Modified eddy current probe having a faraday shield

a technology of faraday shield and eddy current probe, which is applied in the field of modified eddy current probes, can solve the problems of inaccurate distance measurement, inability of known sensors to monitor and analyze, and inability to measure the distance to low conductivity materials, etc., to achieve accurate monitoring, analysis, and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

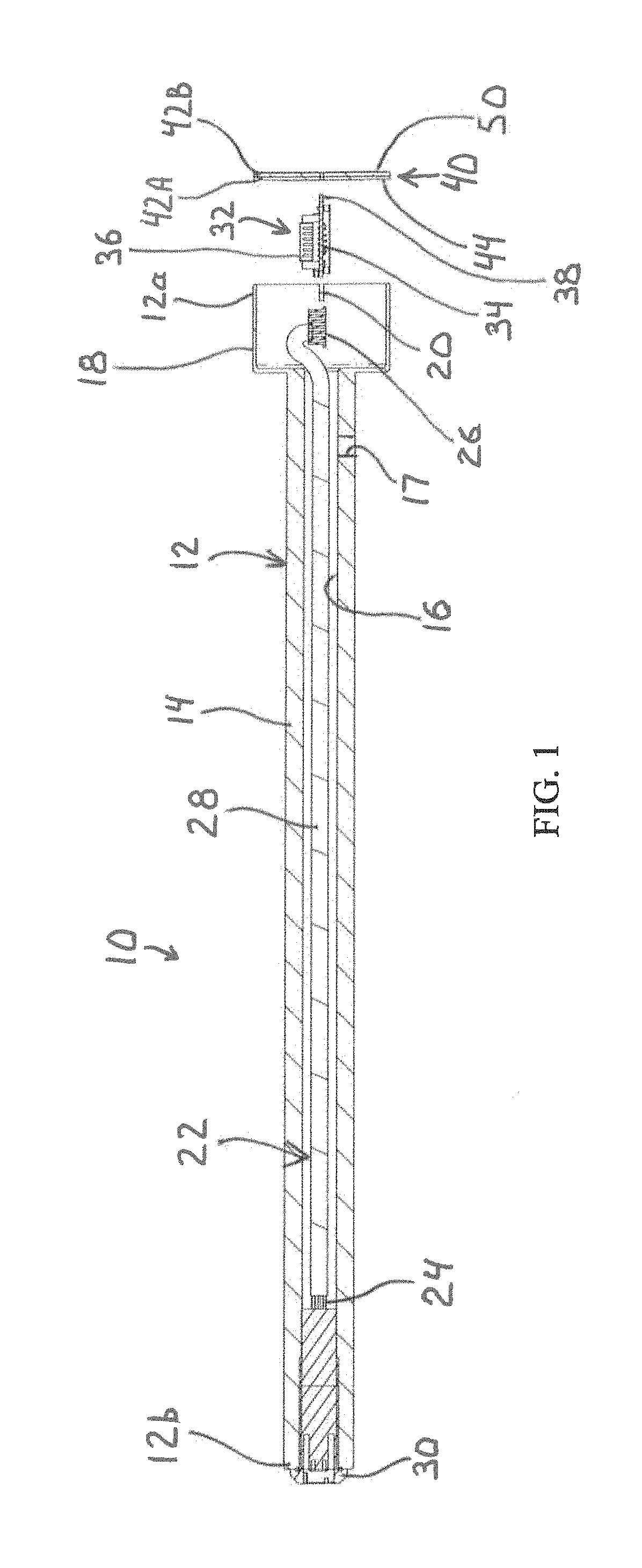

[0019]Referring now to the drawings, there is illustrated in FIG. 1 the structure of an improved or modified eddy current (MEC) probe 10 in accordance with this invention. The MEC probe 10 includes a probe body 12 having a first end 12a and a second end 12b. The probe body 12 has an elongated, substantially cylindrical stem 14 defining a longitudinally extending bore 16 formed therein. A hole 17, the purpose for which is described below, may be formed in the stem 14. The second end of the probe body 12 defines a cup 18. Longitudinally extending notches 20 are formed in a wall of the cup 18. The probe body 12 may be formed from brass. Alternatively, the probe body 12 may be formed from other metals, such as copper, metal alloys, and other conductive material.

[0020]In the illustrated embodiment, the stem 14 has an outside diameter of about 0.625 inches. Alternatively, the stem 14 may have any other desired diameter, such as a diameter within the range of about 0.50 inches to about 0.75 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap