Sample collector and components thereof

a sample collector and sample technology, applied in the field of sample collectors and components thereof, can solve the problems of insufficient sealing of all the joints of the system, wear on the tube, and high cost of electrical insulation protection, so as to reduce the movement of the peristaltic pump, reduce the flexing of the band, and reduce the cost of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

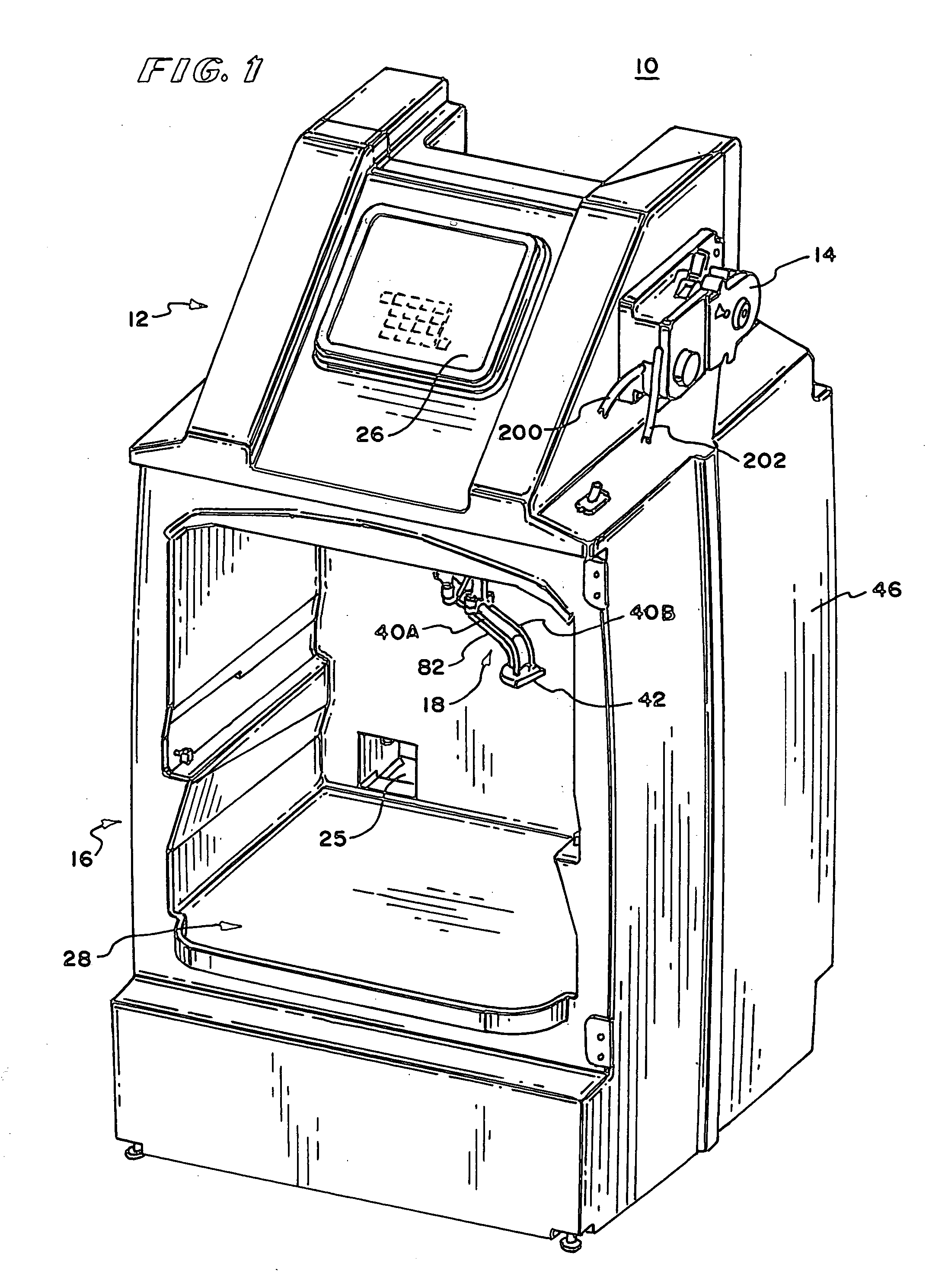

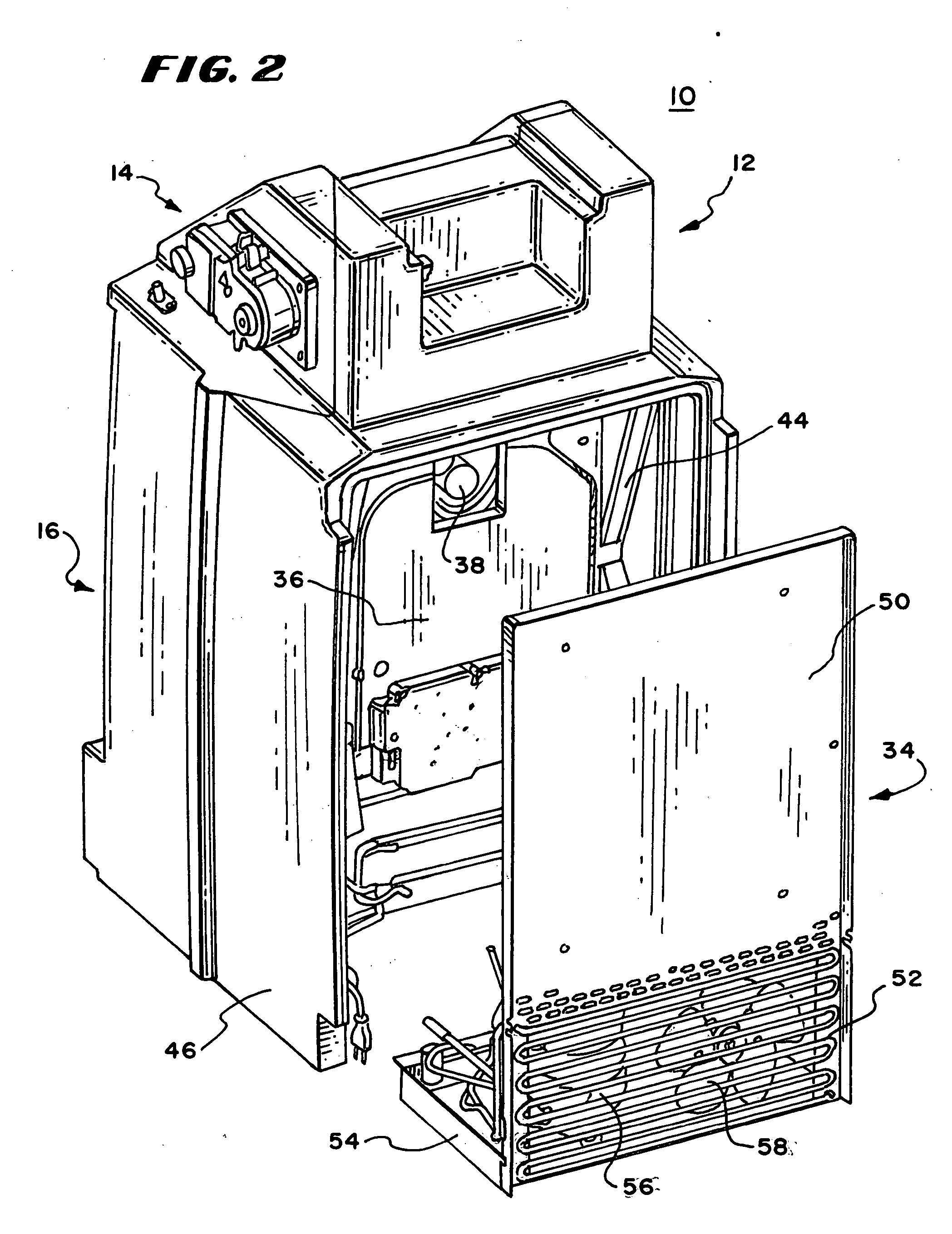

[0052] In FIG. 1, there is shown a simplified perspective view of a sample collector 10 which is one type of apparatus that may include inventions described hereinafter and which has as its principal component parts a control system 12, a peristaltic pump 14, and an enclosed refrigerated sample bottle compartment 16. The enclosed refrigeration system and sample bottle unit 16 is housed in an enclosure and has separately mounted above it the control system 12 to control the collection of samples in the refrigeration system and sample bottle unit 16 and a peristaltic pump 14 which, under the control of the control system 12, may pump liquid samples such as waste water samples into bottles included within the refrigeration system and sample bottle unit 16 (the bottle rack and bottles are not shown in this view for clarity).

[0053] The control system 12 includes a touch screen 26 for the control system 12. The peristaltic pump 14 is mounted to the side of the control system 12 and is contr

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap