Load bearing stand

a technology for bearings and supports, applied in the direction of machine supports, domestic objects, applications, etc., can solve the problems of time-consuming and expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

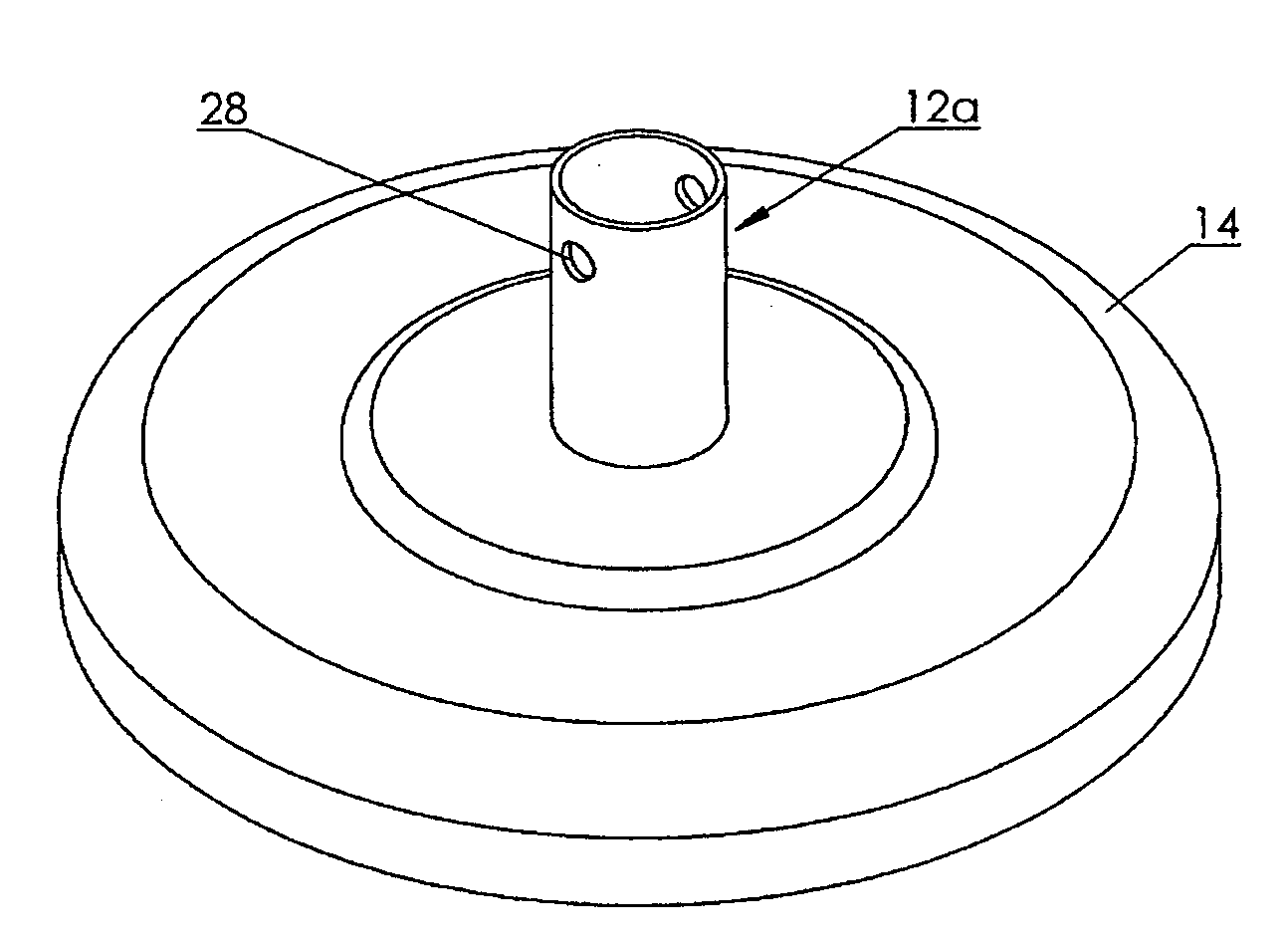

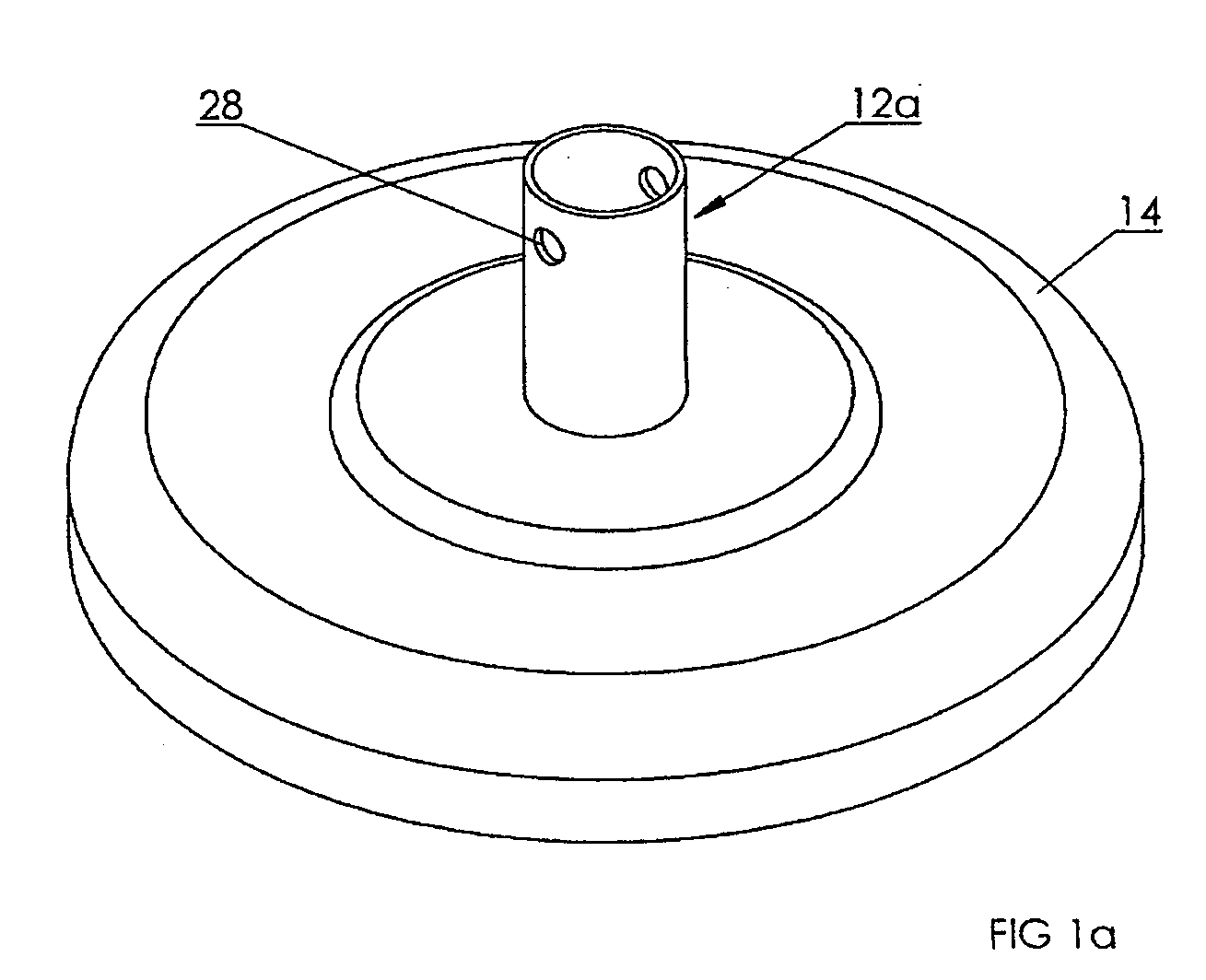

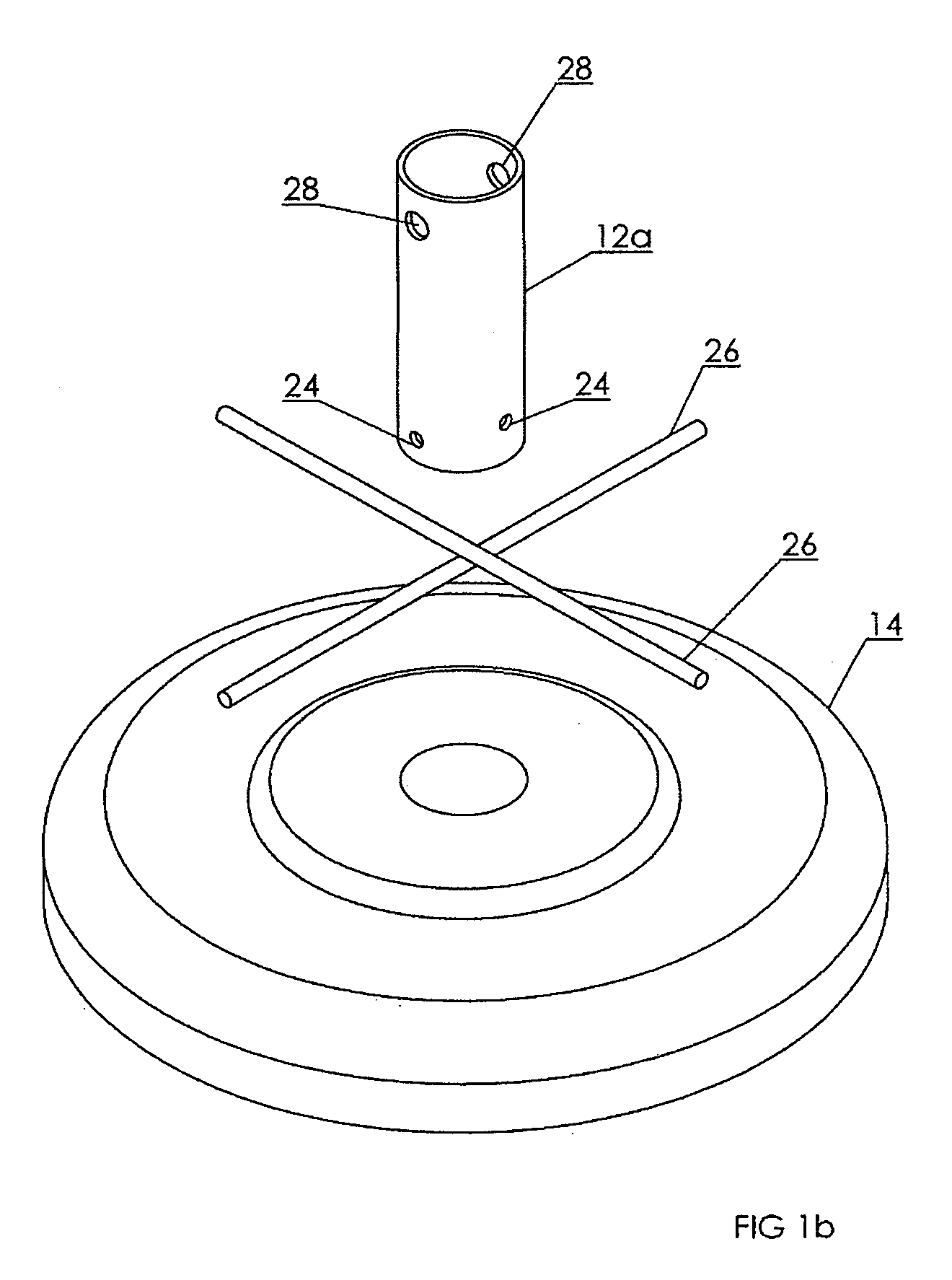

[0022]With reference to the drawings wherein similar characters of reference denote corresponding parts in each view, the load bearing stand 10 according to the present invention includes a rigid upright member 12 mounted in a wide stabilizing base 14. Upright 12 serves as a vertical extension of the base, onto the upper end of which may be mounted other supporting members depending on the load bearing application to which the stand is being put. For example, if a plurality of the load bearing stands are to support a pipe extending generally horizontally over the ground, and elevated above the ground, in one embodiment vertical extension members 16 are welded or otherwise rigidly affixed to the upright members 12 so as to elevate and support at upper ends of the vertical extension members 16 cross-members 18 onto which are mounted pipe 20. The combination of uprights 12, vertical extension members 16 and cross-members 18 may for example elevate pipe 20 up to approximately three (3) fee

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap