Asynchronous motor

A technology for asynchronous motors and stators, applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of motor efficiency limitation, insignificant efficiency improvement, large reactive power loss, etc., and achieve the effect of improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

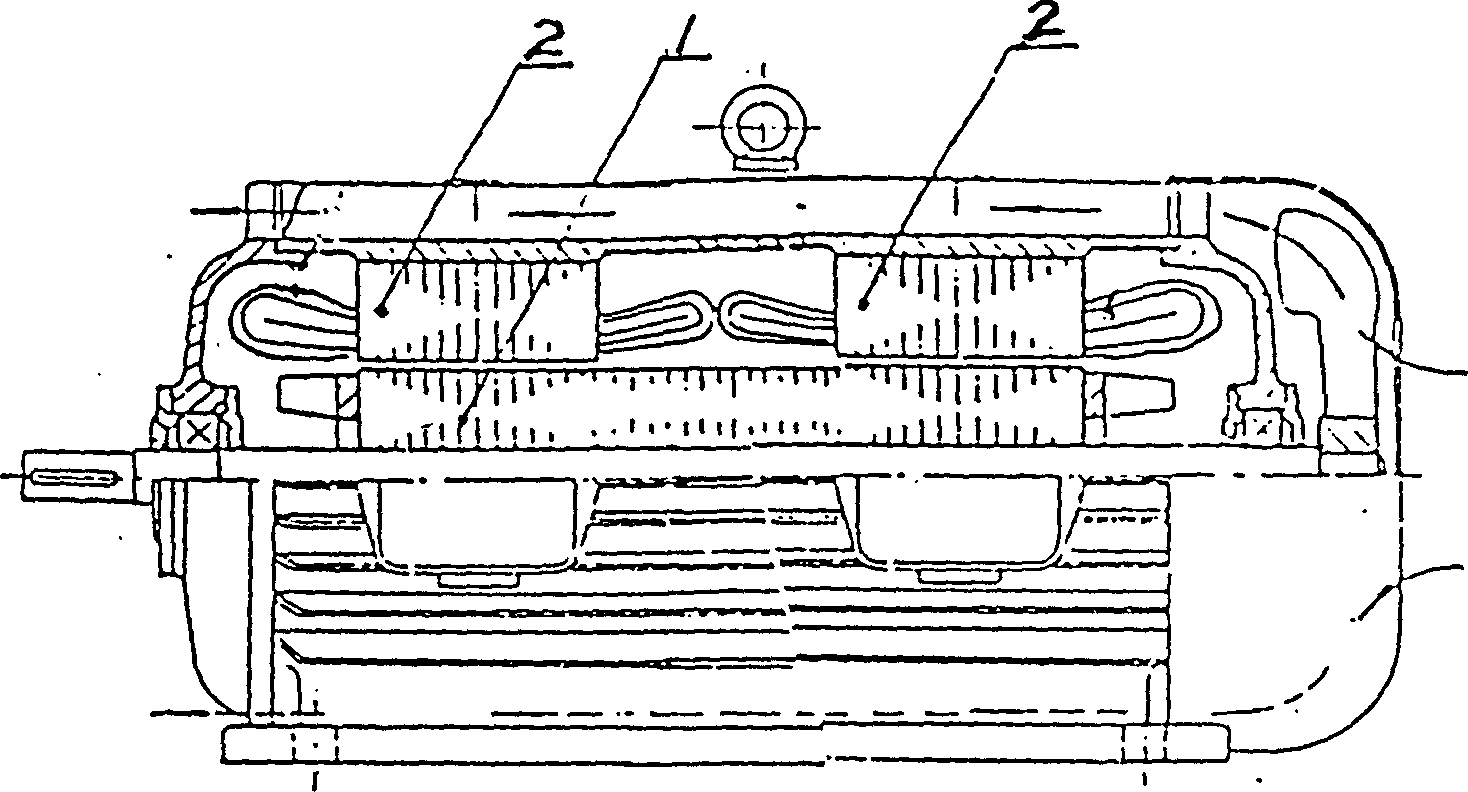

[0020] Such as figure 1 In the illustrated embodiment, the motor includes a rotor core and two stator cores.

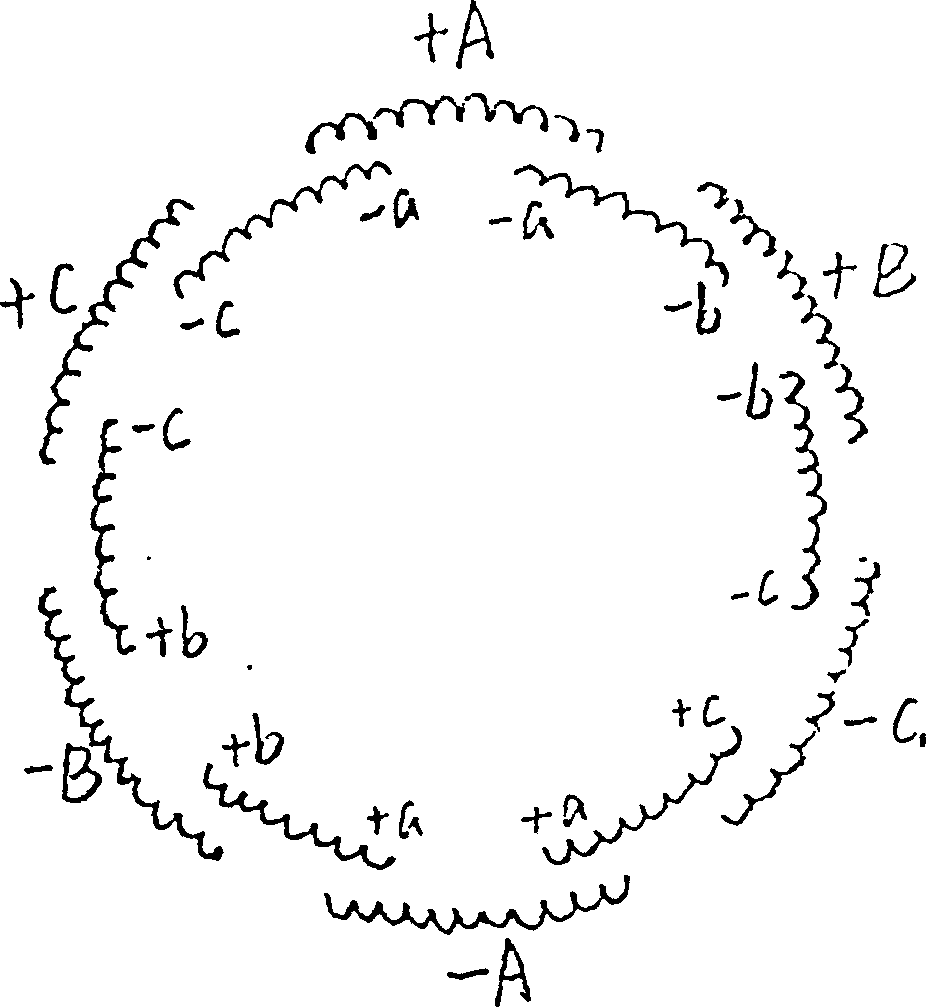

[0021] Such as figure 2 In the straight-line structure schematic diagram of a set of main windings and auxiliary windings shown, the main windings and auxiliary windings are laid across phases.

[0022] Such as Figure 5 The example shown is in the figure 1 On the basis of the structure, the two stator cores are divided into a fixed core 4 and a rotating core 5, the rotation angle can be adjusted by the worm wheel 6 and the worm 7, and the rotating core can be fixed at the required relative angle position by the positioning screw 8 , so that the two stator cores are staggered by an electrical angle. The structure of the set screw 8 is as Figure 6 Shown, ball 9 is installed at its bottom, and it can cooperate with the locating groove on the rotating iron core.

[0023] Such as Figure 7 Shown is a schematic diagram of a broken-line winding, a set of main winding

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap