Stirring fan mounting structure for microwave oven

A technology for installation structure and microwave oven, which is applied in household stove/stove, household heating, lighting and heating equipment, etc. It can solve the problems of complicated installation process and increased manufacturing cost, and achieve good stability, easy operation and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The installation structure of the microwave oven stirring fan of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

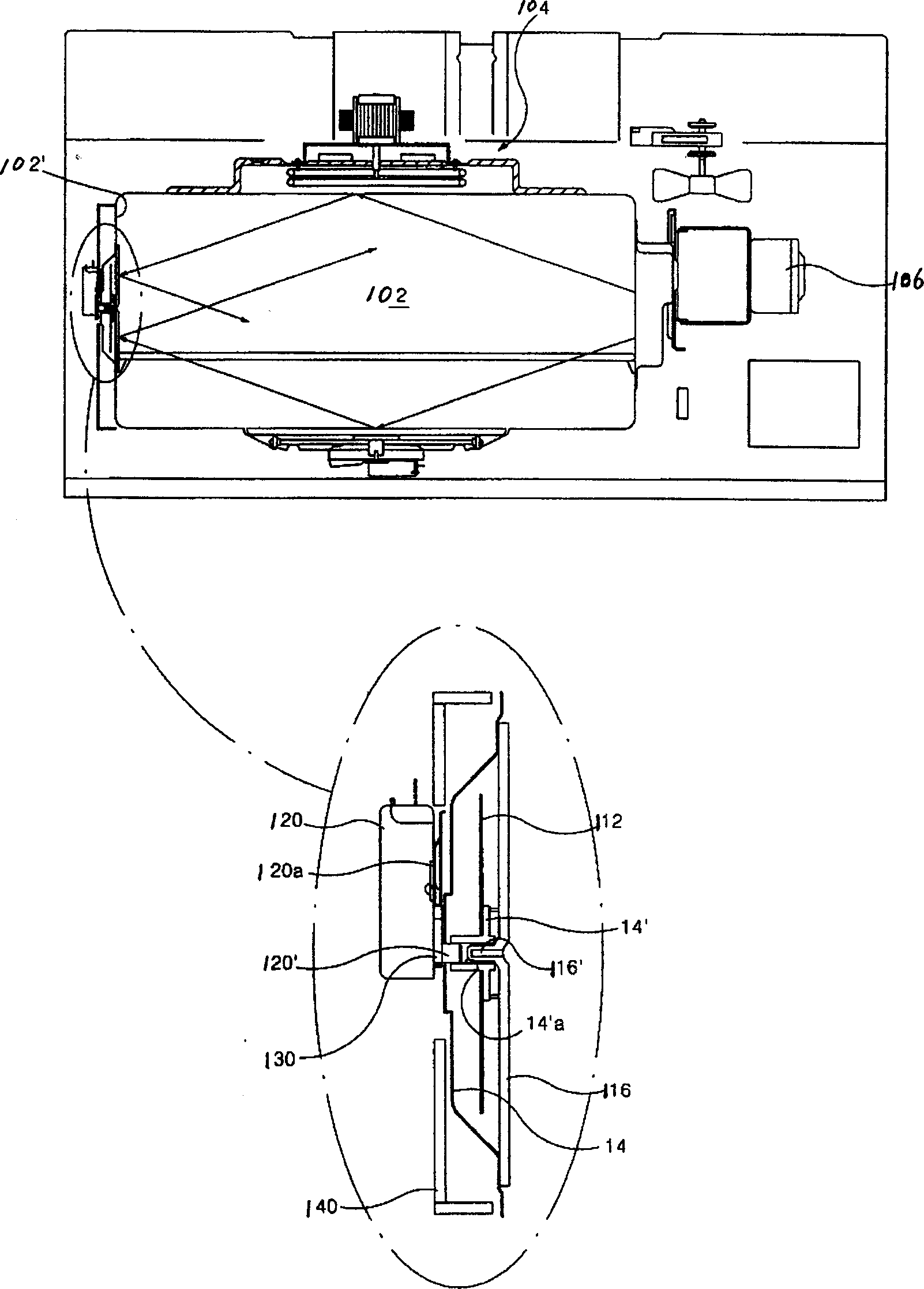

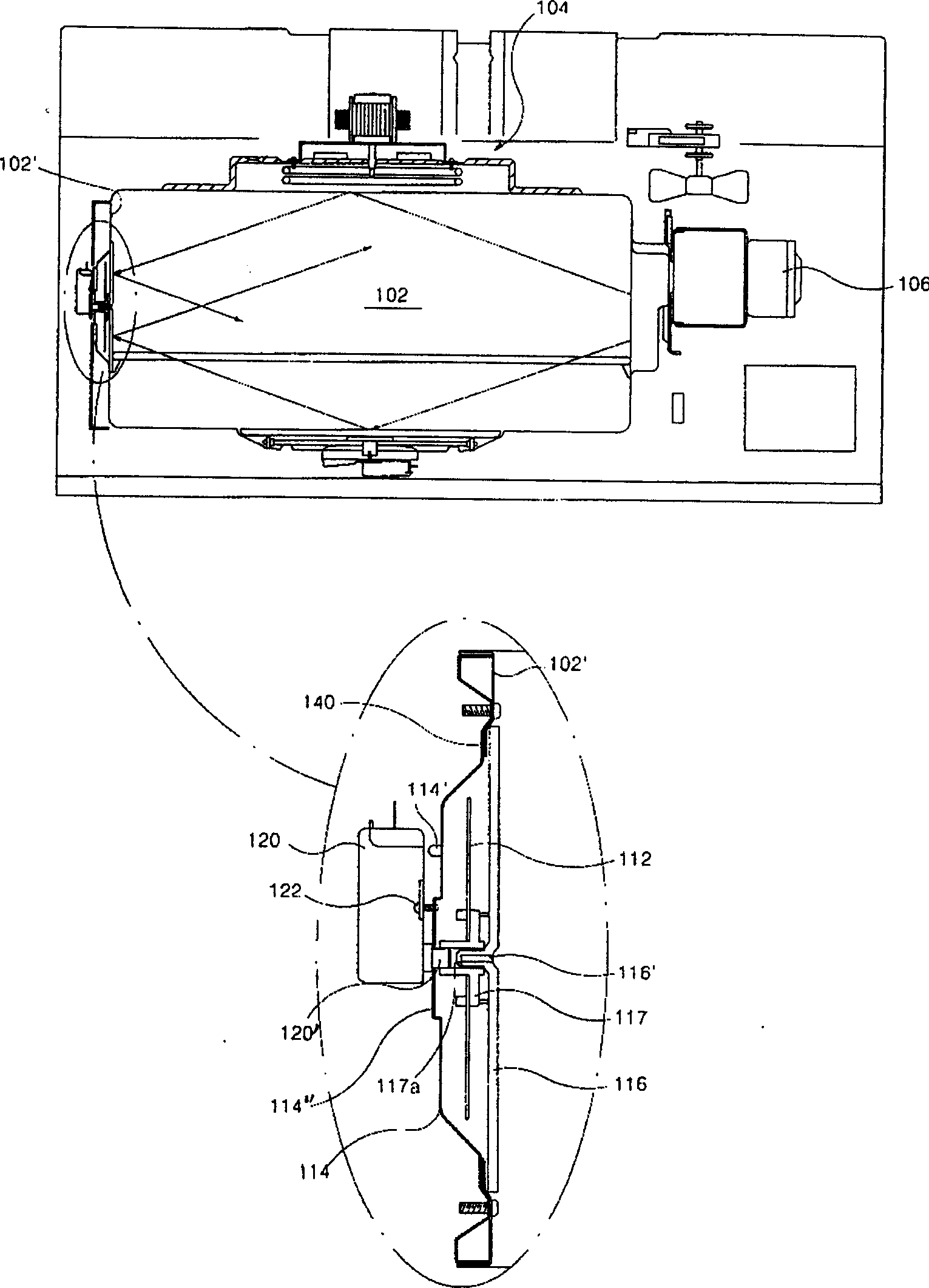

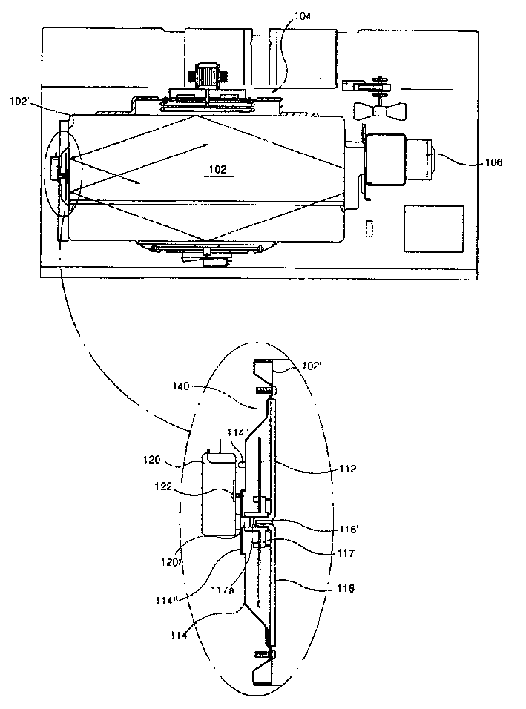

[0025] Such as figure 2 As shown, a convection heater assembly 104 is arranged on the top surface of the cooking chamber 102 of the microwave oven, a magnetron 106 is arranged on a side wall of the cooking chamber 102, and a magnetron 106 is arranged on the side wall 102' opposite to the magnetron 106 in the cooking chamber 102. A stirring fan 112 is provided. The function of the stirring fan 112 is to reflect the microwave generated by the magnetron 106 . The stirring fan 112 is driven by a fan motor 120 .

[0026] The installation structure of the stirring fan of the present invention comprises: stirring fan 112, heat insulating shell 140, side wall 102', support 117 and fan cover 116; The middle part of described side wall 102' has a circular hole, and heat insulating shell 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap