Temperature compensation method for laser power of an optical disk drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

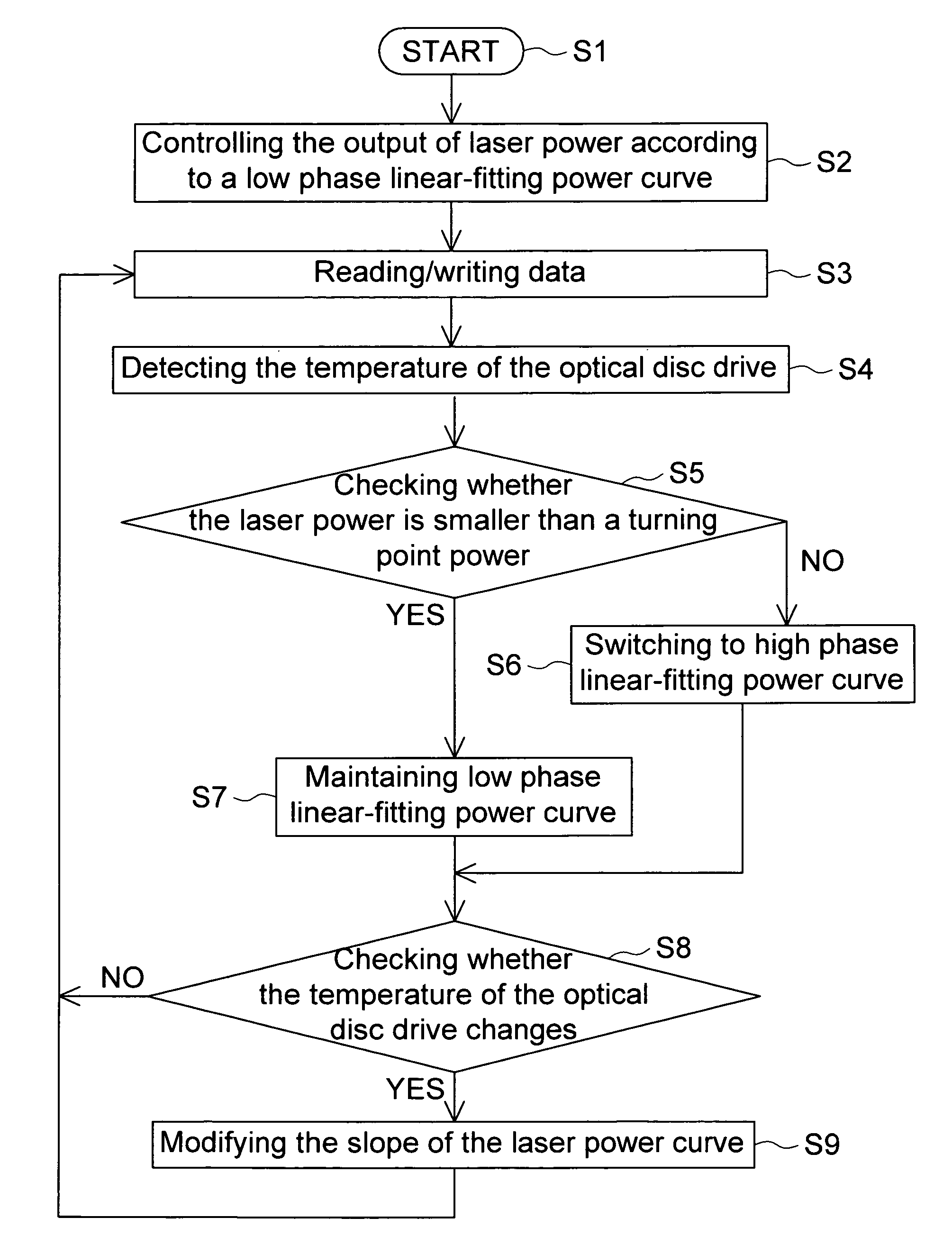

[0018]The technologies and methods used to achieve the above objects of the invention are exemplified in the following preferred embodiments with accompanying drawings.

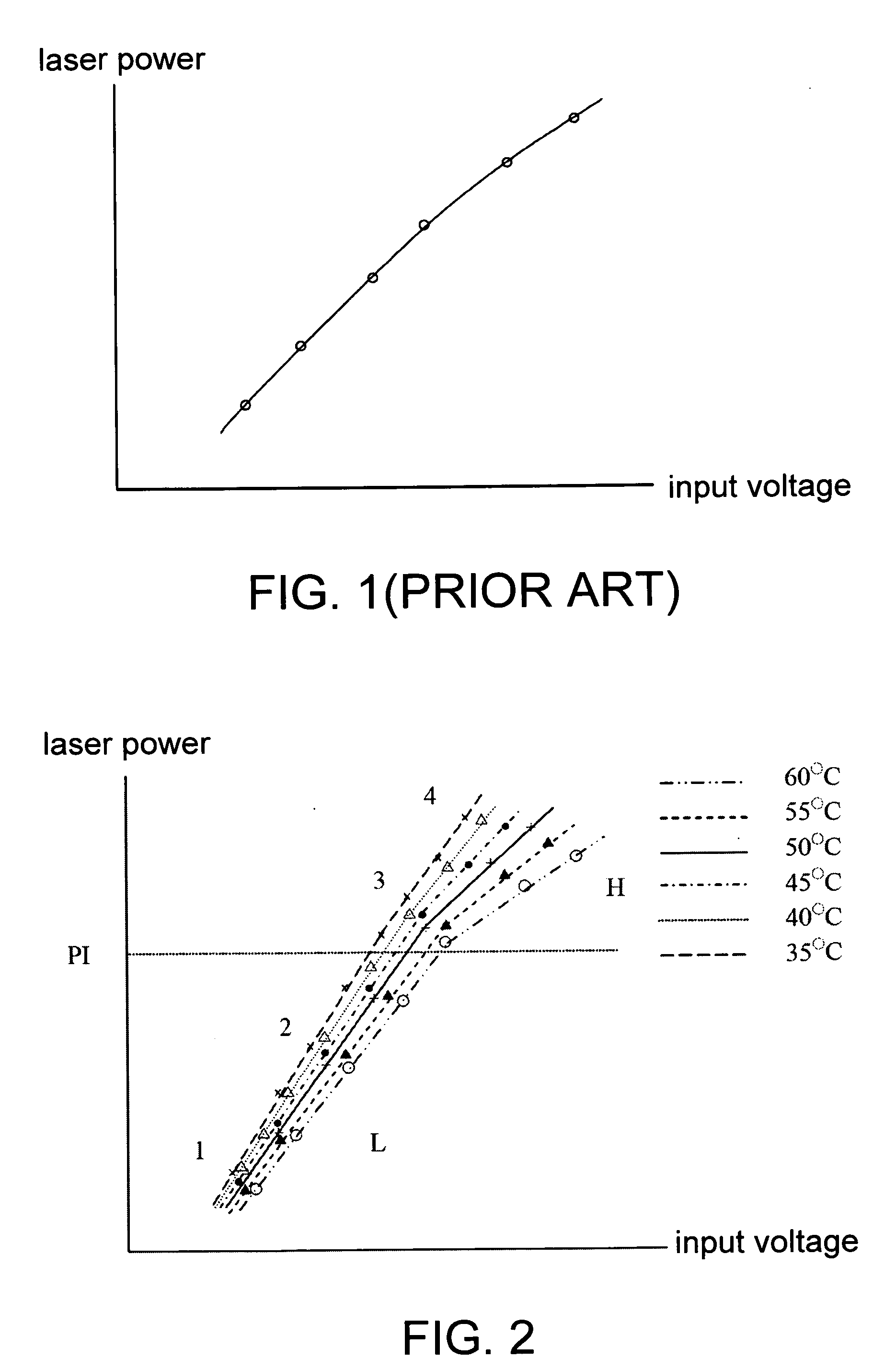

[0019]Referring to FIG. 2, a linear-fitting power curve of a temperature compensation method for laser power according to a preferred embodiment of the invention is shown. The invention obtains the optical disk drive linear-fitting power curve by use of practical measuring and curve fitting. Firstly, an optical disc drive is tested at different temperatures. In the present embodiment of the invention, the temperatures 35° C., 40° C., 45° C., 50° C., 55° C., and 60° C. are used as examples. When the optical disk drive is controlled to operate at a particular temperature and a plurality of different voltages (or currents) are respectively inputted to the laser diode, an output of laser power corresponding to each input voltage is detected and the testing result is recorded, and several test points are formed on the coordin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap