Wiper Assembly

a wiper and assembly technology, applied in the direction of vehicle maintenance, vehicle cleaning, cleaning equipment, etc., can solve the problems of inconvenient installation, and achieve the effect of convenient installation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

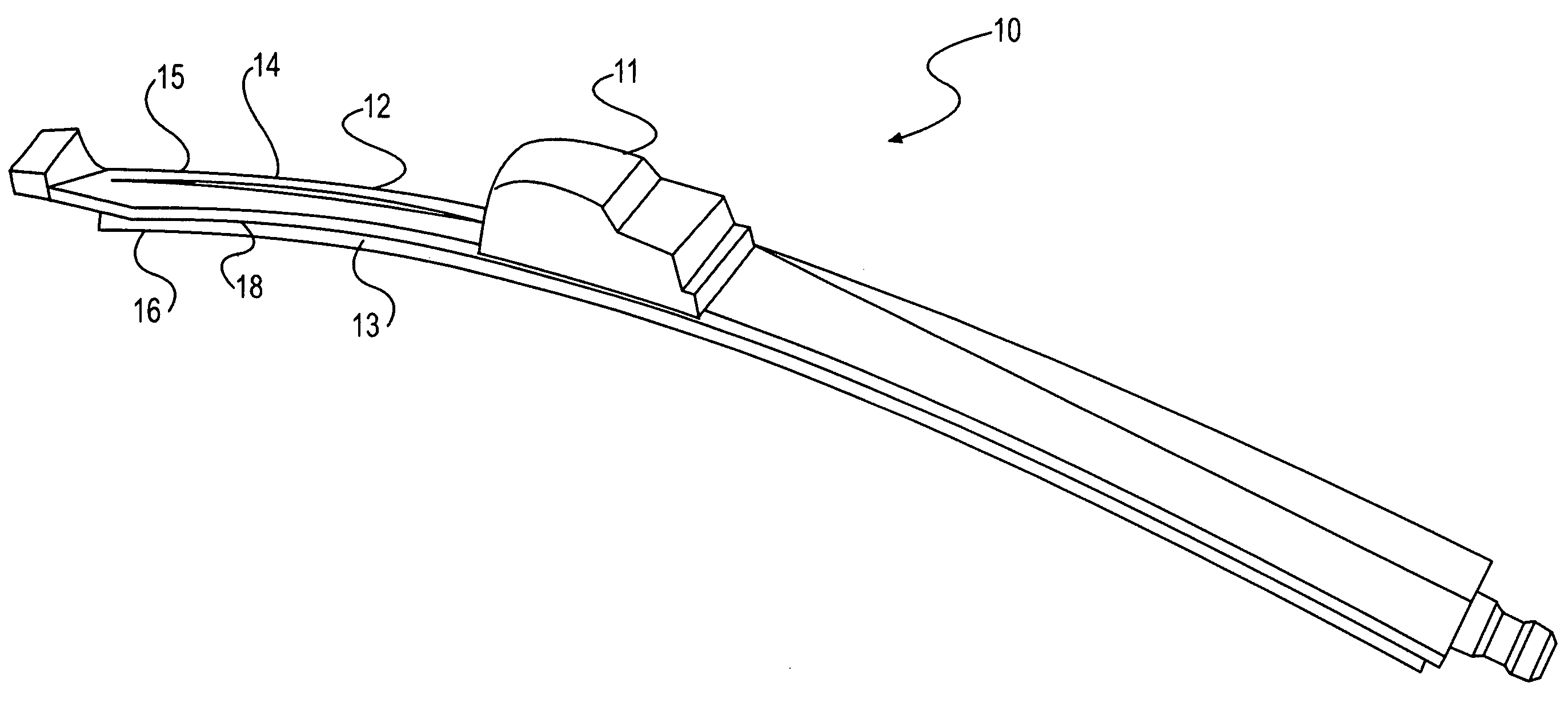

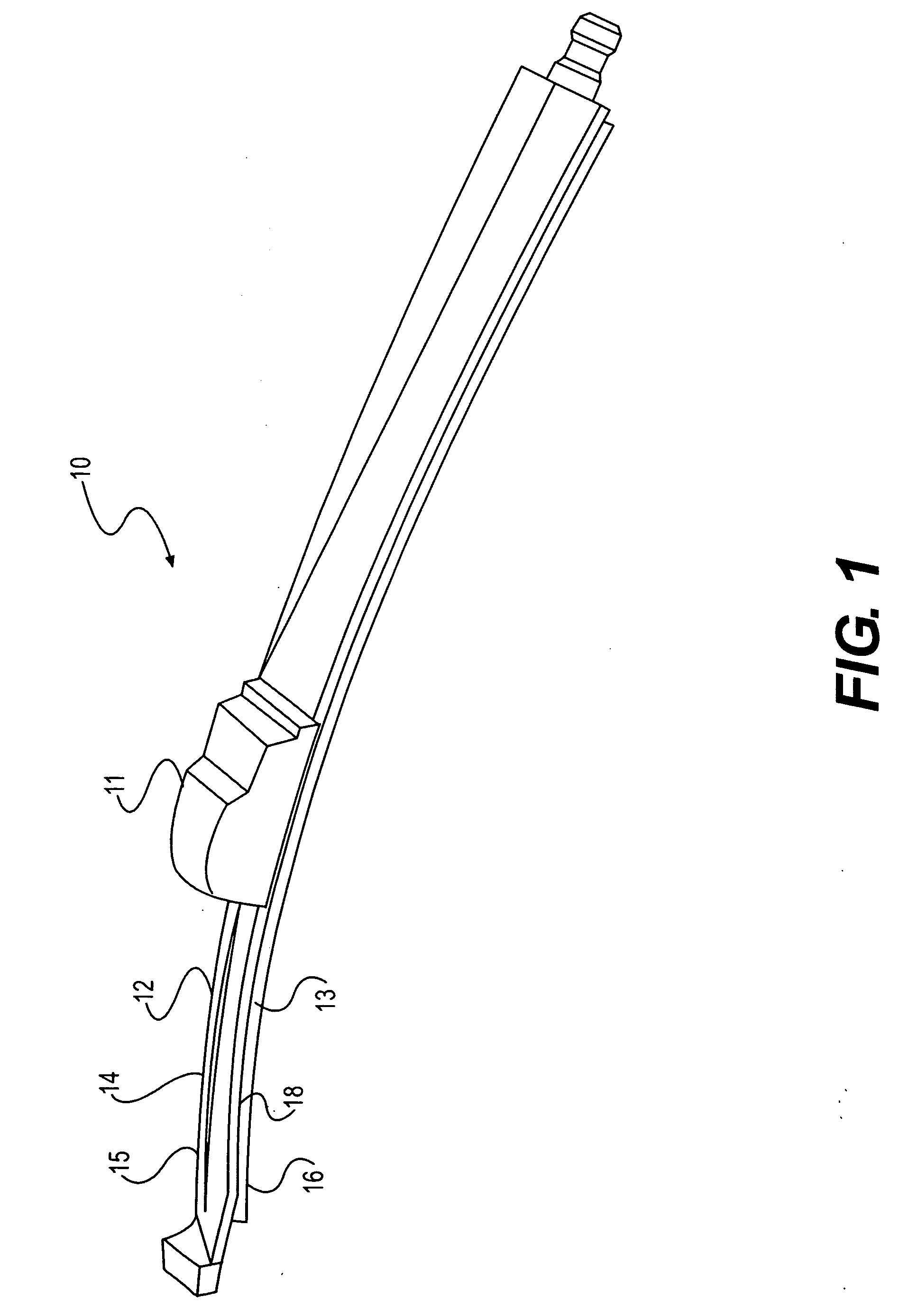

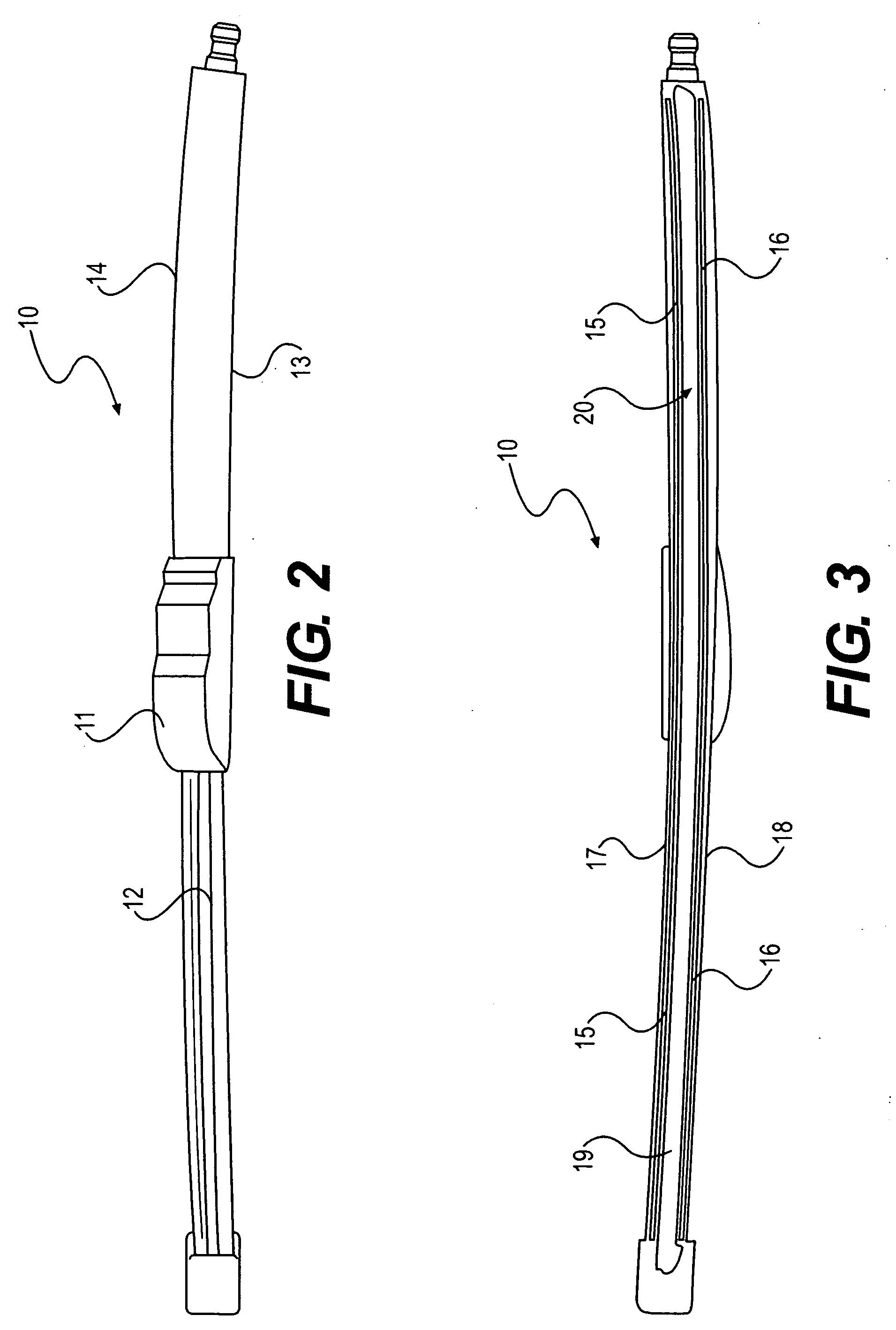

[0017]Referring to the drawings, a windshield wiper blade assembly is illustrated and designated generally as 10. The wiper blade assembly 10 may be installed and operated on an oscillating wiper arm said wiper blade assembly 10 being fixedly attached through attachment means 11 which is reciprocally adapted to connect with the wiper arm of a vehicle.

[0018]Specifically, the wiper blade assembly 10 is comprised of a frameless and flexible wiping blade elements carrying member 12 with centrally located attachment means 11 to connect said member 12 to the wiper arm of a vehicle. Front wall 13 and back wall 14 are respectively adapted to carry a pair of longitudinally extending spaced apart rubber-like wiping blade elements 15 and 16 terminating in wiping edges 17 and 18 being flexible yet resilient enough to perform wiping of the windshield.

[0019]A space 19 is thereby defined between the blade elements 15 and 16, the front wall 13 and the back wall 14 and finally the carrying member 12. A

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap