Efficient calibration system for air flow meter of fuel cell and control method of efficient calibration system

An air flow meter and fuel cell technology, which is applied in the direction of testing/calibrating volume flow, etc., can solve the problems of low precision, many constraints, and large errors, and achieve the effects of suppressing errors, accurately calibrating coefficients, and eliminating measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

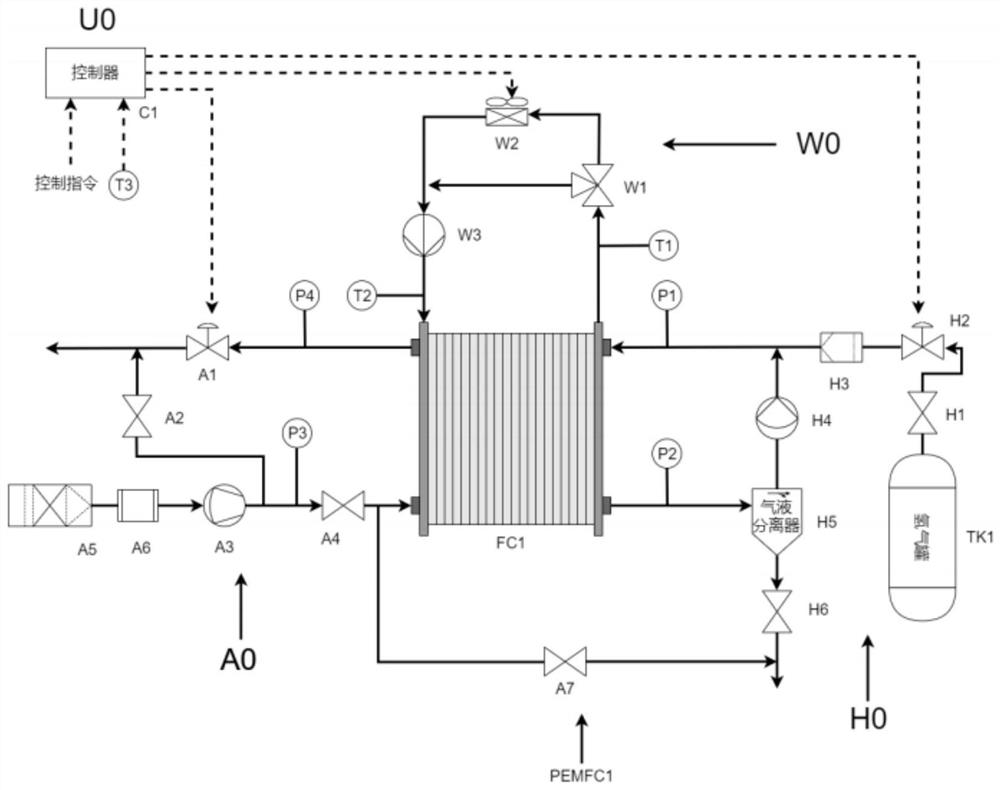

[0035] see Figure 1-4 The present invention provides a technical solution: a fuel cell air flow meter high-efficiency calibration system, including an air supply module AO, a hydrogen supply module HO, a heat dissipation module WO, a control module UO and a PEMFC1 fuel cell, and the air supply module AO includes an air filter A5, air compressor A3, back purge valve A6, air inlet valve A4, air outlet valve A2, bypass valve A2, purge relief valve A7, air inlet pressure sensor P3, outlet pressure sensor P4 and interconnecting pipes road composition.

[0036]Air supply module A0 includes air filter A5, air compressor A3, A6 air flow meter, air inlet valve A4, air outlet valve A1, bypass valve A2, purge relief valve A7, air inlet pressure sensor P3, outlet pressure The sensor P4 is composed of interconnected pipelines. The air filter A5 filters out impurities and dust in the air, and controls the air delivery pressure and flow through the air compressor A3. The air inlet valve A4 i

Embodiment 2

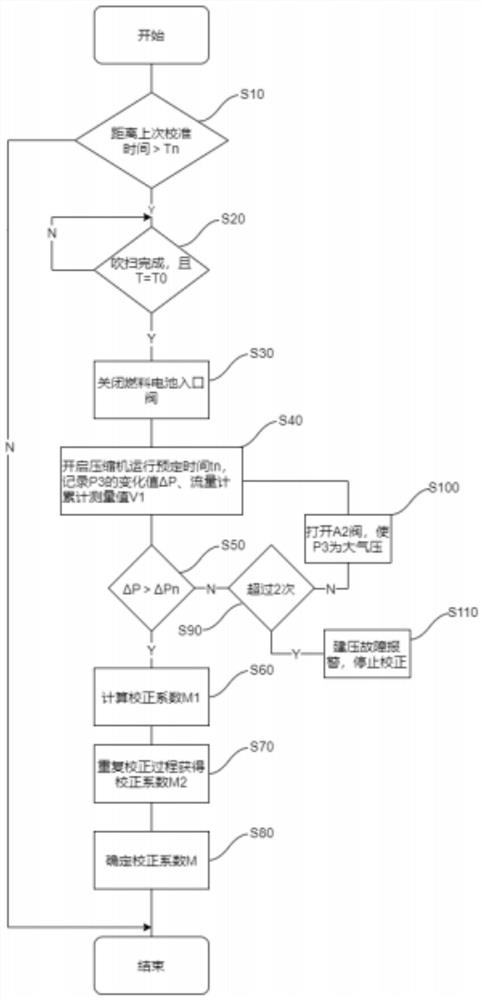

[0043] see Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a control method for an efficient calibration system of a fuel cell air flowmeter, comprising the following steps:

[0044] Step 1: First, S10 judges whether the fuel cell has passed a certain time Tn from the last calibration, such as 7d, and the setting can be changed. If not, that is, S10 is No, then the control is ended. If the stop signal S10 is Yes, then Carry out S20 control;

[0045] Step 1: Judging whether the purging is completed, and the internal temperature T of the fuel cell is the same as the external air temperature T0, or the difference between the two is within a certain range, so as to reduce the subsequent calculation error, the system maintains this judgment until it is yes and enters S30;

[0046] Step 1: Close the fuel cell inlet valve A4 to form a closed pipeline between the compressor A3 and the fuel cell inlet valve. The volume of this clos

Embodiment 3

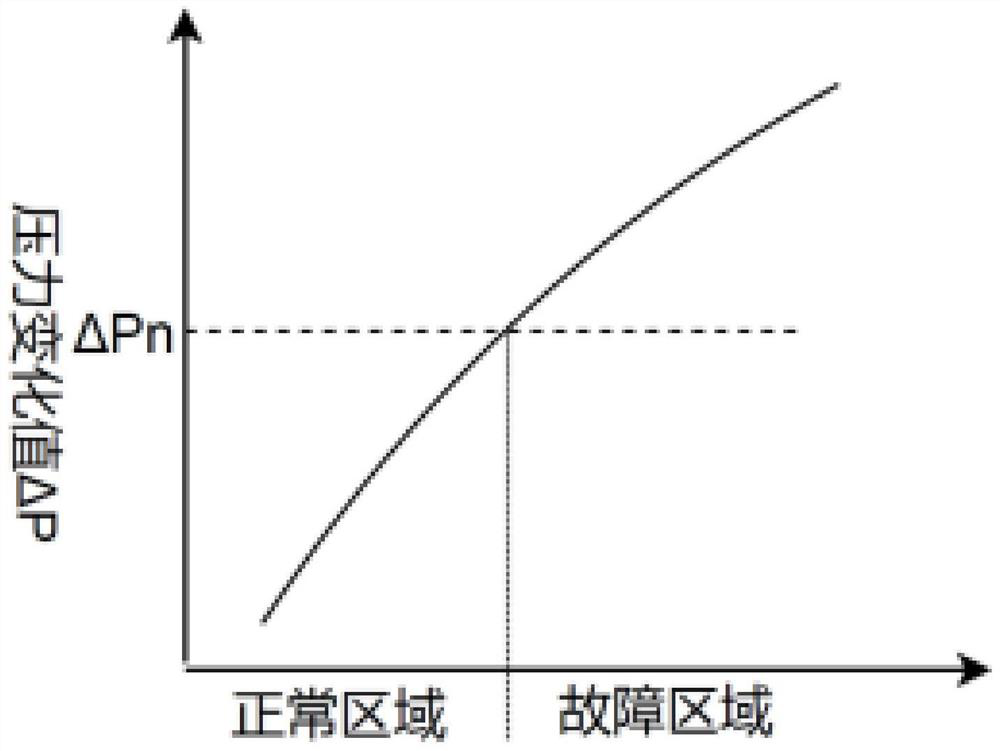

[0057] see Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: image 3 It is a modification of the present invention. Compared with the first embodiment, S90-110 is replaced by S120-150. Other control and fuel cell structure principles are the same as the first embodiment. S120 judges the absolute value of the difference between the calibration coefficients obtained twice. Whether it is lower than the preset value ΔM, ΔM is set according to the calculation deviation value caused by possible errors in the two identical calibration processes, such as measurement errors, if it is judged, then enter S80 to perform the same operation as the first embodiment , otherwise go to S130, the reason is as follows, when the absolute value of the difference between the two obtained calibration coefficients is higher than the set threshold, it means that there is a non-negligible error in the two calibration processes, S130 judges whether thi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap