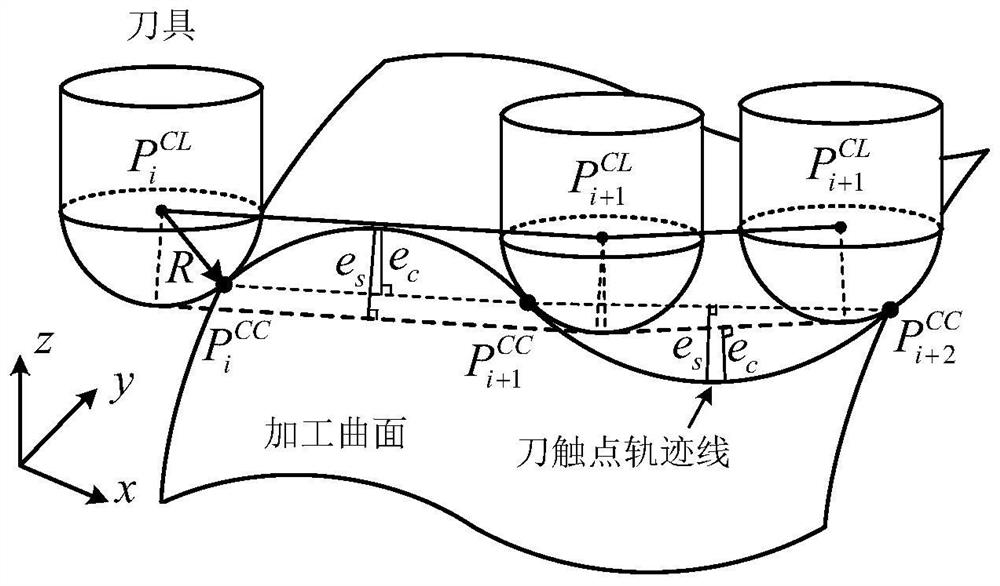

Free-form surface three-axis ball-end cutter equal approximation error finish machining tool path generation method

A technology for approximating errors and surfaces, applied in the field of CNC machining toolpath generation, it can solve the problem of inability to generate other error toolpaths, etc., and achieve the effect of high-efficiency generation, reduction of calculation time, and reduction of iterations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

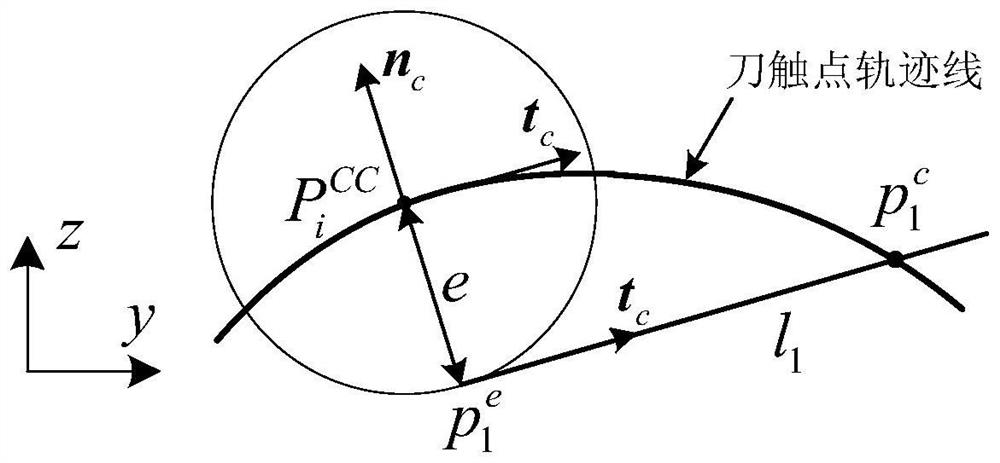

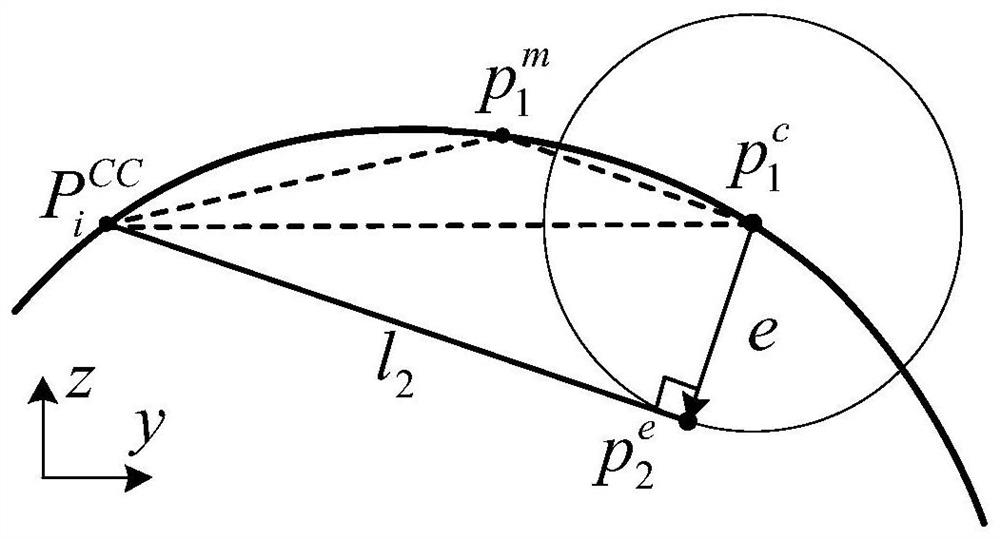

Method used

Image

Examples

Embodiment

[0072] A typical implementation example of the present invention is as follows: below:

[0073] by Figure 7 (A) The curved surface is an example of the knife rail. The surface size is 120mm × 140mm × 38mm. The direction of the row distance is the positive direction of the X axis, and the error knife rail generated by generated is like Figure 7 (B) Show. In comparison, the step -long screening method is adopted and the number of initial knives per line of each row is selected to generate a knife rail, such as Figure 8 Show, evenly select the 7 -line knife rail, and its approximation error is distributed like Figure 9 (A), (b) shown, it can be seen that its distribution is uneven. The approximate error distribution of the error knife rail is like Figure 9 (C) Show, except for the last knife point corresponding to the end point of the trajectory of each row of knife (for a fixed point, cannot be adjusted), the approximation error of all other knife points is within the interval range...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap