Injector driving control apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

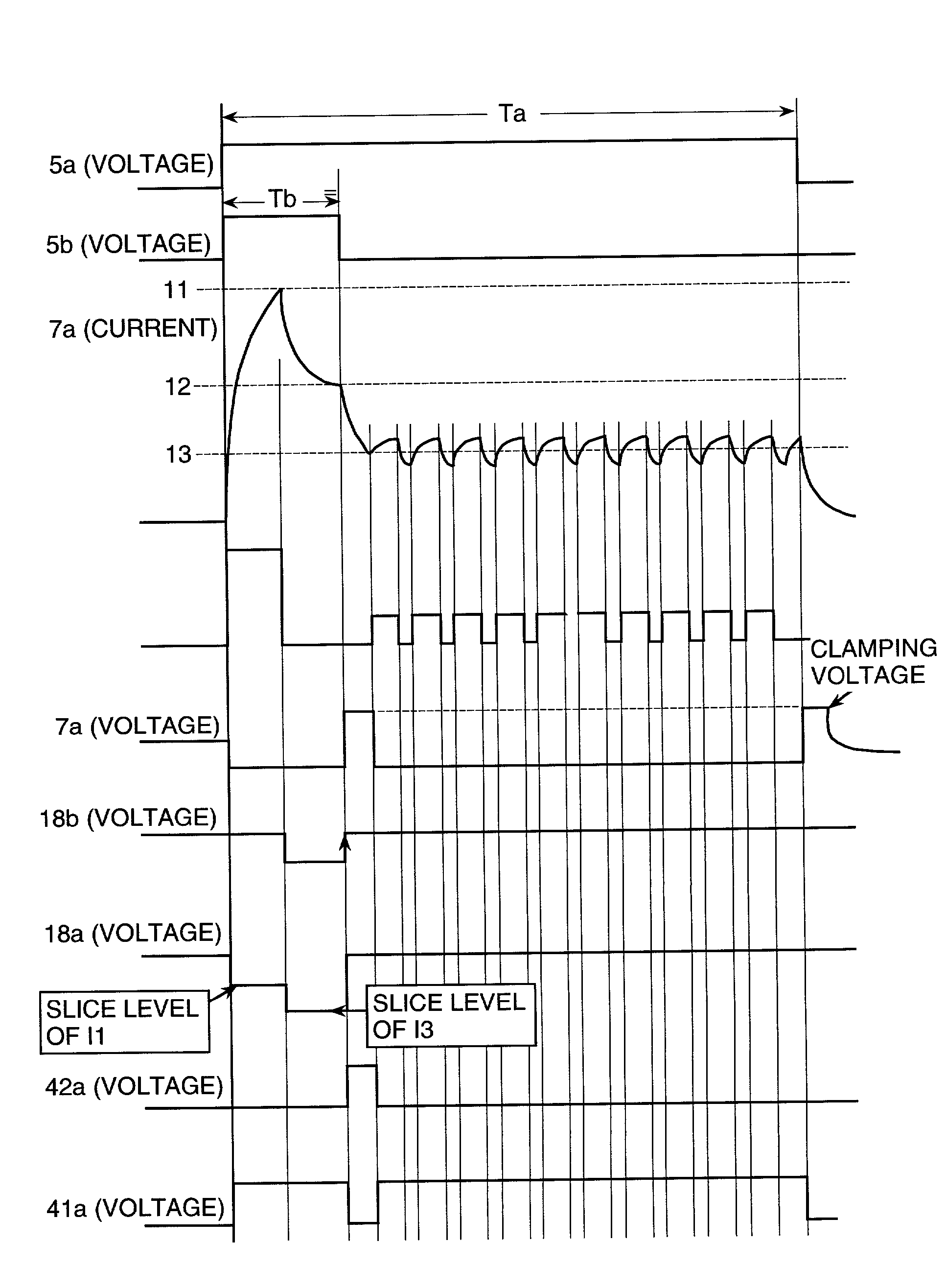

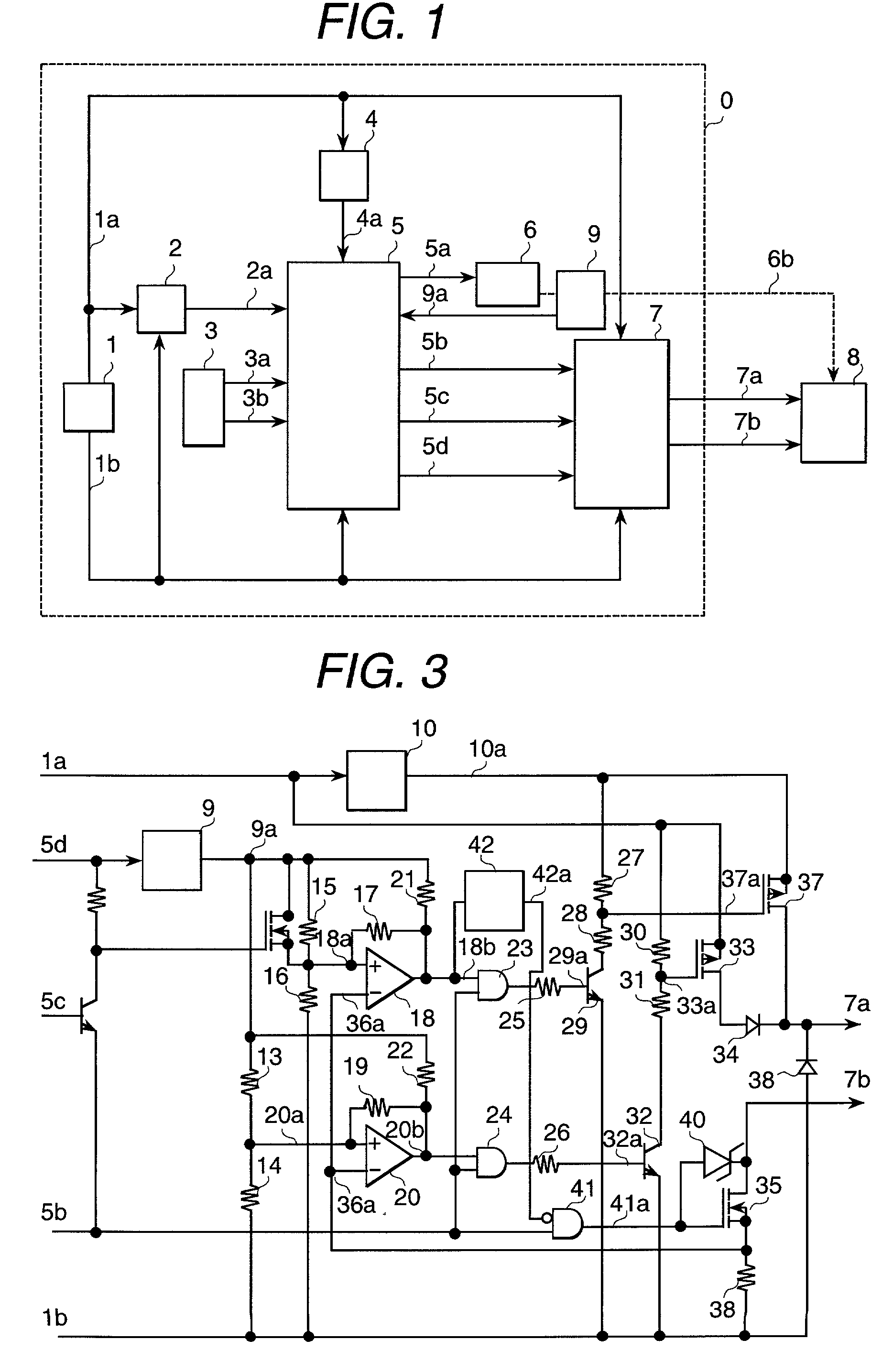

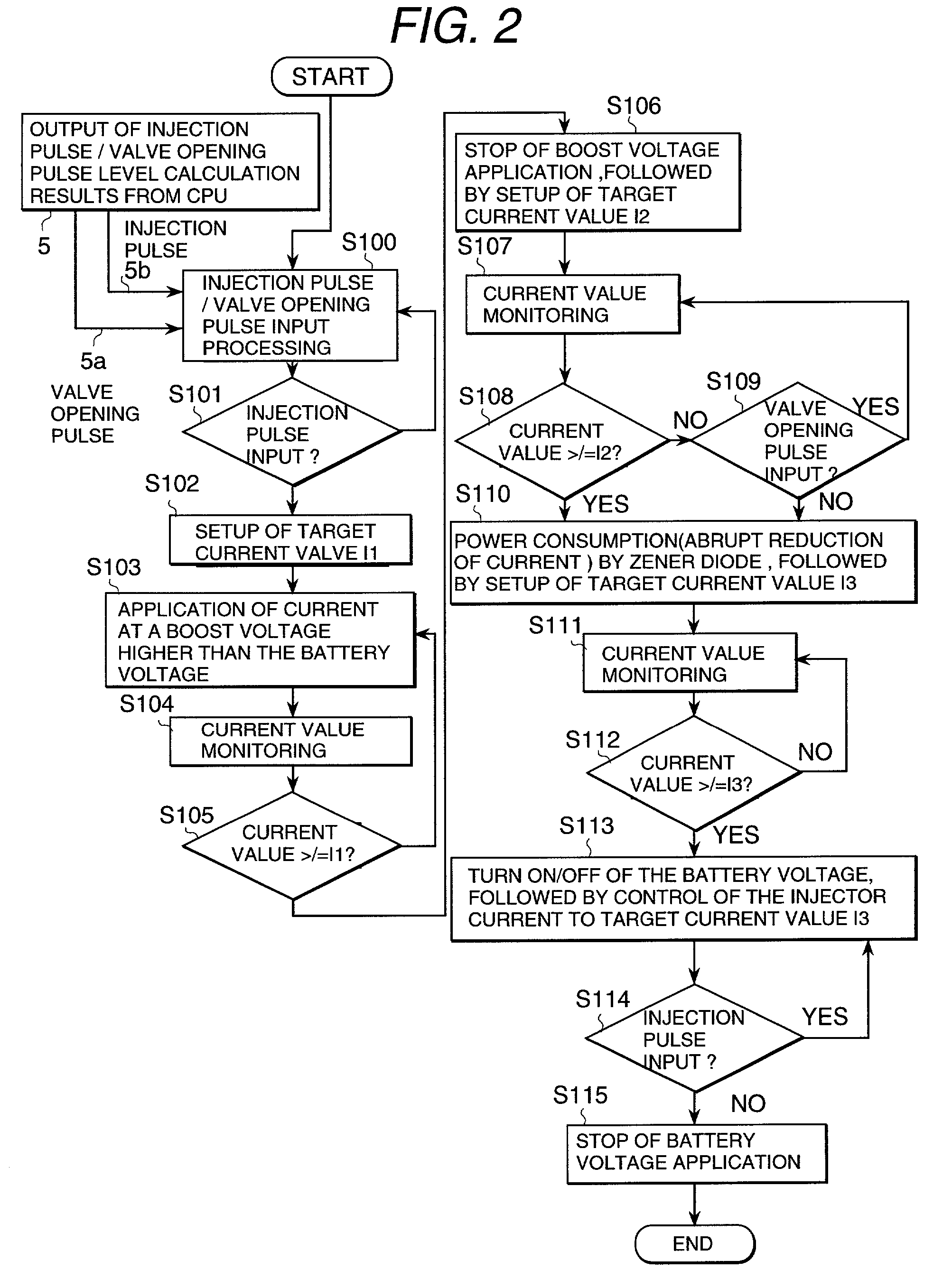

[0016] One embodiment of the injector driving control apparatus according to the present invention is described in detail below using drawings.

[0017] FIG. 1 is a block diagram for realizing the operation of the present invention.

[0018] Injector driving control apparatus 0 sends to a CPU 5 at least a reference position signal 3a, which indicates the piston position of an internal combustion engine that is detected by an internal combustion engine rotation detector 3, and an angle signal 3b, which indicates the rotational speed of the internal combustion engine. In CPU 5, a fuel pump 6 for supplying a fuel to the injector 8 is controlled by a fuel pump control signal 5a, and the pressure of the fuel to be supplied to injector 8 is detected by a fuel pressure sensor 9. The resulting signal is sent to CPU 5 as a fuel pressure signal 9a. Supply of power to injector driving control apparatus 0 is accomplished by supplying the voltage of a battery 1 as a battery power signal 1a, and after con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap