Driving system for matrix type backlight module

a backlight module and driving system technology, applied in the direction of instruments, static indicating devices, etc., can solve the problems of a large loss of entire light energy utilization rate, and a far inferior development of dynamic image and color of the crt television, so as to increase the quality of dynamic image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

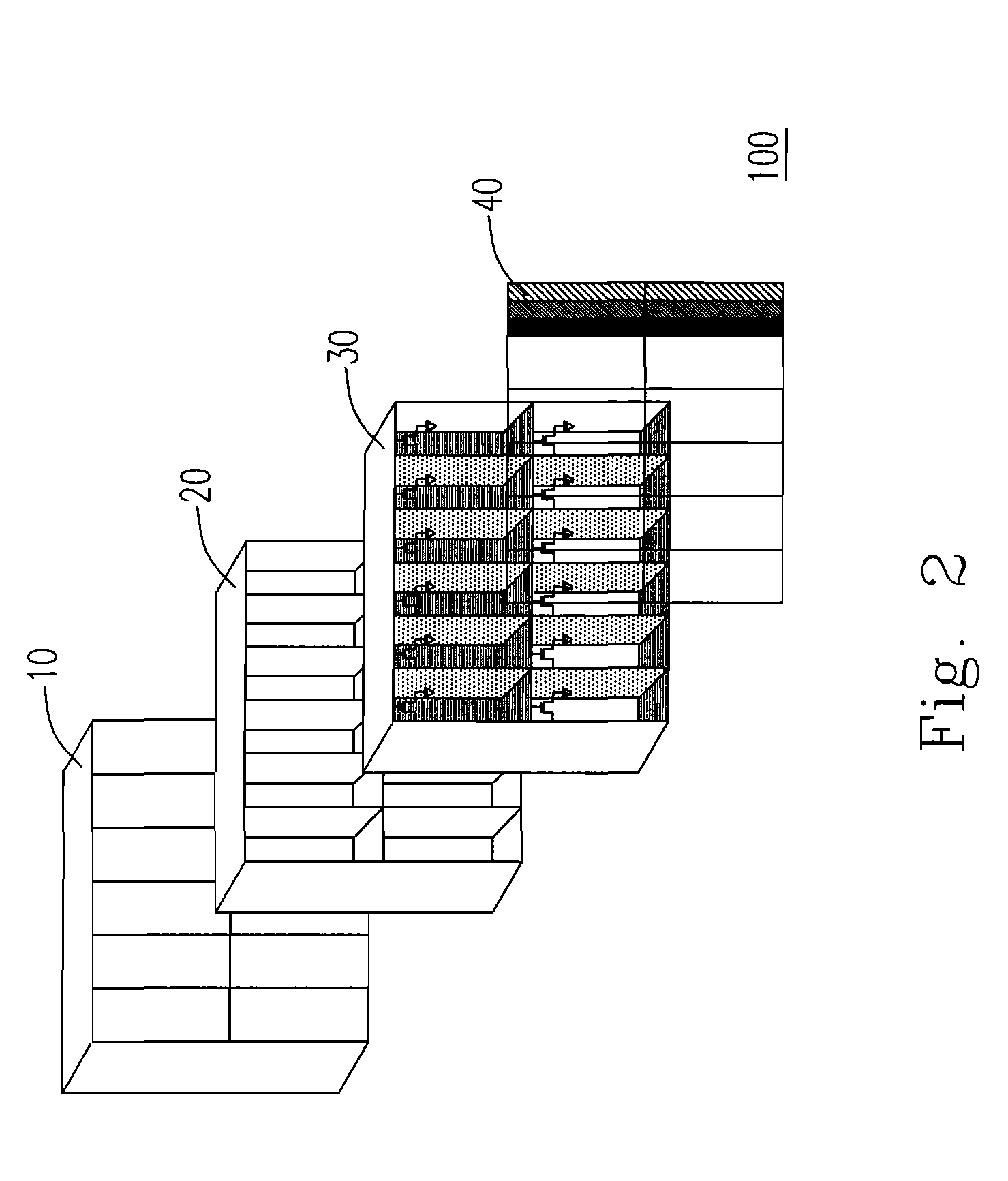

[0017] Please refer to FIG. 2, which is a schematic diagram showing the liquid crystal display device cooperating with the matrix type backlight module of the present invention. As shown in FIG. 2, the liquid crystal display device 100 comprises a matrix type backlight module 10 for forming a planar light source in which each of the plurality of light spots can be independently modulated. A black matrix layer 20 is disposed on top of the matrix type backlight module 10 to separate the light between the light spots in proximity. A thin film transistor (TFT) layer 30 is disposed on top of the black matrix layer 20 for forming each of the plurality of pixels for the liquid crystal display device. The number of pixels of the thin film transistor layer 30 can be the number of the light spots of the matrix type backlight module or its multiple, in order to make each of the plurality of light spots of the matrix type backlight module 10 corresponding to one or n of the pixels of the thin film

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap