Variable capacity rotary compressor

A rotary compressor and compressor technology, applied in the direction of rotary piston machines, rotary piston pumps, rotary piston/swing piston pump components, etc., can solve problems such as wear on the outer surface of the rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, preferred embodiments provided according to the present invention will be described in detail with reference to the accompanying drawings.

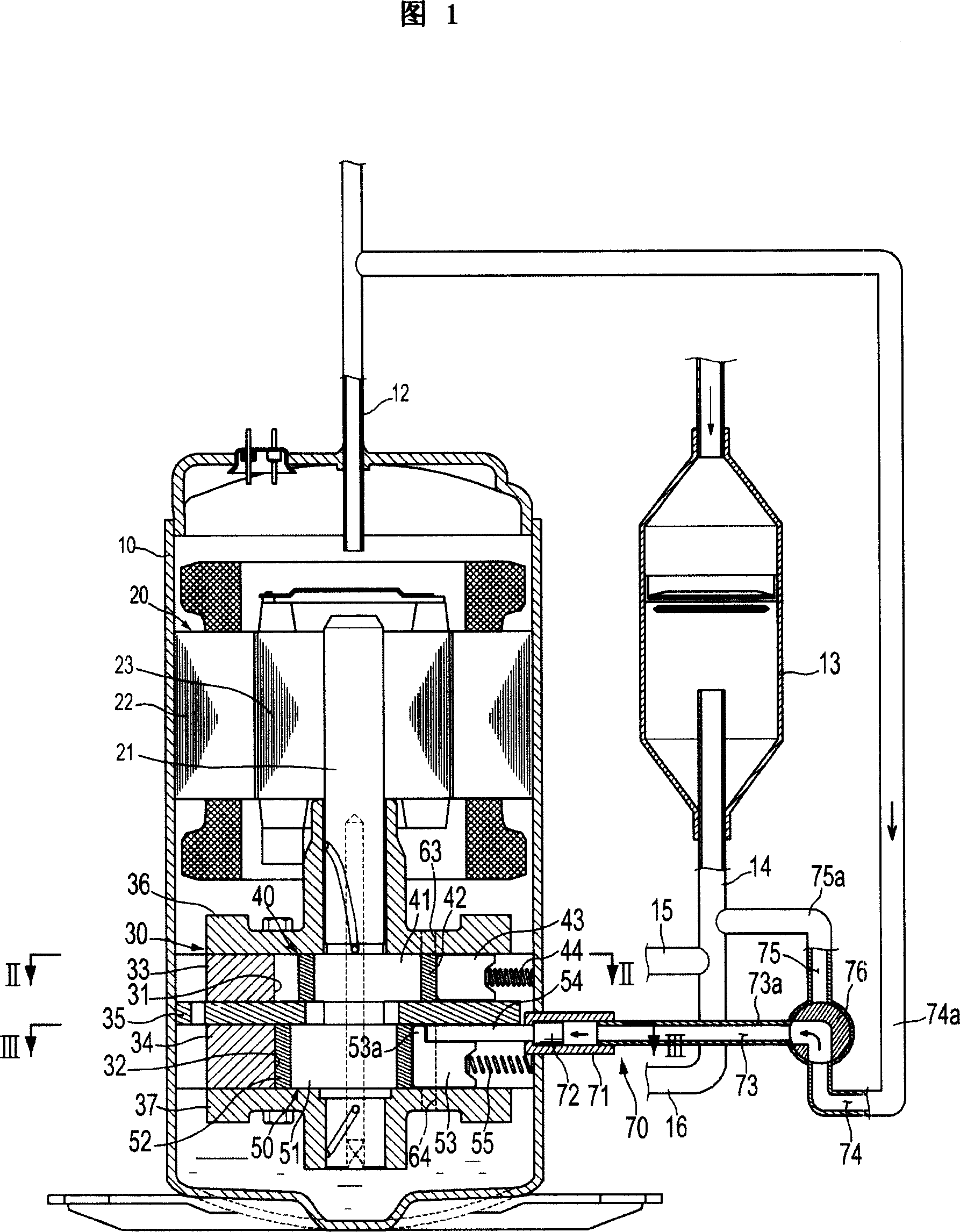

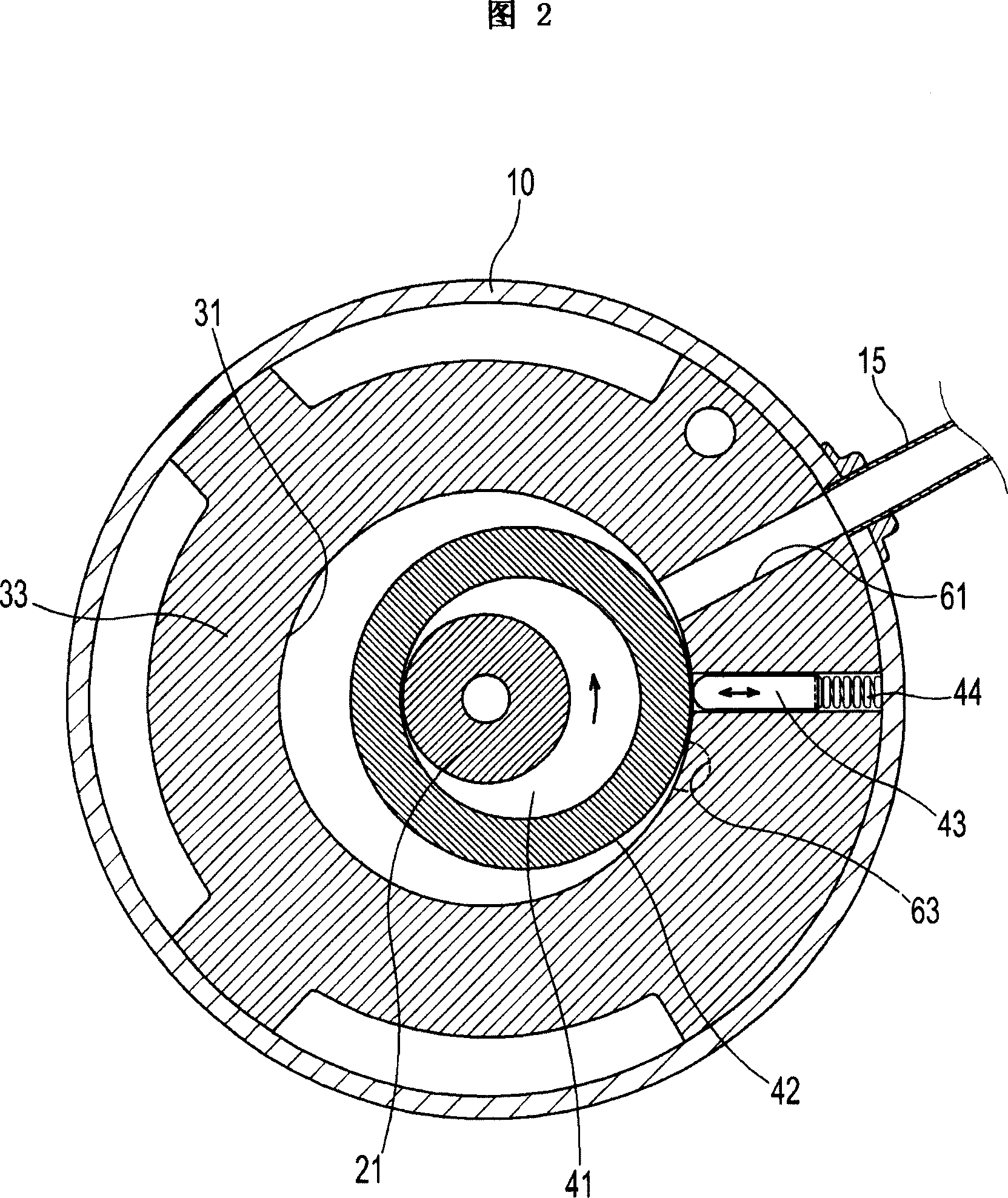

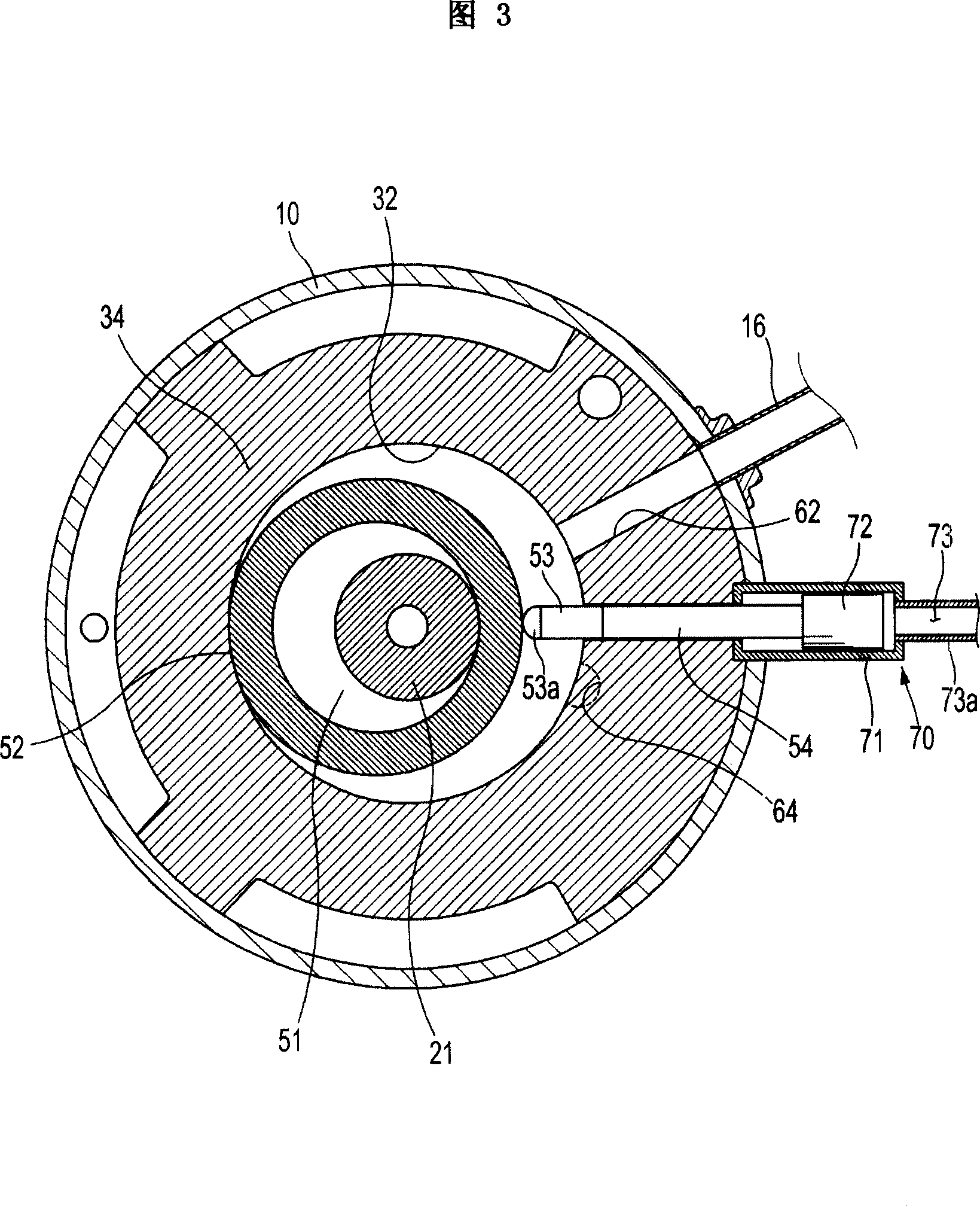

[0019] 1 to 5 show a variable capacity rotary compressor according to a first embodiment of the present invention. The variable capacity rotary compressor of the first embodiment, as shown in FIG. agency30.

[0020] The electric mechanism 20 includes a cylindrical stator 22 fixed on the inner surface of the sealed container 10 , and a rotor 23 rotatably disposed inside the stator 22 and coupled to the rotating shaft 21 at its center. Such a motor mechanism 20 rotates a rotor 23 when power is applied, and the rotor 23 in turn causes the rotation shaft 21 to rotate, thereby driving the compression mechanism 30 .

[0021] As shown in FIGS. 1 to 3 , the compression mechanism 30 includes an outer shell having a first compression chamber 31 and a second compression chamber 32 divided from each other, and housings respectively

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap