Rotary actuator for an adjuster of a vehicle seat

a technology of rotary actuator and vehicle seat, which is applied in the direction of gearing, mechanical control devices, instruments, etc., can solve the problem of significant reduction of subjective impression of a large actuating path with low efficiency, and achieve the effect of lowering transmission ratio and high transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

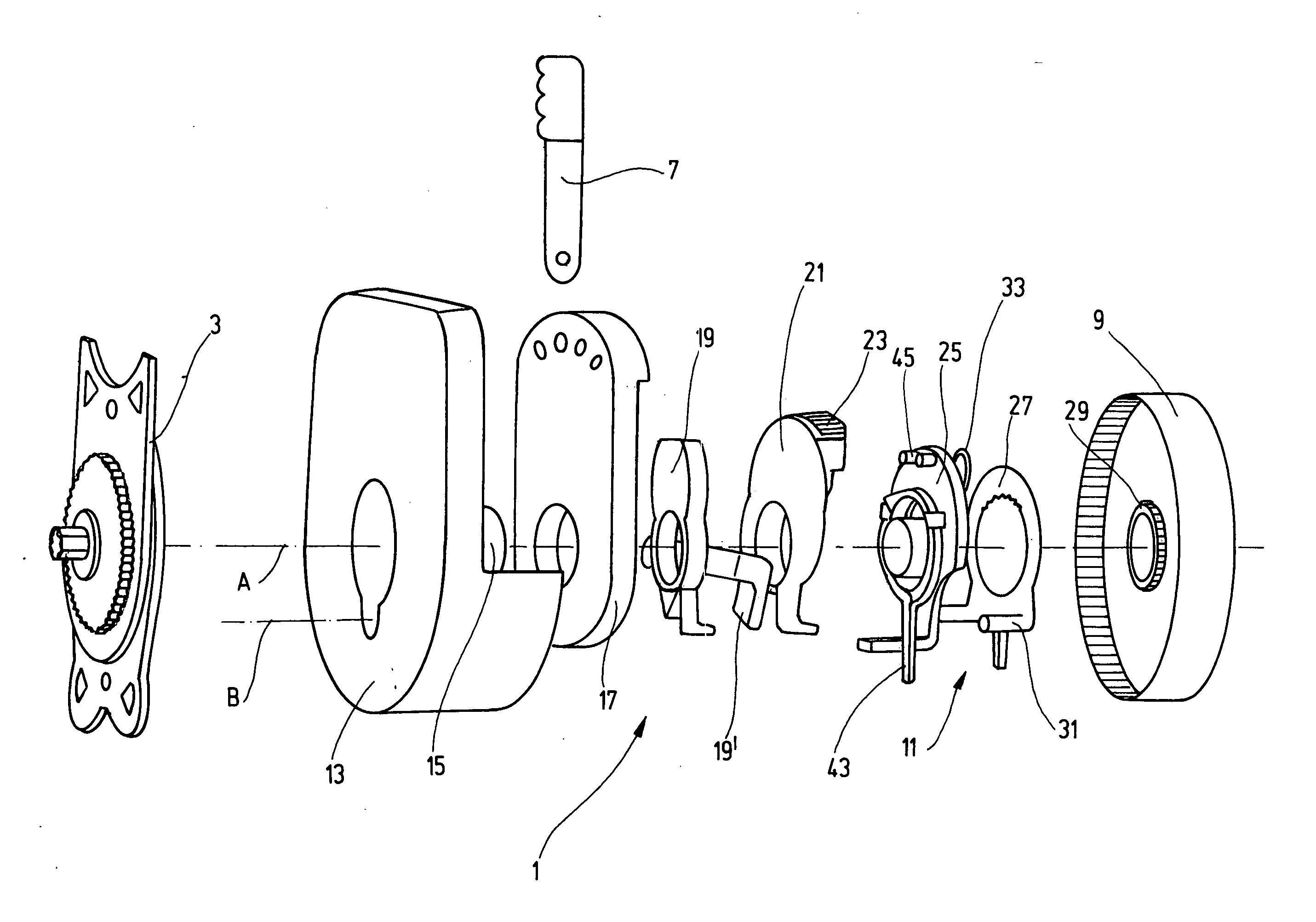

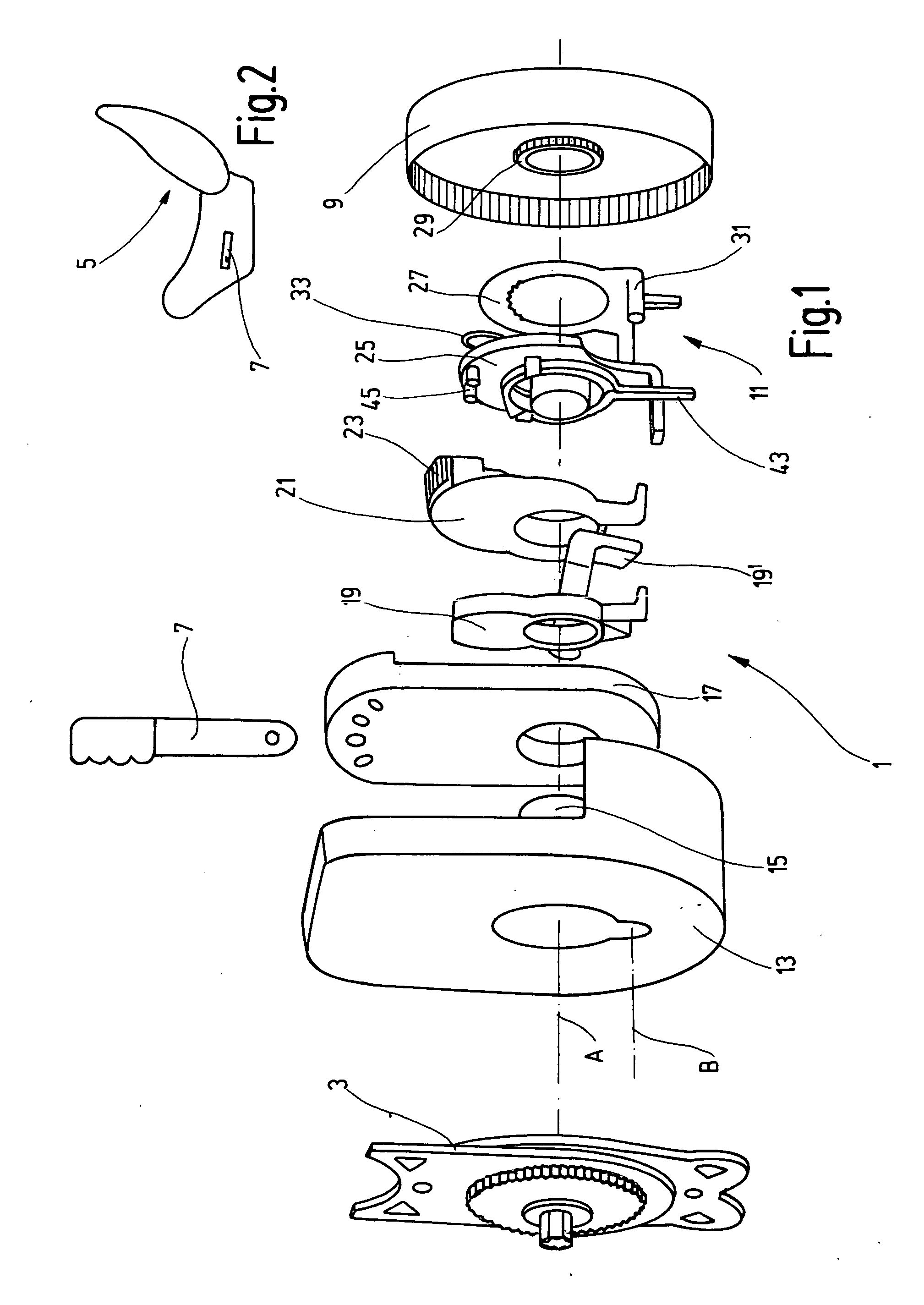

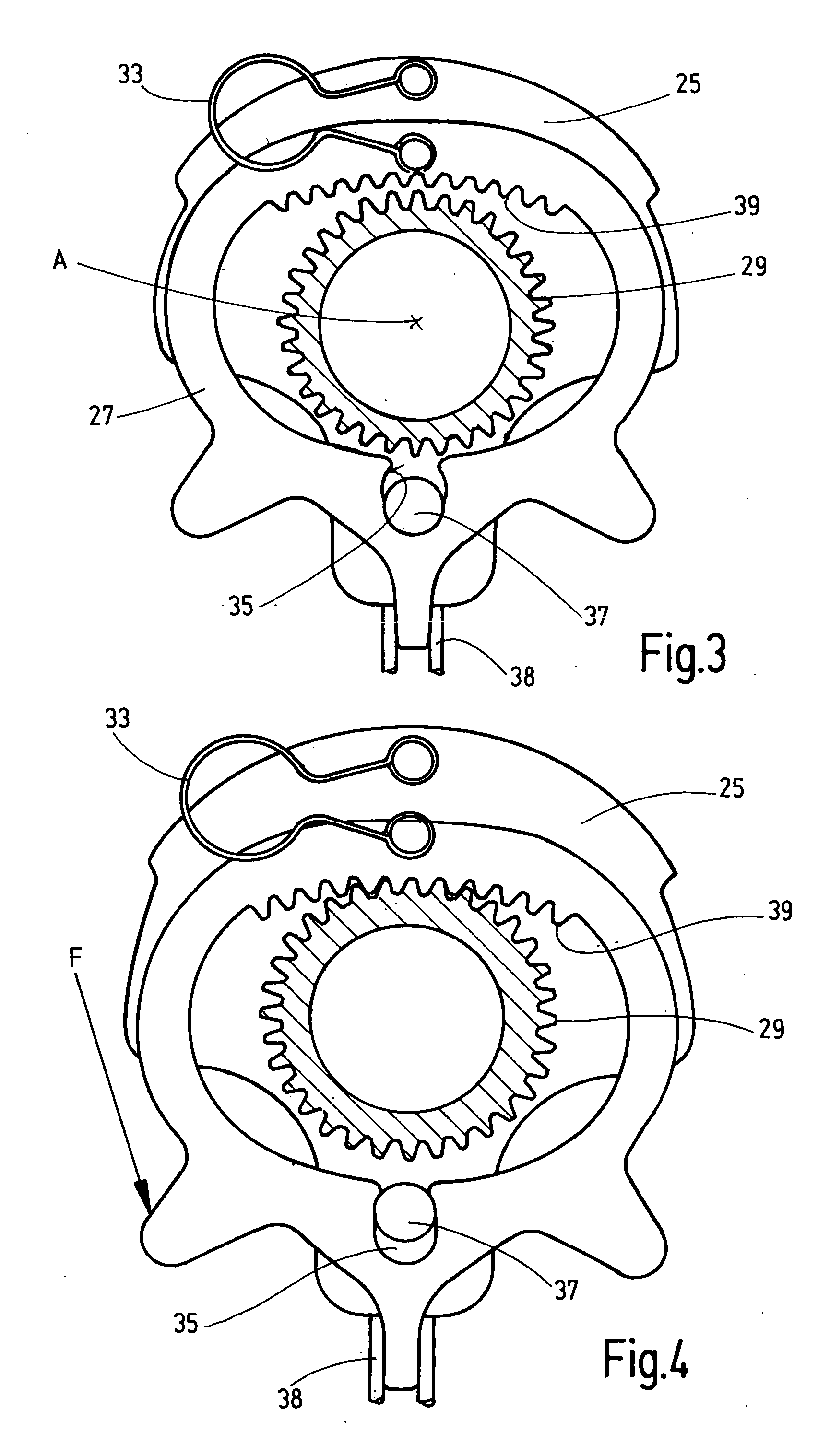

[0017] A manual rotary actuator 1, which is for actuating an adjuster 3 of a vehicle seat 5 in a motor vehicle, has a manually actuatable operating element 7 and an output element 9. In the present case, the operating element 7 is a hand lever. The output element 9 is in the form of a wheel that can be indirectly rotated in response to the operating element 7 being operated. The rotational movement of the output element 9 drives the adjuster 3. In accordance with the exemplary embodiment, the actuator 1 functions as a step-by-step mechanism for actuating a height adjuster. A transmission gearing 111 is arranged in the rotary actuator 1, operatively between the operating element 7 and the output element 9. In accordance with the invention, the transmission gearing 11 provides a high transmission ratio during an initial movement of the operating element 7 out of the inoperative position. This provision of the high transmission ratio during the initial movement of the operating element 7

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap