Electric shaker conveyor assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

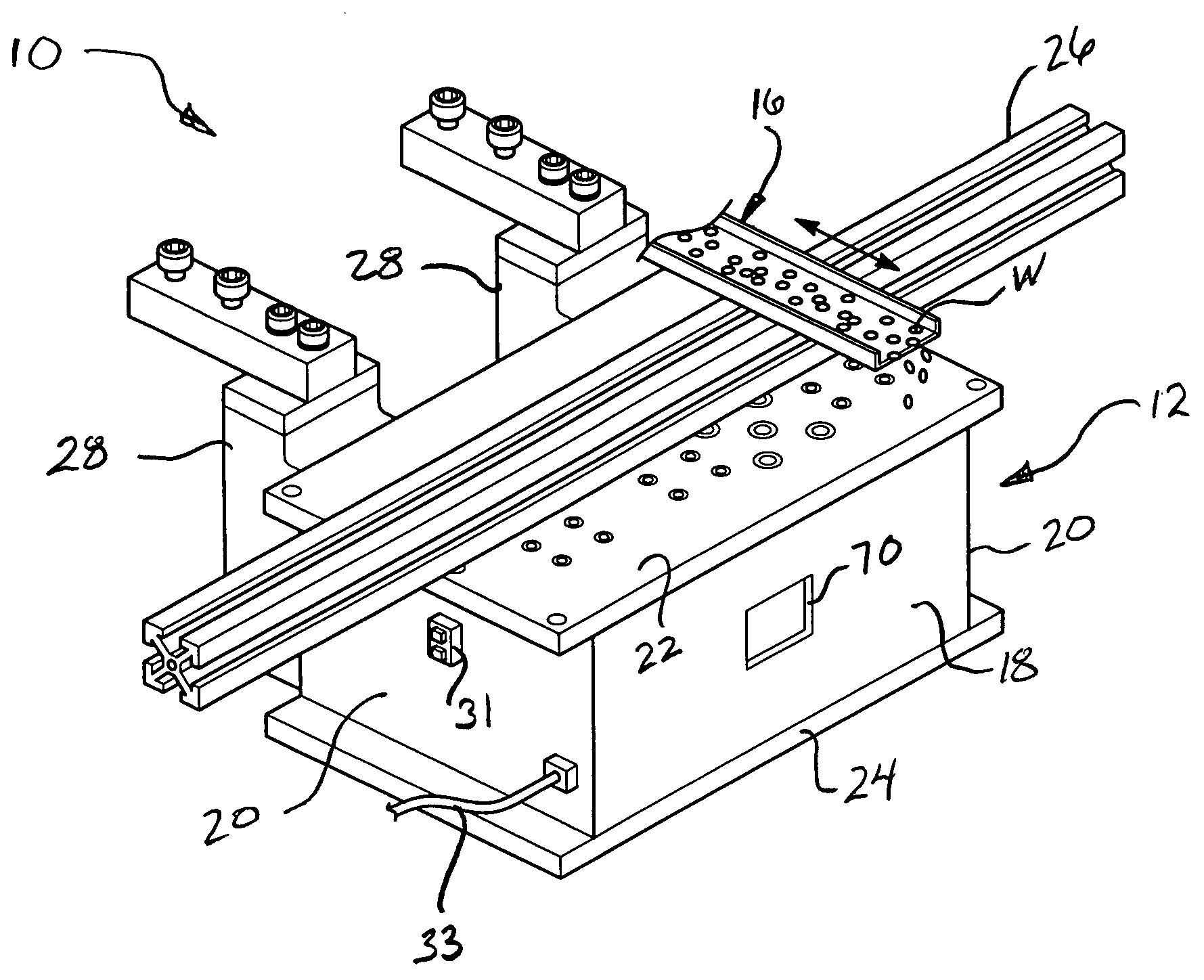

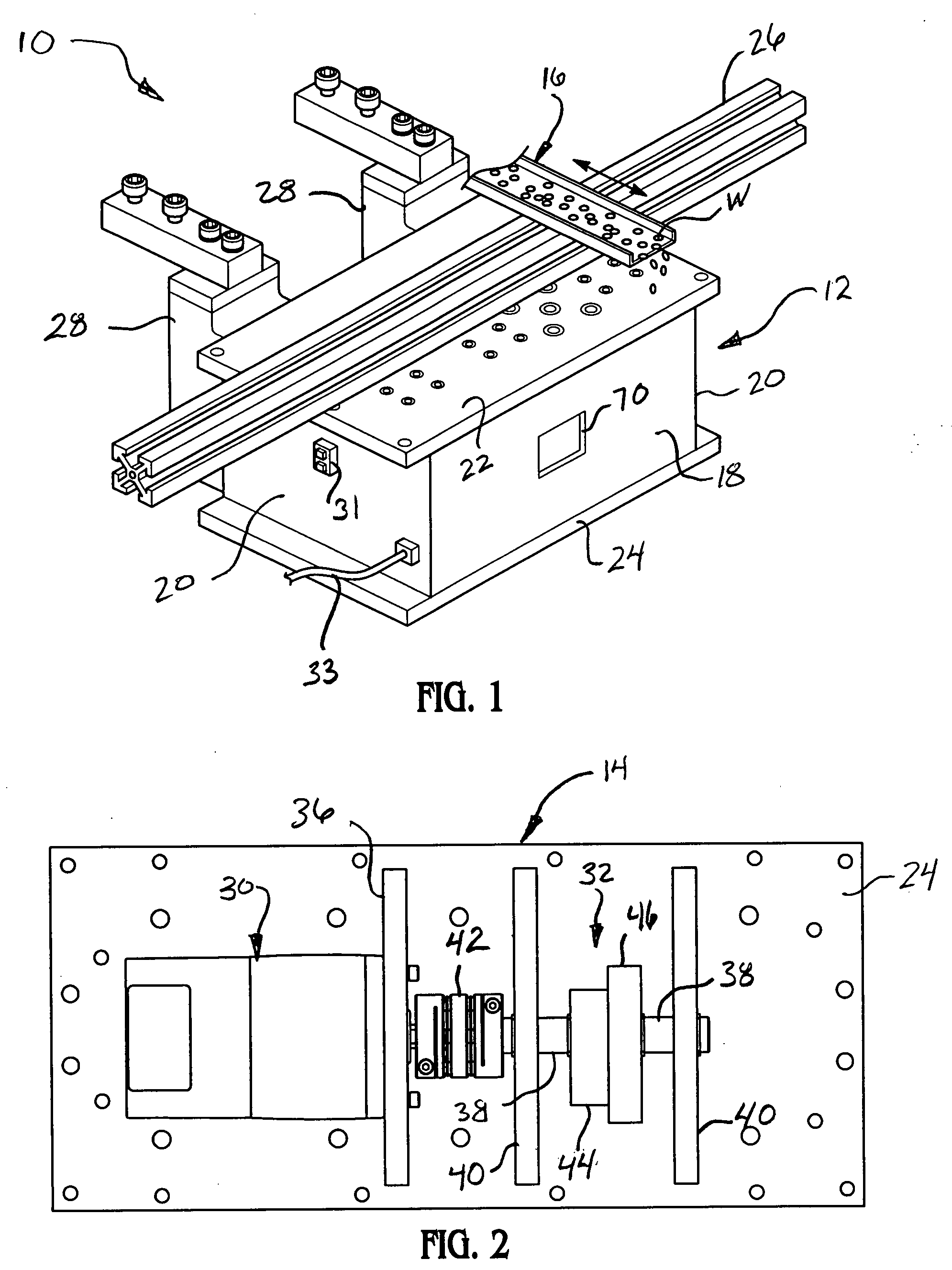

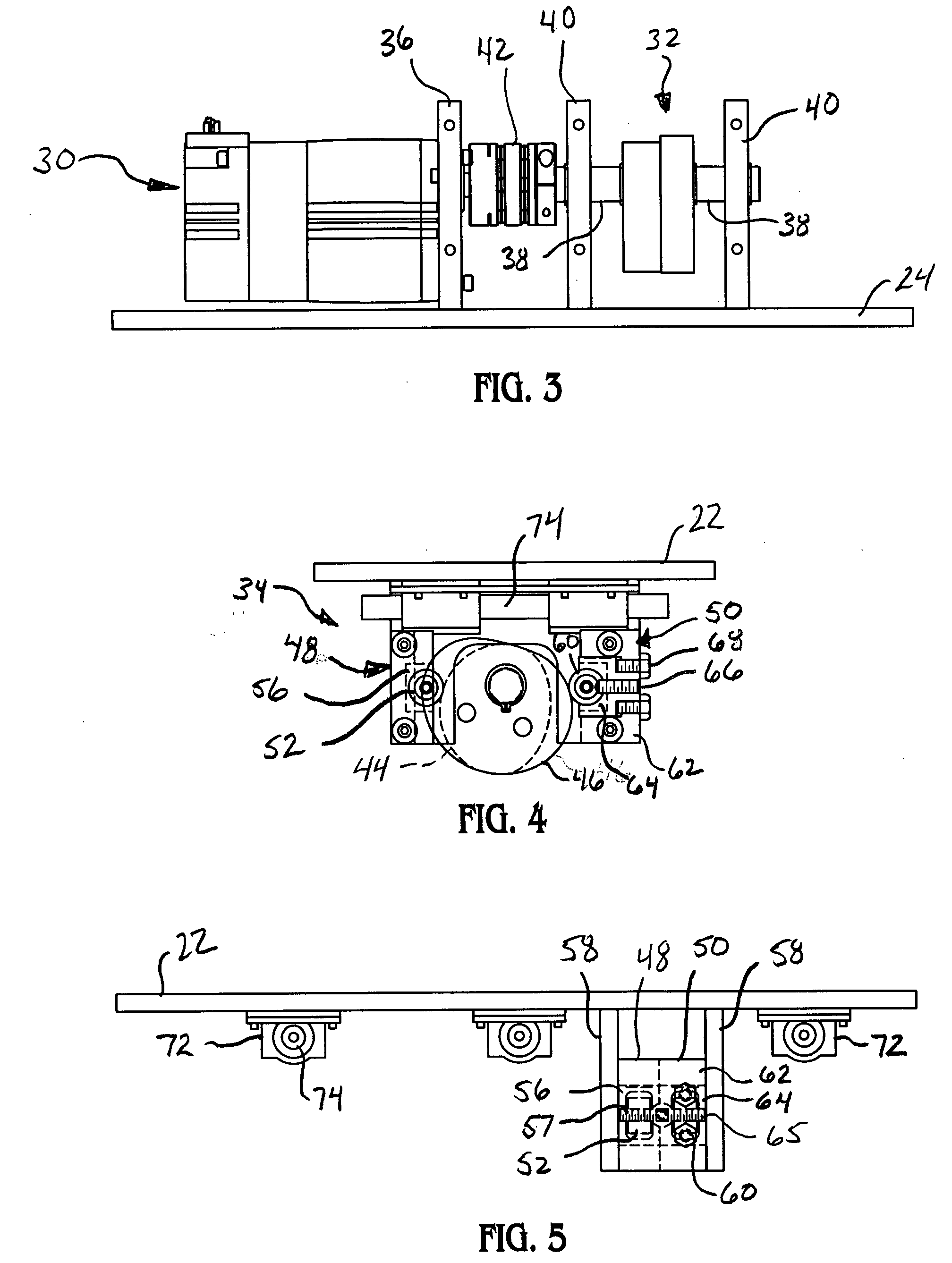

[0019]One embodiment of the shaker conveyor assembly of the present invention is generally indicated at 10 in FIGS. 1 through 5, where like numerals are used to designate like structure throughout the drawings. The shaker conveyor assembly 10 may be employed in any number of applications and neither the preceding discussion nor the description of the invention that follows should be interpreted as limiting the use of the invention.

[0020]Referring now to FIGS. 1 and 2, the conveyor assembly 10 of the present invention includes a housing, generally indicated at 12, and a drive system, generally indicated at 14, supported by the housing 12 (FIG. 2). At least one transport tray is generally indicated at 16. The transport tray 16 is supported by the housing 12 and is operatively connected to the drive system 14 as will be described in greater detail below. More specifically, the housing 12 may include a plurality of walls 18, 20 and a top plate 22. The housing 12 may further include a base

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap