Gas burner crown for kitchen hobs

A technology for gas stoves and hobs, which is applied in the field of gas stove crowns, and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

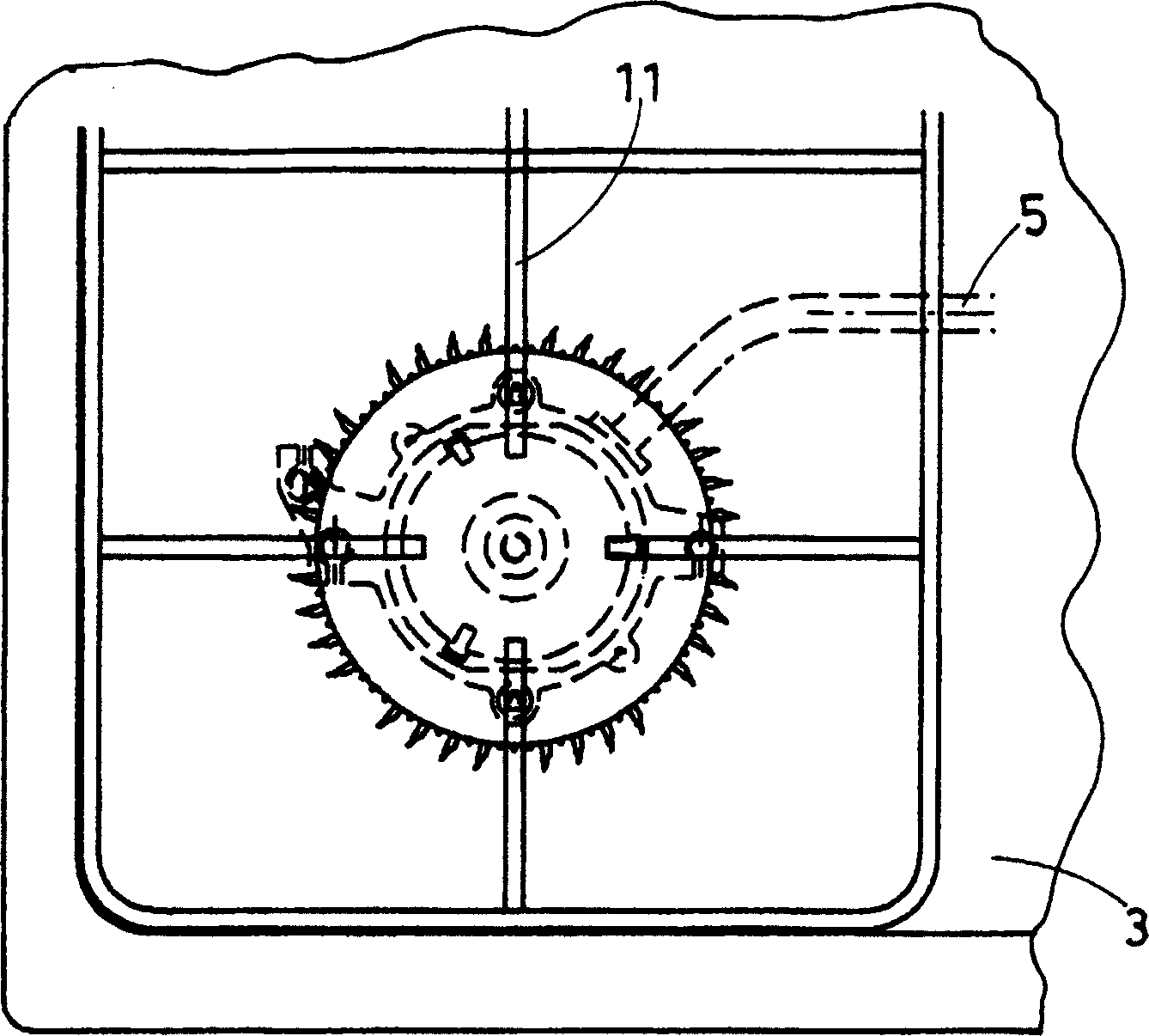

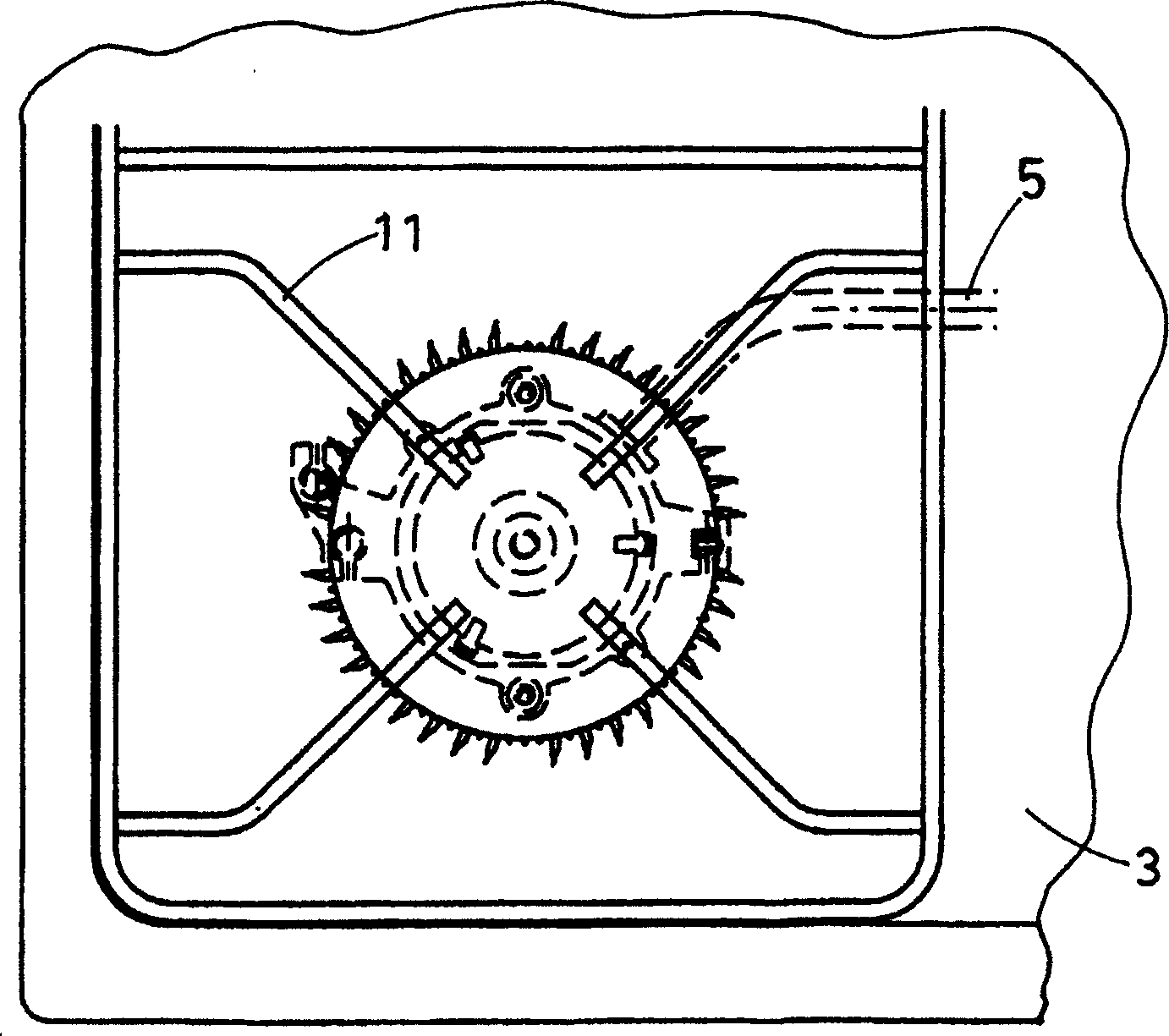

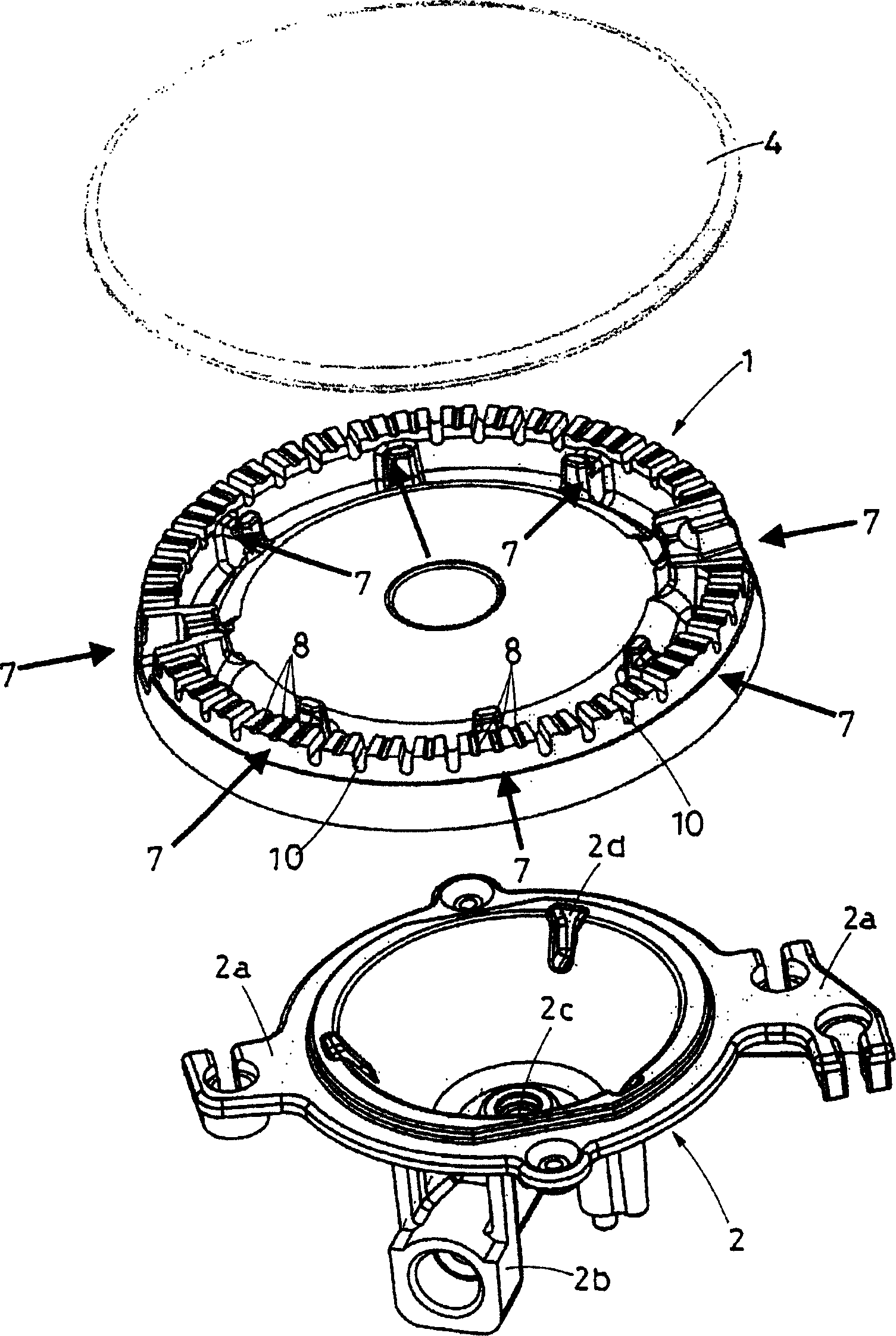

[0017] As shown in the aforementioned drawings cited, the furnace crown 1 of the present invention is designed for a traditional gas range, and its range body 2 has a peripheral bracket 2a for stably fixed under the hob 3, and a cover with a cover is placed on the peripheral bracket 4 for the furnace crown 1.

[0018] The stove body 2 has a radial nozzle 2 b extending outwards connected to the gas supply pipe 5 , and the nozzle is located below the stove frame 3 . The end of the nozzle 2b is a hole 2c at the bottom of the stove body 2, and internal grooves 2d are distributed at even intervals on the upper edge, which precisely accommodate the teeth located under the furnace crown 1, so as to prevent the furnace crown 1 from moving The kitchen range body 2 rotates freely.

[0019] The cover 4 is placed over the crown 1 which has a series of evenly spaced radial grooves which act as small gas burner nozzles from which small radial flames are produced.

[0020] The crown 1 of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap