CO sensor online calibration method of battery thermal runaway monitoring system

A monitoring system and calibration method technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of sensor dynamic calibration limitations, cannot meet the high precision requirements of sensors, and poor real-time performance, so as to improve accuracy and real-time performance, Achieve online precise calibration and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

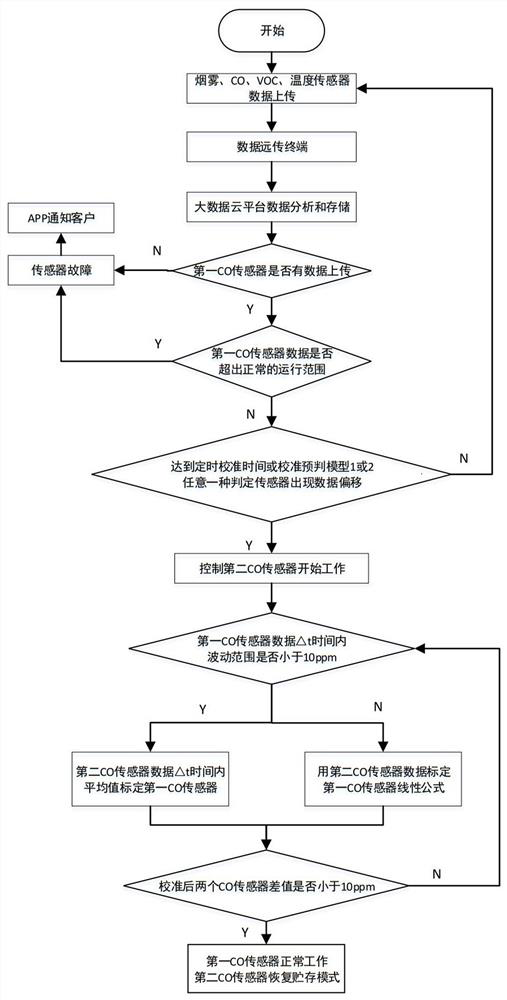

[0026]The technical scheme of the present invention will be described in detail below in conjunction with the drawings:

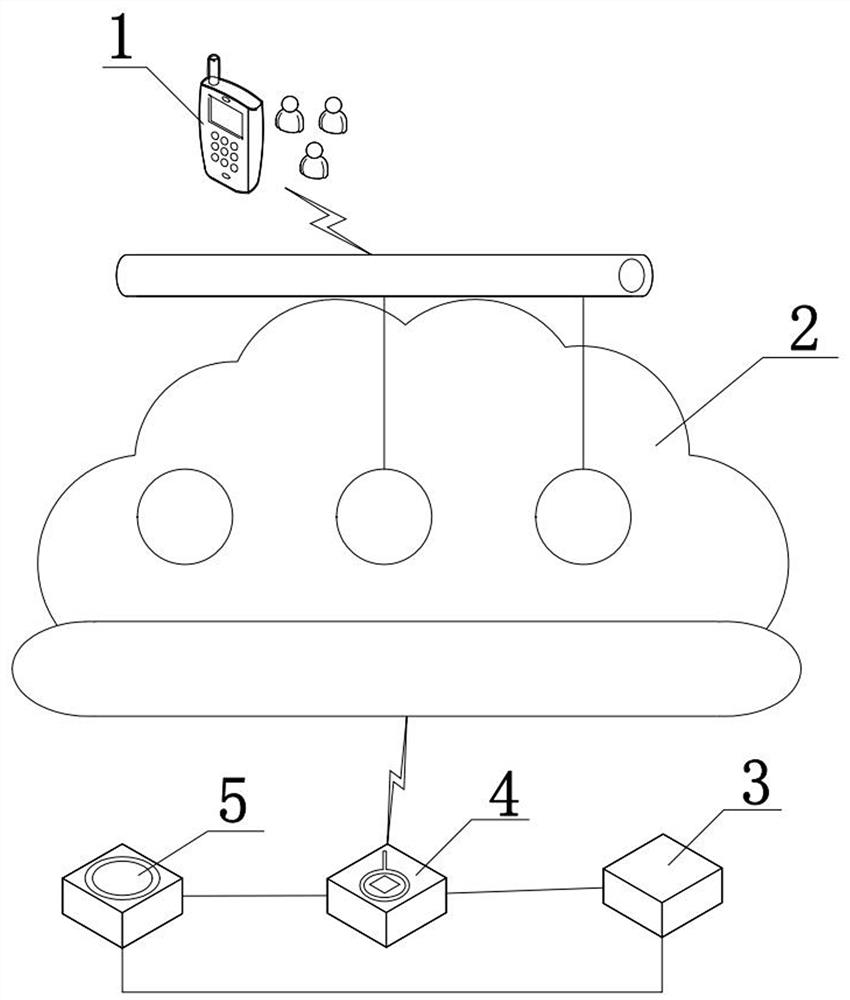

[0027]Such asfigure 2As shown, the battery thermal runaway monitoring system includes a detection controller 3, a data concentrator 5, a data remote transmission terminal 4, a big data platform 2 and a mobile phone APP1.

[0028]The detection controller 3 is arranged near or inside the battery compartment, the battery pack or the energy storage box. The detection controller 3 includes a CO sensor and an environmental monitoring sensor for monitoring the battery in the battery compartment, the battery pack or the energy storage box. Thermal runaway state. The CO sensor is a redundant design and includes a first CO sensor and a second CO sensor. When the detection controller 3 is in a normal working state, the first CO sensor works normally, and the second CO sensor is in a power-off mode. The second CO sensor serves as an online calibration reference sensor of the first CO

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap