Hollow ball plug and its manufacturing method

A manufacturing method and hollow technology, which is applied in the field of ball plugs and their casting, can solve the problems of hollow ball plugs such as heavy weight, unstable quality, and large thickness differences, and achieve the effects of material reduction, weight reduction, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

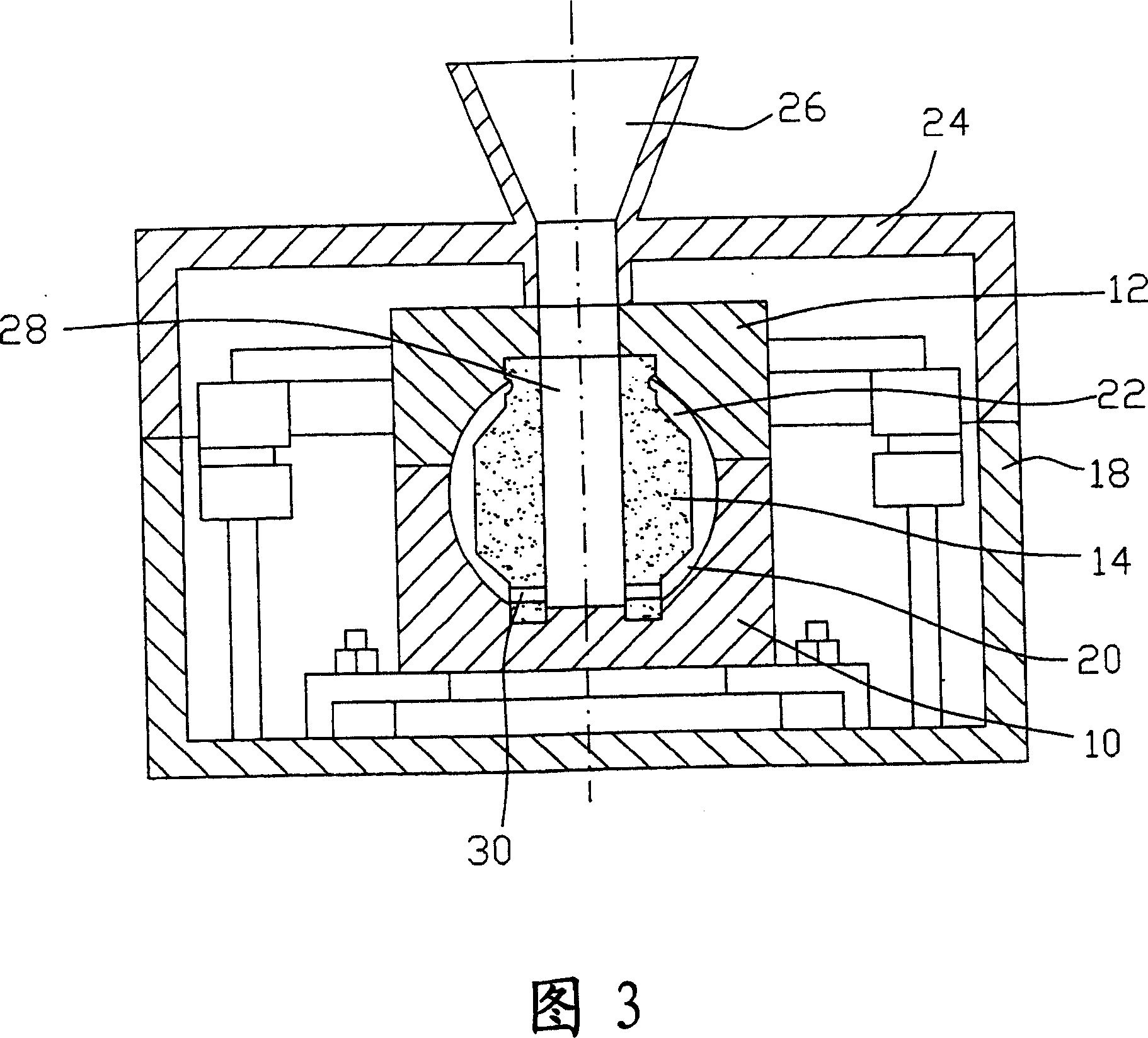

[0029] In order to have a more detailed and definite understanding of the technology and means on the object and method of the present invention, a preferred specific embodiment of the present invention is cited and described as follows in conjunction with the drawings:

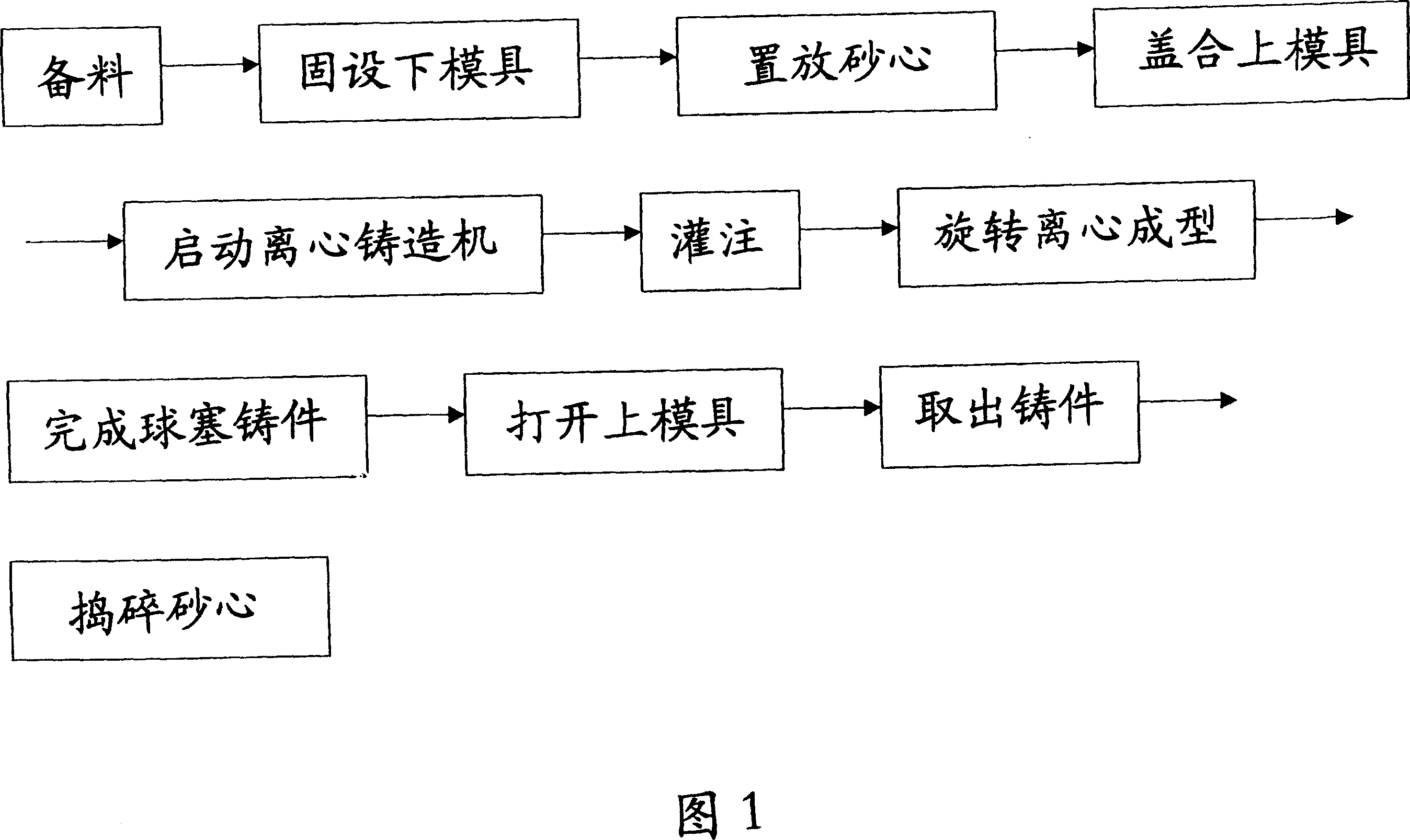

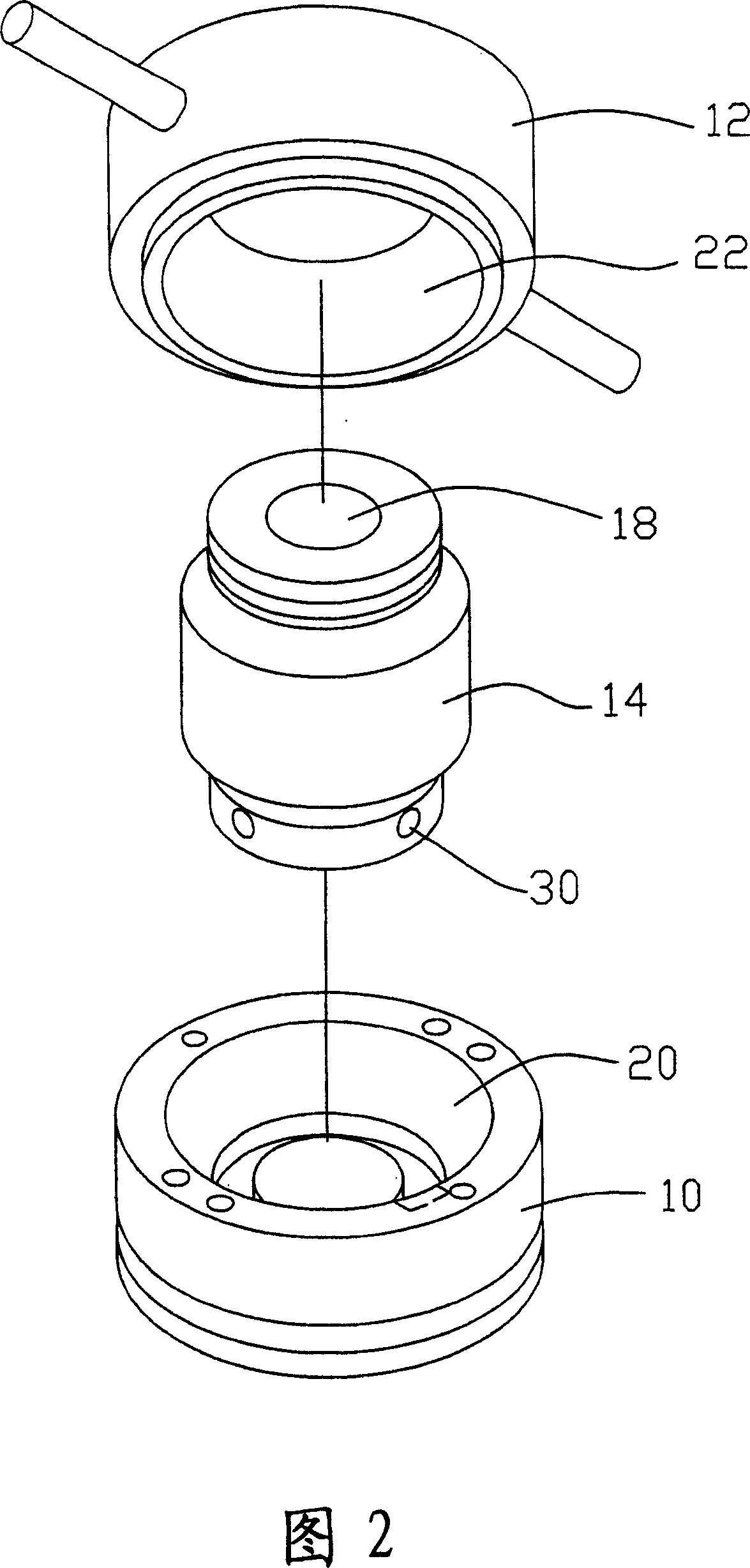

[0030] Please refer to shown in Fig. 1, it is a kind of asymmetric type vertical centrifugal casting method flow chart of the present invention, and cooperate to refer to shown in Fig. 2, Fig. 3, Fig. 4 and Fig. 5, Fig. 6, its whole manufacturing process includes the following Steps:

[0031] Material preparation: heating the metal material until it melts into a liquid state;

[0032] Fix the lower mold: the lower mold cavity 20 is preset as the lower mold 10 in the shape of the lower half of the ball plug, and the lower mold 10 is locked and fixed in the centrifugal casting machine 18;

[0033] Place the sand core: the sand core 14 whose shape is the hollow shape of the ball plug and has a central channel is p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap