Universal saw

A technology of saw blades and shells, applied in the field of battery screwdrivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

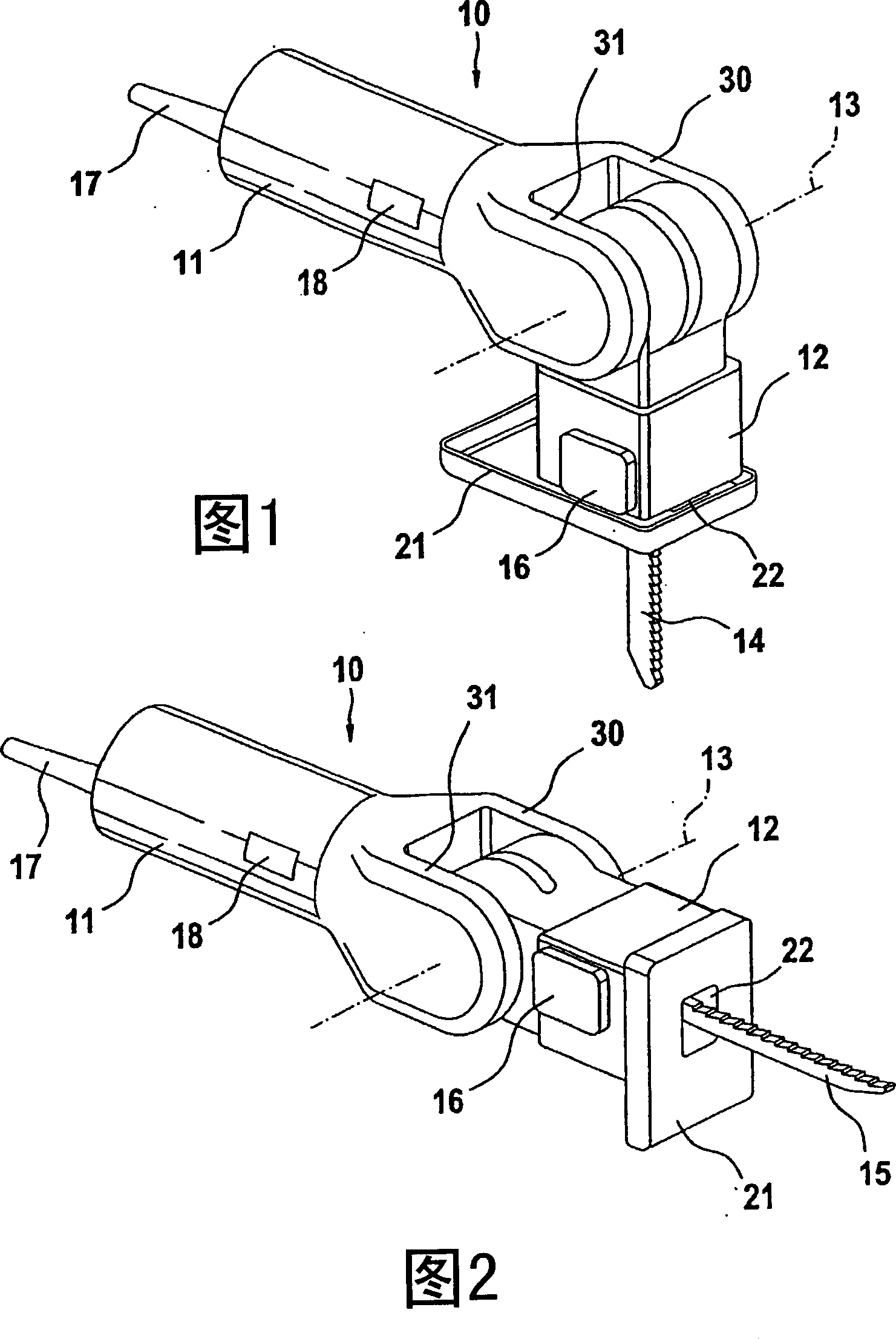

[0015] A universal saw 10 shown in FIGS. 1 and 2 has a housing consisting of essentially two housing parts (a partial housing 11 and a housing base 12 ). The partial housing 11 is adjustable in its angular position relative to the housing base body 12 about a bending axis 13 . 1 shows the universal saw in a position as a jigsaw jigsaw, in which the housing base 12 and the sub-housing 11 are at a 90° position to each other, a saw is guided in the housing base 12. The knife, here the knife is a commercially available saw blade 14 for jigsaws. Figure 2 shows the same universal saw in the straightened 180° position where it can be used as a saber saw. In this case of use, a commercially available saber saw blade 15 is inserted into the housing base body 12 .

[0016] In this case, by means of a clamping system for the saw blade, it is possible to use the saw blade 14 or 15 adapted to the respective sawing conditions, as a jigsaw for particularly fine work or as a saber saw for roug

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap