Small vacuum filling device

A vacuum filling and small-scale technology, which is applied in the direction of equipment for loading into pressure vessels, container filling methods, gas/liquid distribution and storage, etc. It can solve the problems of inconvenient installation of valve devices, small equipment capacity, small pipelines, etc., to achieve Increased uptime, reduced manufacturing costs, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

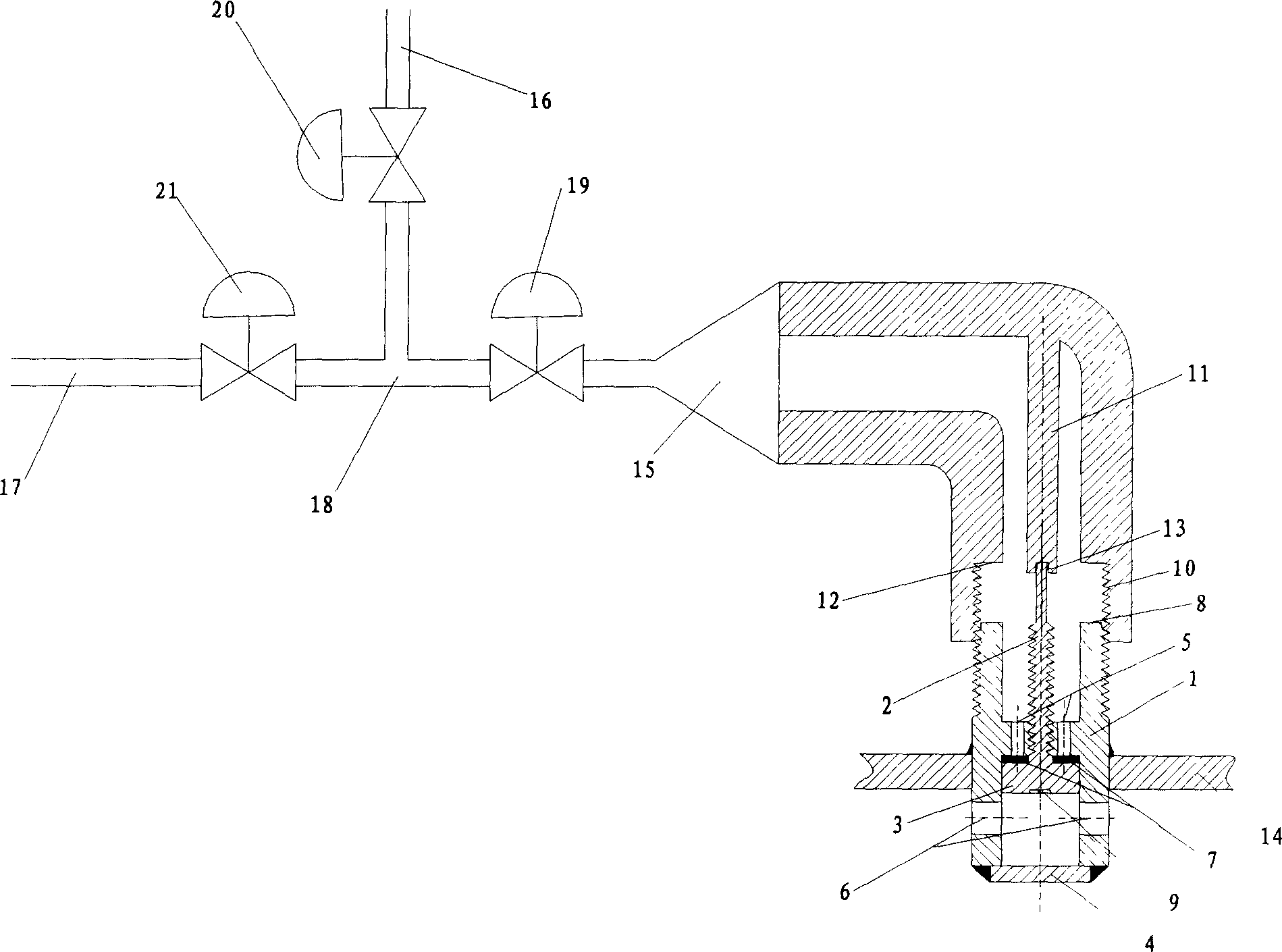

[0020] Such as figure 1 As shown, the small vacuum filling device of the present invention is composed of three parts, including a filling valve, a sealing pipe wrench, and a T-shaped valve pipe. The filling valve is mainly composed of a valve base 1, a valve stem 2, a cylindrical sealing body 3, and a The sliding cover 4 is composed of the valve base 1 in an H-shape, with threads in the middle of its transverse wall, the valve base 1 is connected with the valve stem 2 through the threads of the transverse wall, and the lower end of the valve stem 2 is integrated with the upper end of the cylindrical sealing body 3; The outer peripheral surface of the cylindrical sealing body 3 is in contact with the inner side of the side wall of the valve base body 1, and the first group of canned gas inlet holes 5 are opened on the t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap