Power cord

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

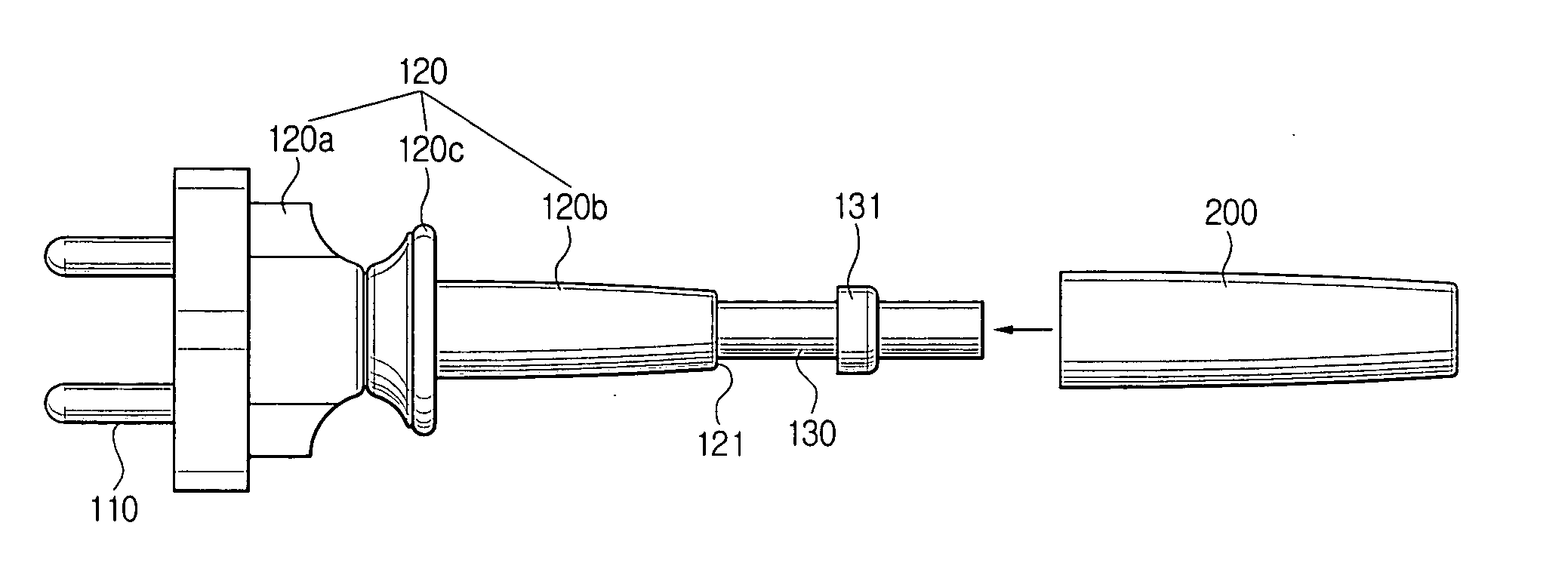

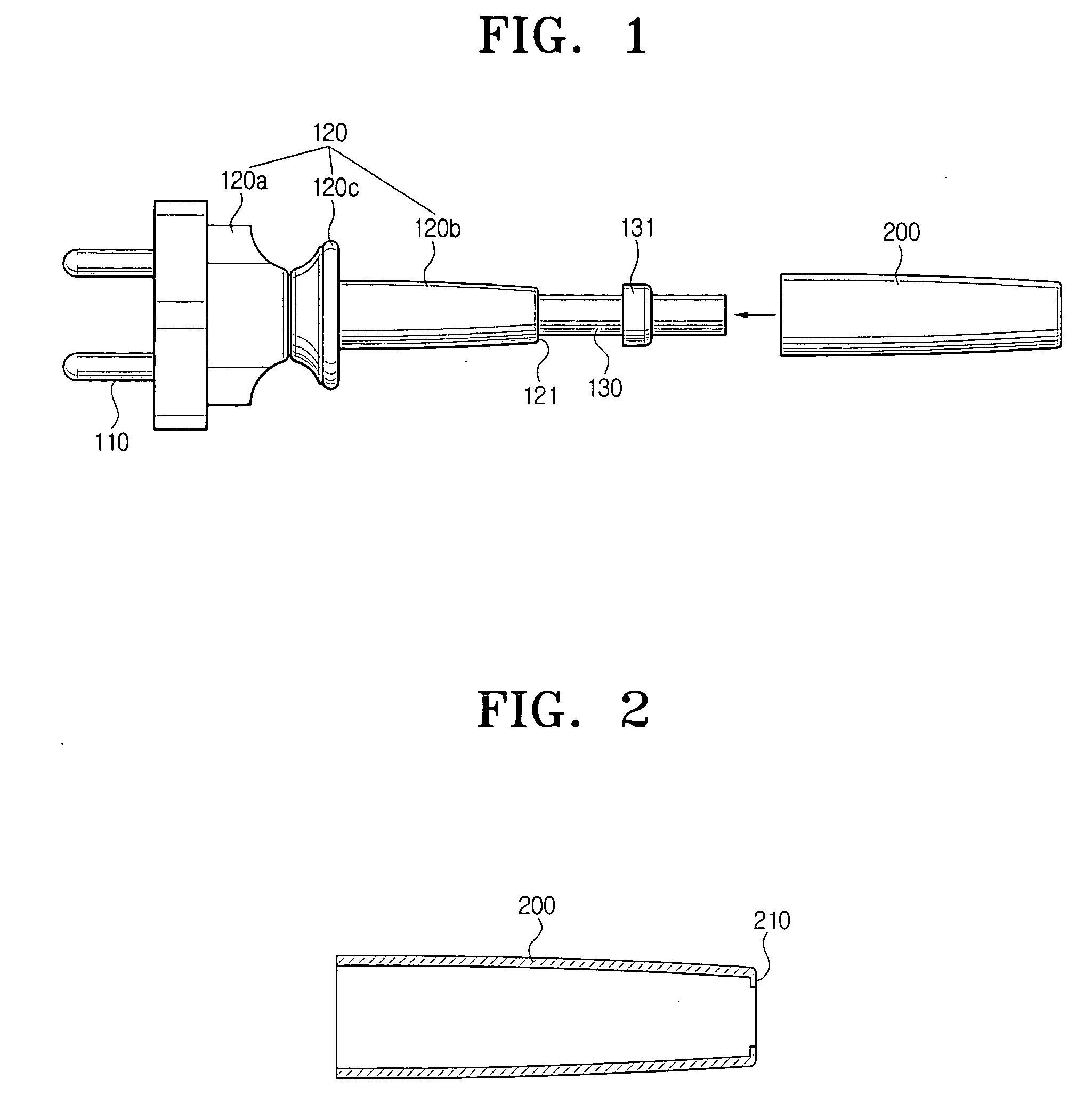

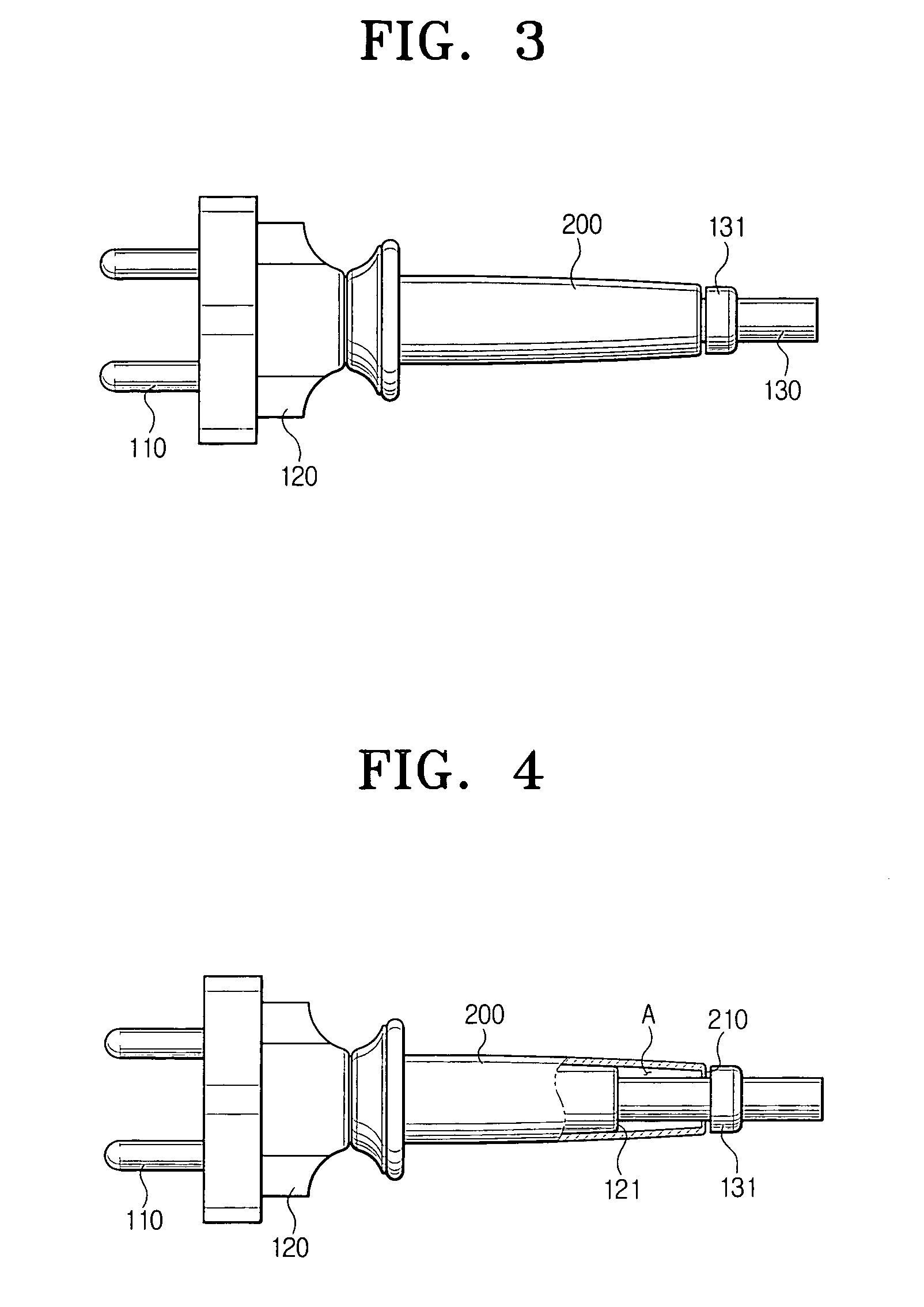

[0016] Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawing figures.

[0017] As shown in FIG. 1, the power cord includes at least one plug pin 110, a plug body 120, an electric wire 130, and a protecting tube 200. A supporting protrusion 120c and a movement regulating protrusion 131 for supporting the protecting tube 200 may be integrally formed at the plug body 120 and the electric wire 130 respectively. The electric wire 130 is an electric wire (now shown) covered with coating material and is a flexible stranded cable for user convenience.

[0018] The plug pin 110 is inserted in a wall outlet (not shown) and receives electricity. The plug body 120 includes a plug base 120a, a plug extended part 120b and the supporting protrusion 120c. The plug base 120a forms the body of the plug, and the plug pin 110 and the electric wire 130 are wired inside the plug base 120a. The plug extended part 120b extends from the plug base

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap