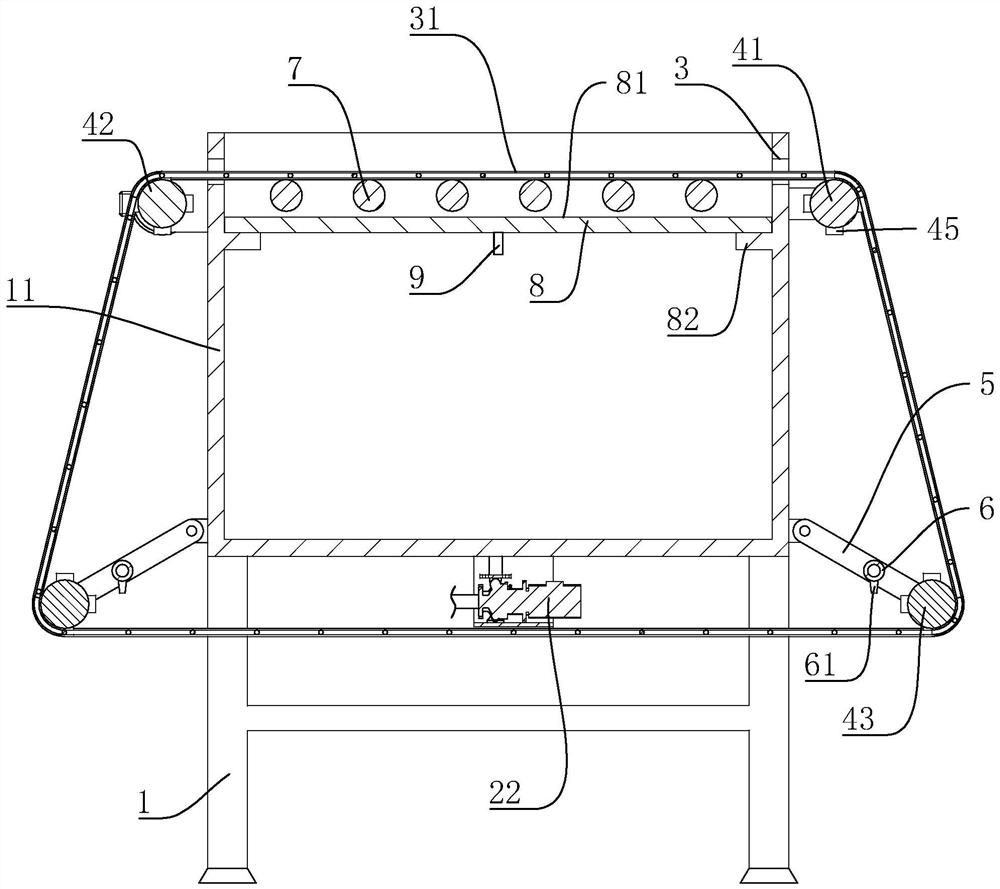

[0034] The following is attached Figure 1-2 The application is described in further detail.

[0035] The embodiment of the present application discloses a sewage drainage pipeline system. refer to figure 1 and figure 2, which includes a bracket 1, a water storage tank 11, a water inlet pipe 21 and a drainage pipe device 22, the water inlet pipe 21 is used to collect domestic sewage, and the water inlet pipe 21 is located above the water storage tank 11. The bracket 1 is fixedly arranged at the four top corners of the bottom wall of the water storage tank 11, the bracket 1 is used to support the water storage tank 11, the sewage flows into the water storage tank 11 through the water inlet pipe 21, and the drainage pipe device 22 is connected to the At the bottom of the water storage tank 11 , the drainage pipe device 22 can discharge the sewage collected in the water storage tank 11 .

[0036] refer to figure 1 and figure 2 A group of transport holes 3 are provided symmet

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap