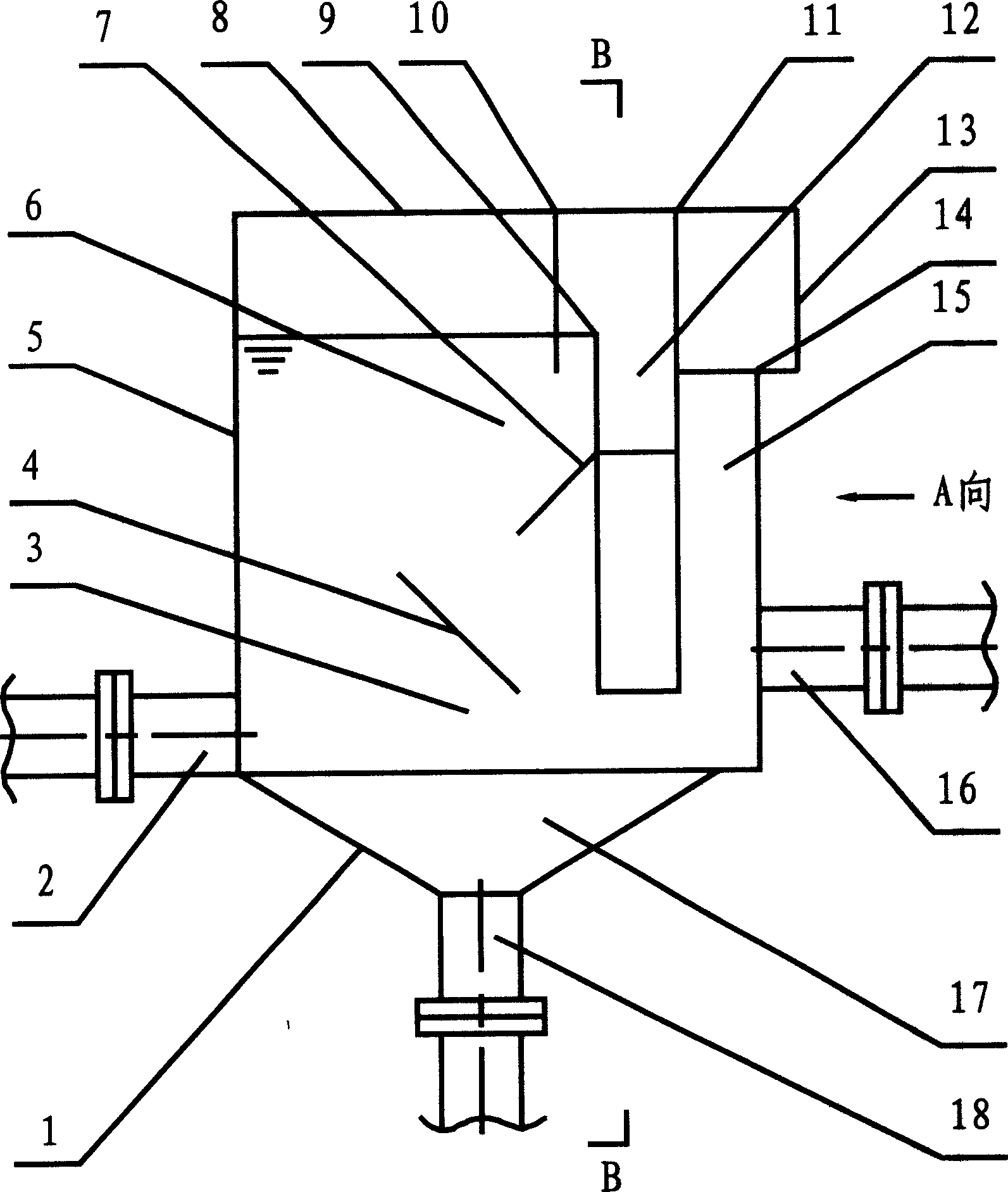

Sludge thicking dewatering equipment

A dewatering device and sludge thickening technology, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of long residence time, large floor space, large investment, etc., and achieve the effect of reducing equipment cost and processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The working process that the present invention carries out concentration dehydration to sludge is as follows:

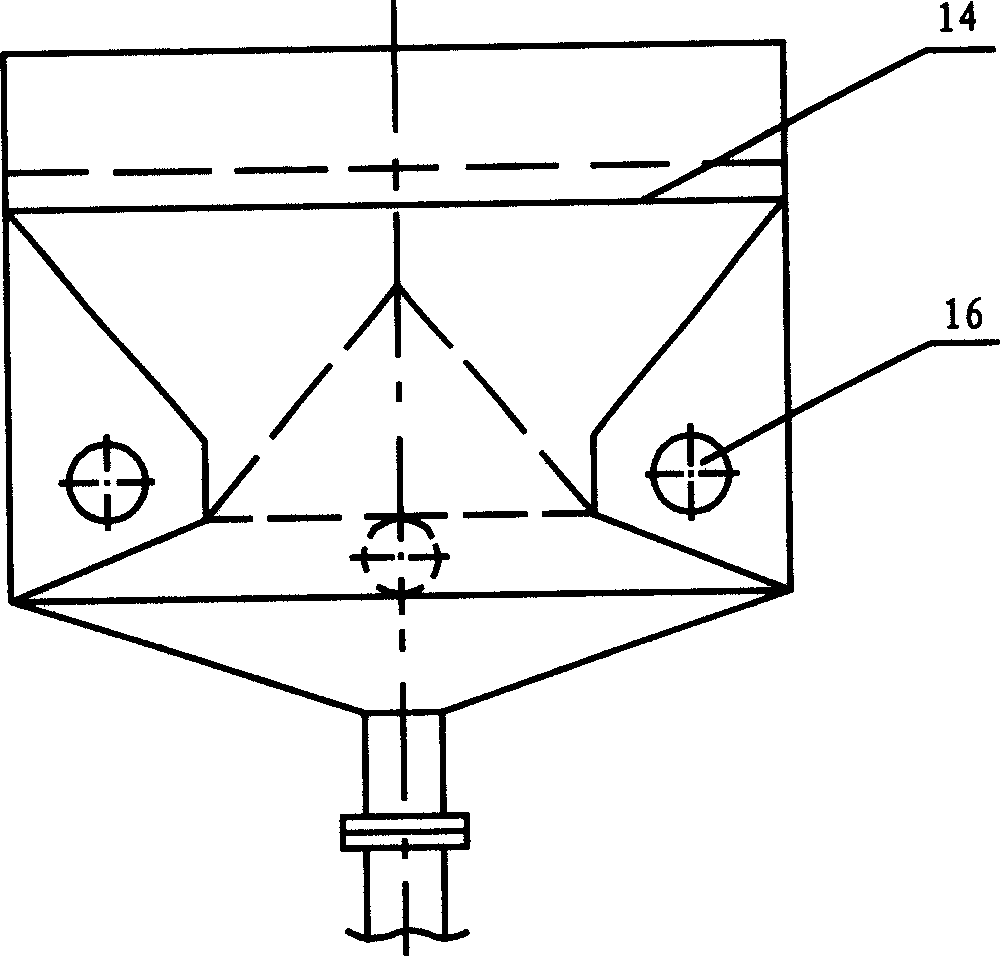

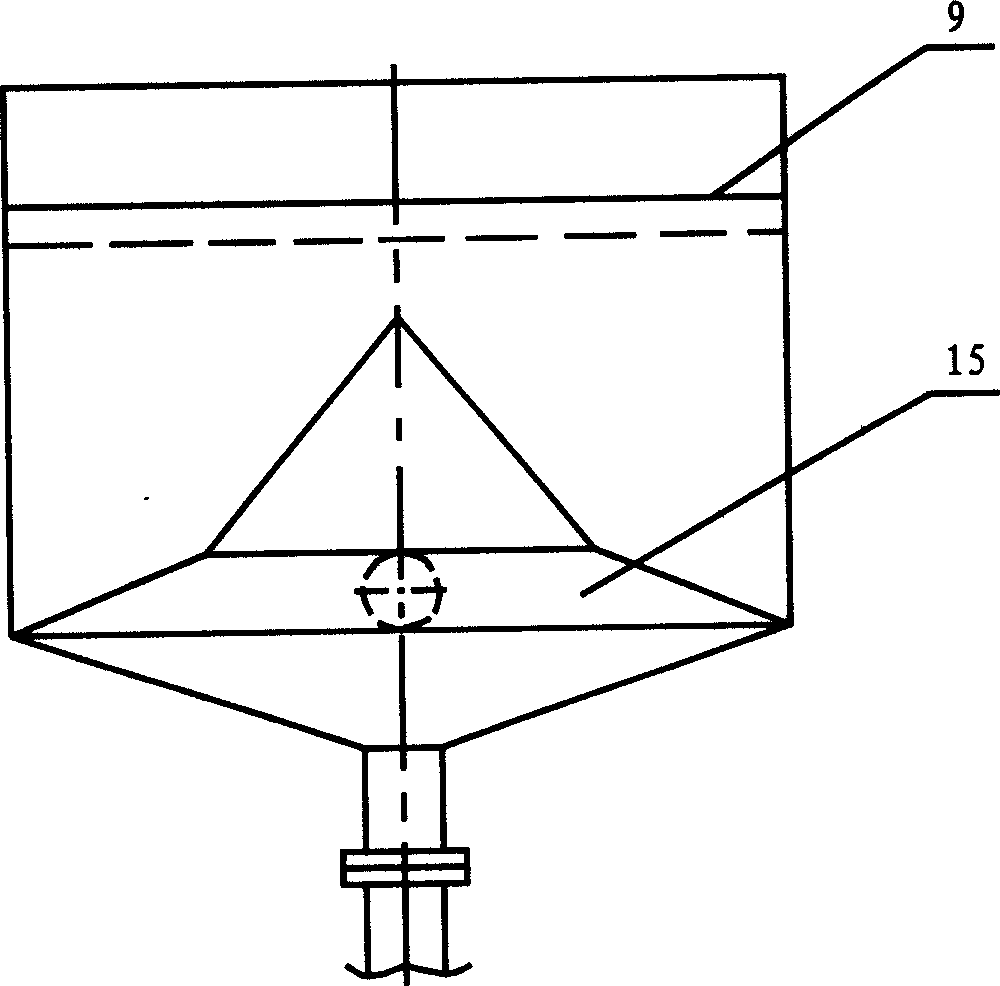

[0020] After dosing, the sludge that is completely mixed and has a certain flow rate enters the tank (5) under static pressure or pump pressure. Due to the sudden increase of the flow cross-sectional area, the flow rate will slow down sharply. Under the action of gravity, the specific gravity The lighter clear water will float up, and the sludge with heavier specific gravity will sink. Part of the sludge in the floating clean water will further settle into the sludge zone (17) in the thickening zone (3) behind the splitter plate (4), and part of the clear water in the sinking sludge will be concentrated in the thickening zone (3) behind the splitter plate (4). Zone (3) further ascends to Clearwater Zone (6). The diverter plate (4) has two functions: one, to improve the mud-water separation efficiency of the mud inlet; second, to reduce the interference of the mu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap