Method of developing a plan for replacing a product component using a scanning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

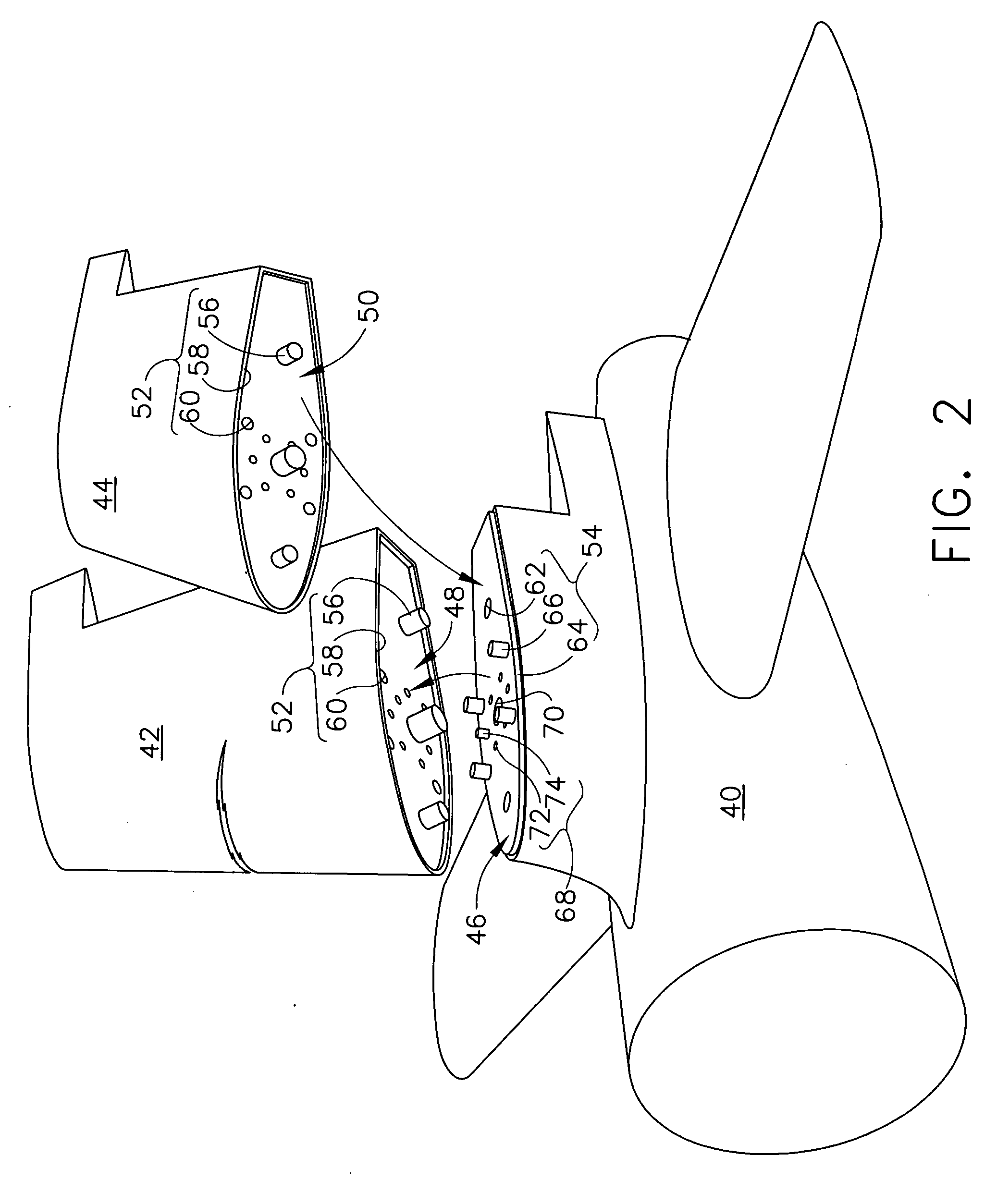

[0013] The present invention relates to a method of developing a plan for repairing a product and, more particularly, to a method of developing a plan for repairing a product using a scanning process to identify a preferred replacement part. Reference will now be made in detail to an implementation in accordance with methods, systems, and articles of manufacture consistent with the present invention as illustrated in the accompanying drawings. Methods, systems, and articles of manufacture consistent with the present invention allow accurate repair and manufacture of aircraft. Although use of the methods, systems, and articles of manufacture consistent with the present invention are primarily discussed with reference to aircraft, they may be applied to improve repair and manufacturing of other products (e.g., automobiles, tanks, ships, and other multi-component assemblies) without departing from the scope of the present invention.

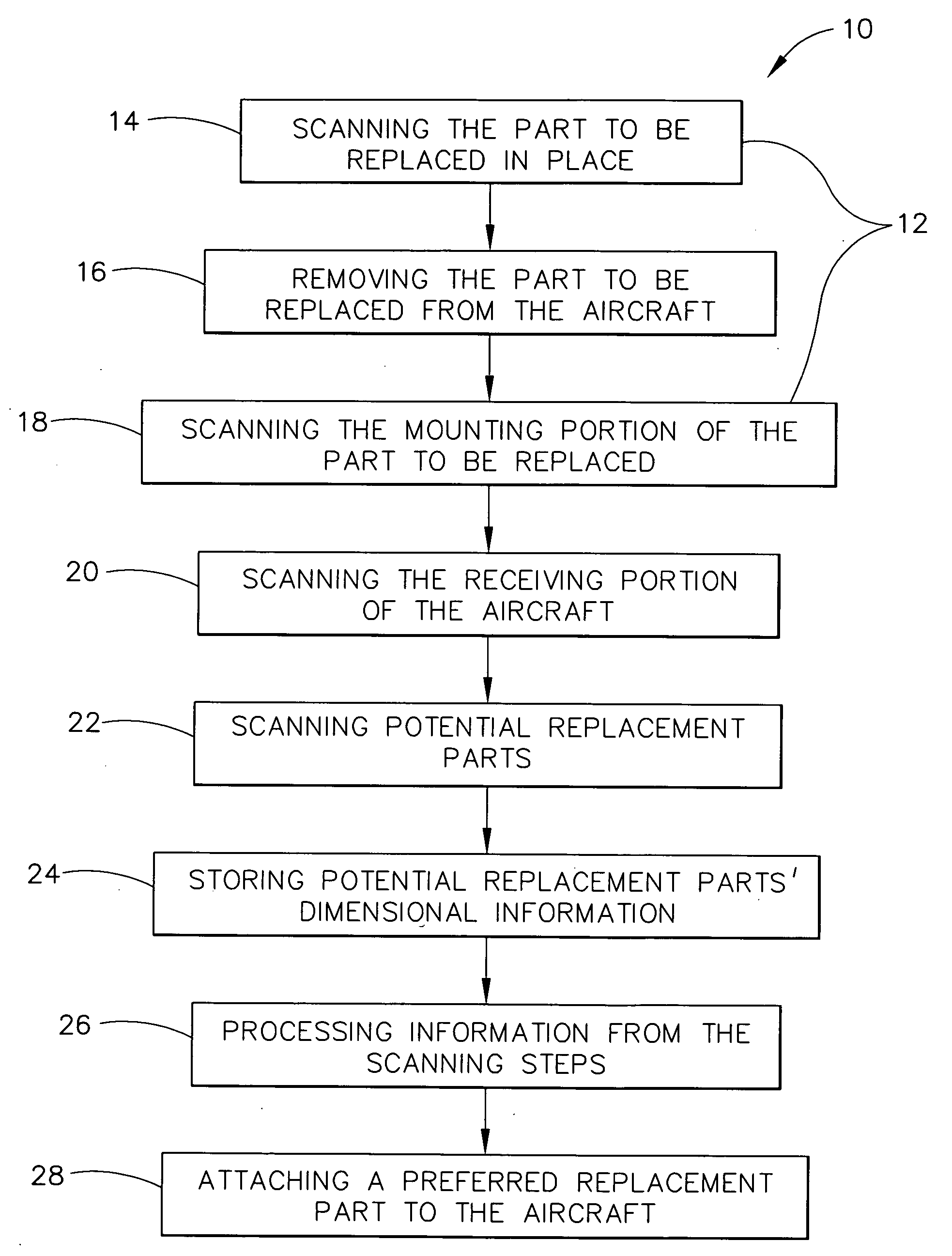

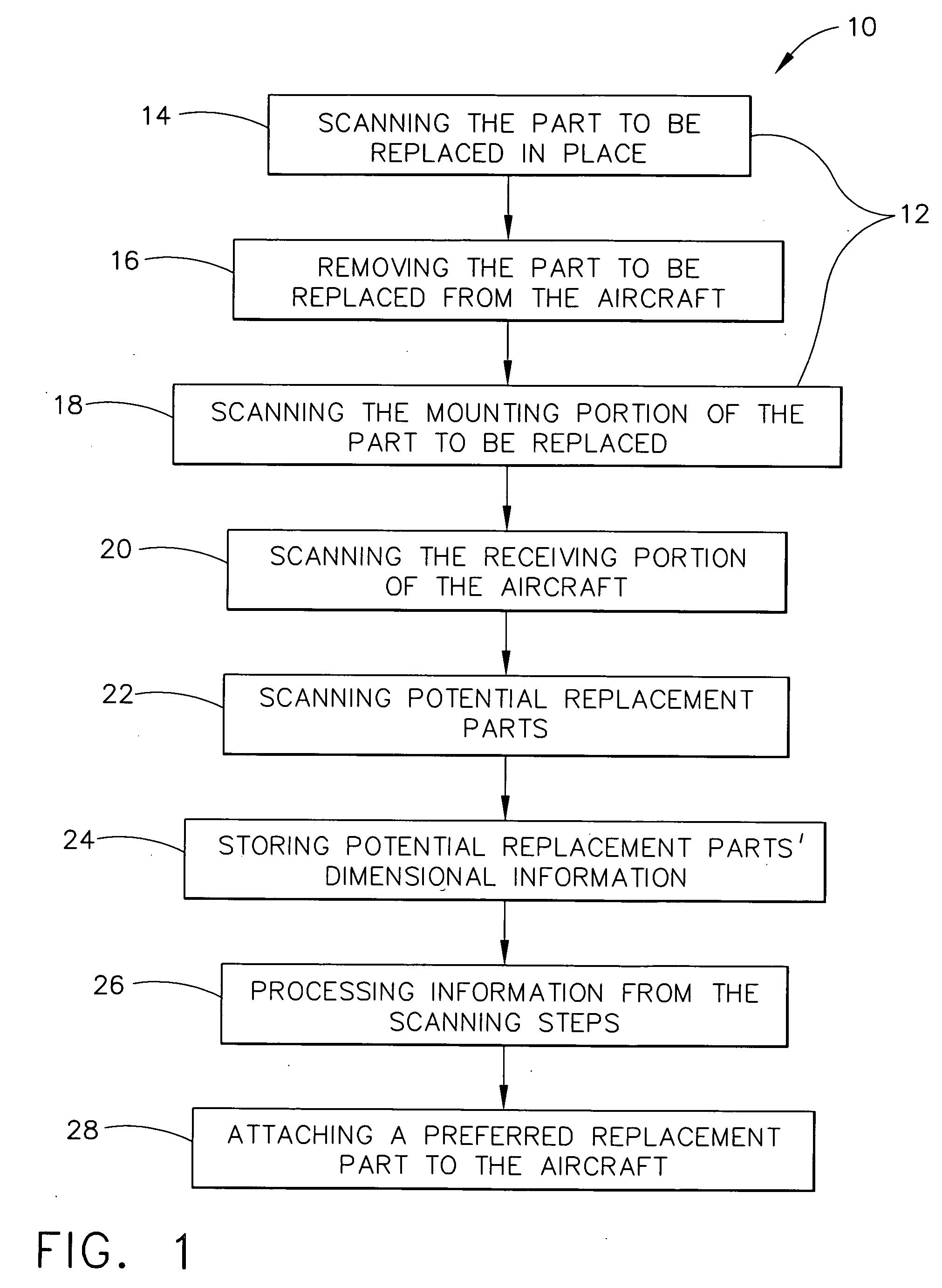

[0014] Referring now to the figures, and more particu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap