High efficiency light fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

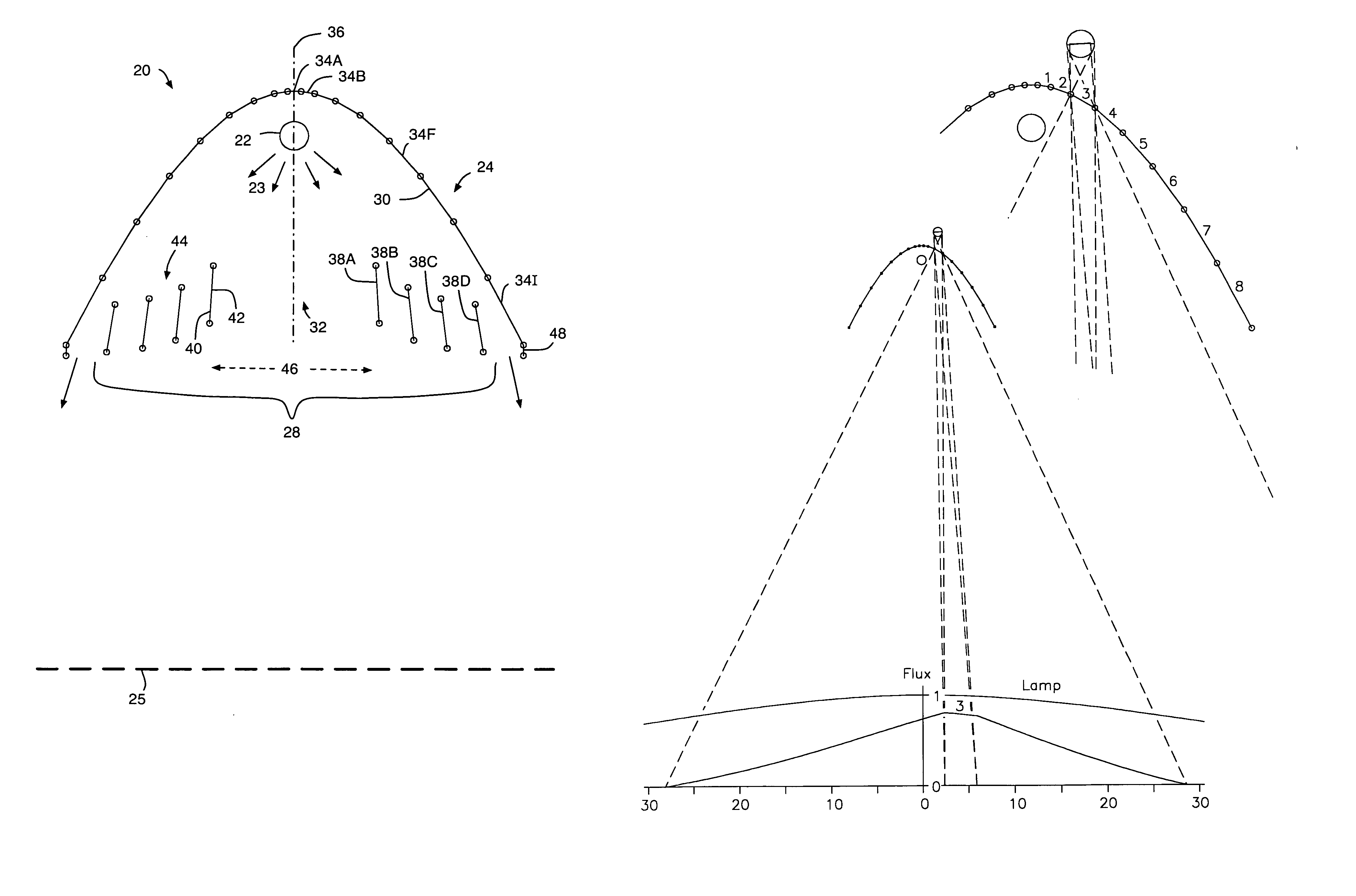

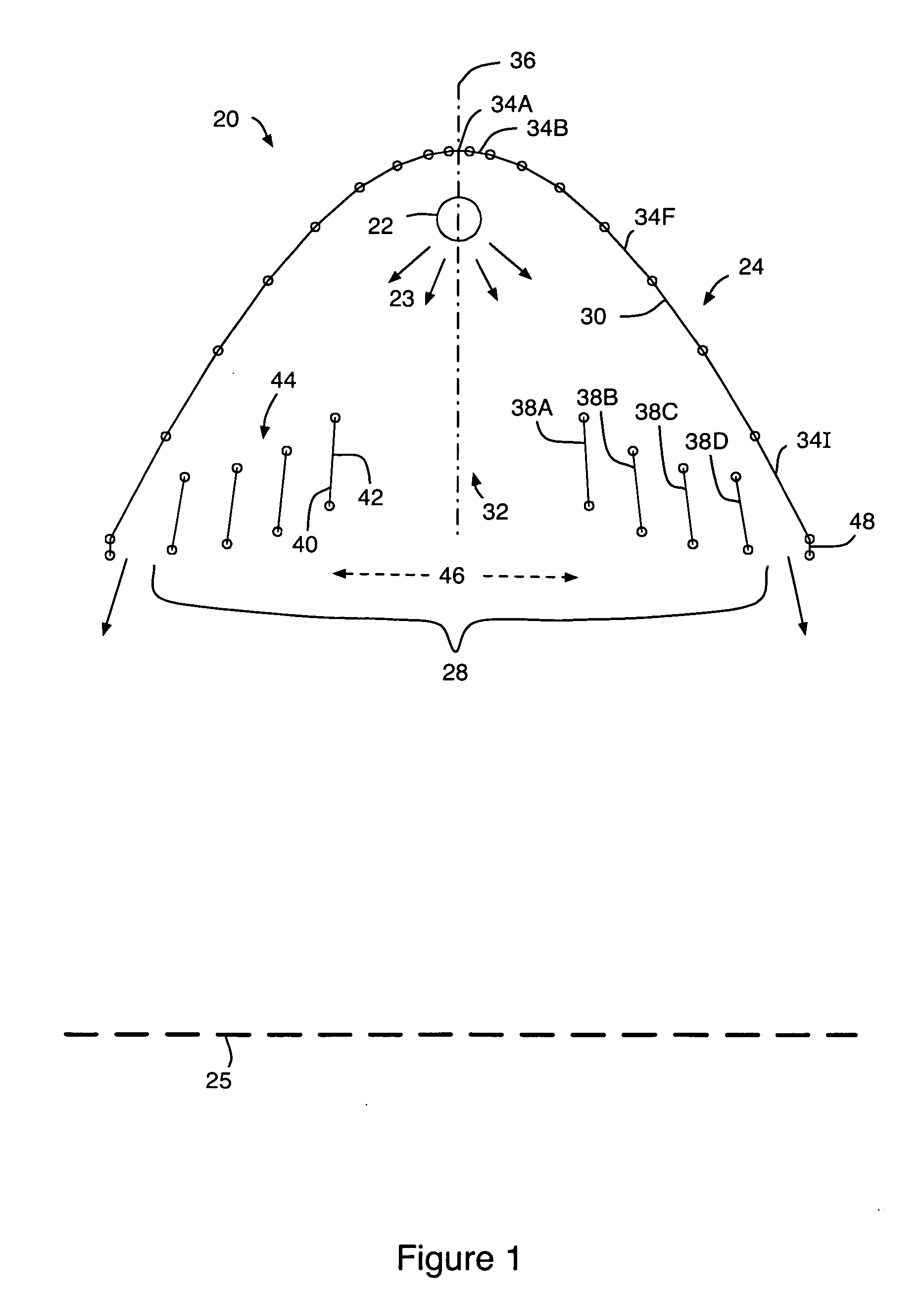

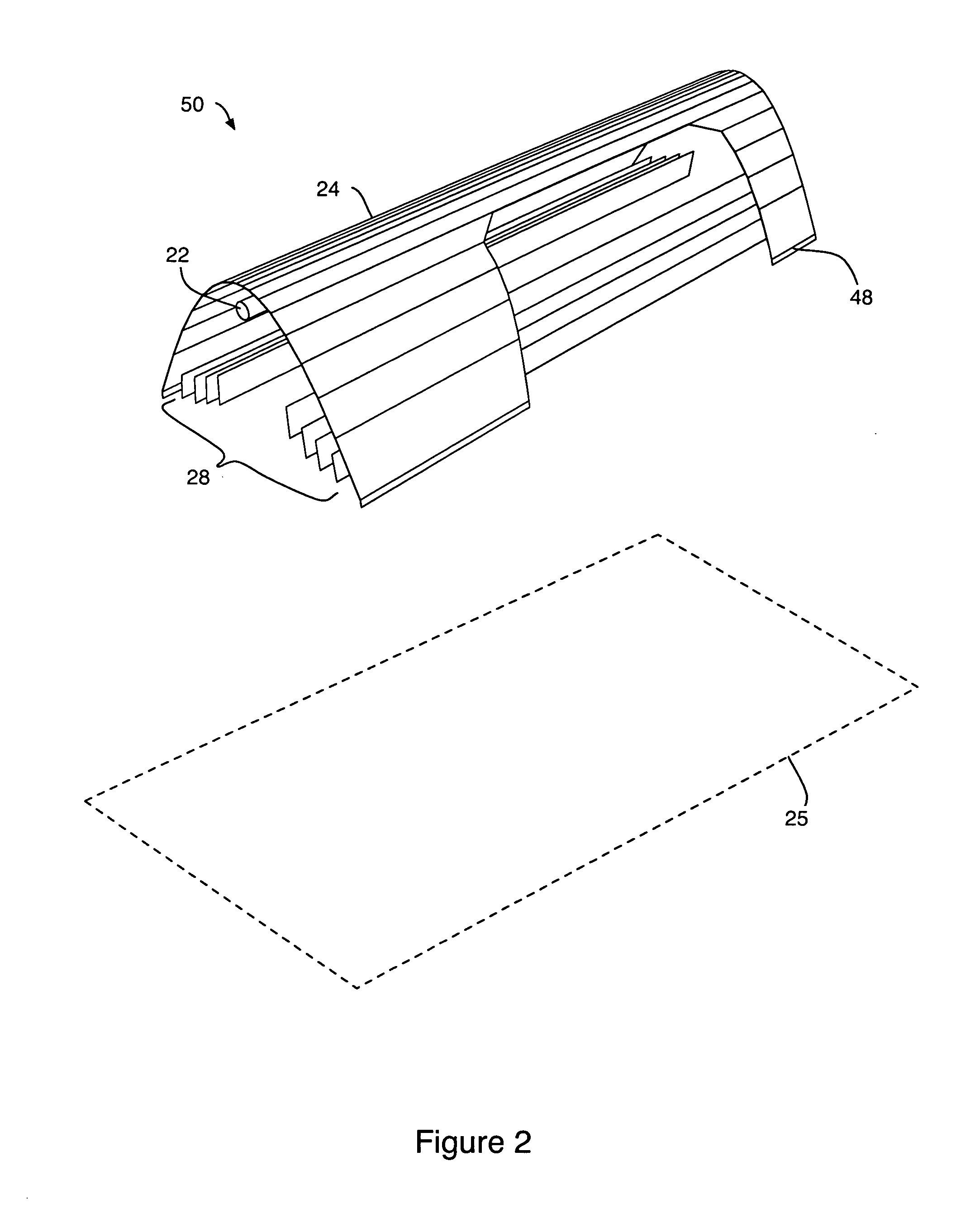

[0058] The present invention pertains to a high efficiency light fixture. One aspect of the invention relates to methods and apparatuses for directing a much greater percentage than attainable with prior art of the light generated therefrom within a specific target area. For example, the light fixture may include one or more reflectors for redirecting any light traveling away from the target area (e.g., stray light) back to the target area. In one embodiment, the light fixture includes an outer reflector for redirecting a first portion of the stray light to the target area and an inner reflector for redirecting the remaining portions of the stray light to the target area. In another embodiment, the light fixture includes one or more partitions for redirecting light end to end of the light fixture. Another aspect of the invention relates to methods and apparatuses for controlling the intensity and location of the light inside the specific target area. That is, the light made incident in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap