Toilet plunger cleaning receptacle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

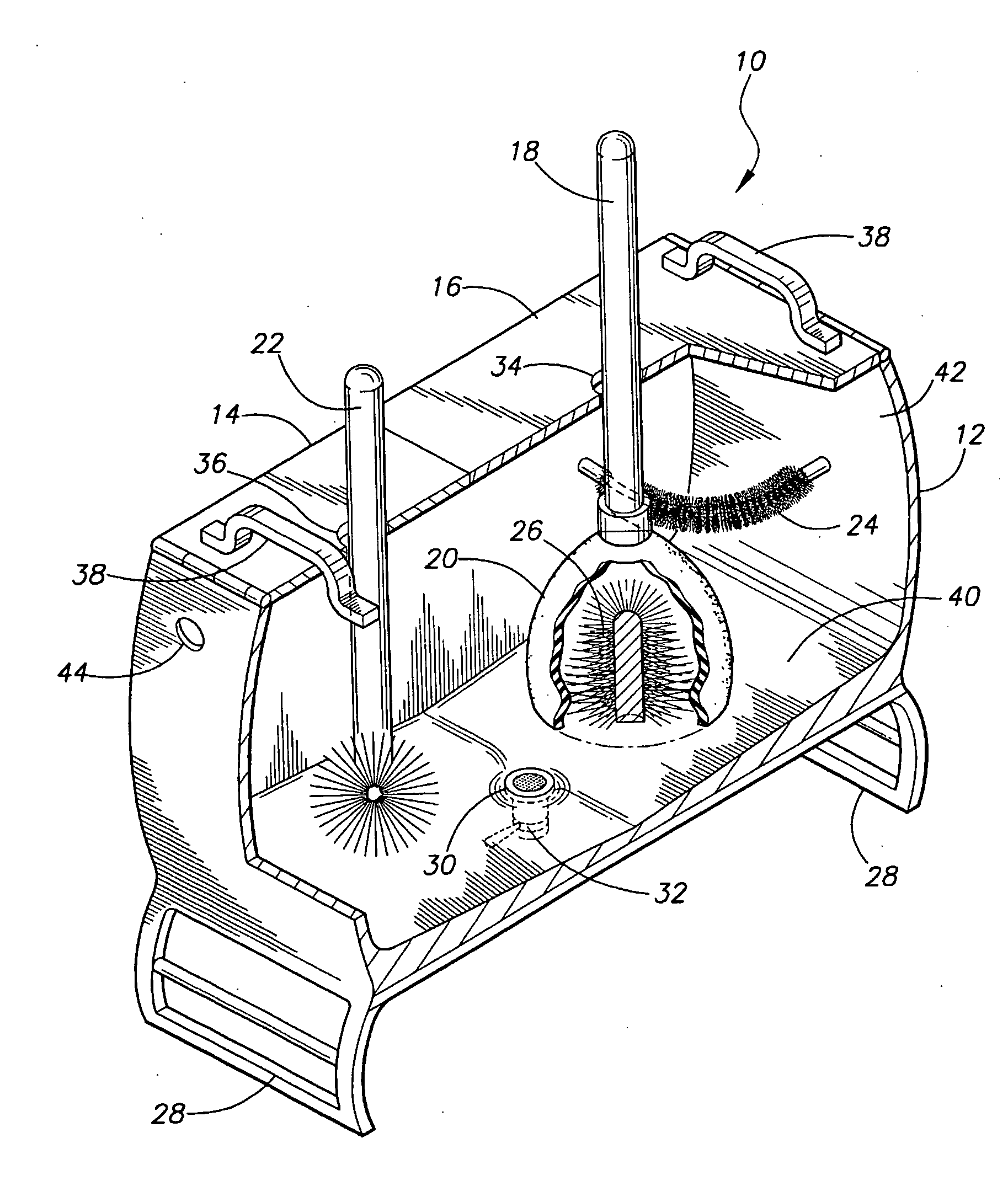

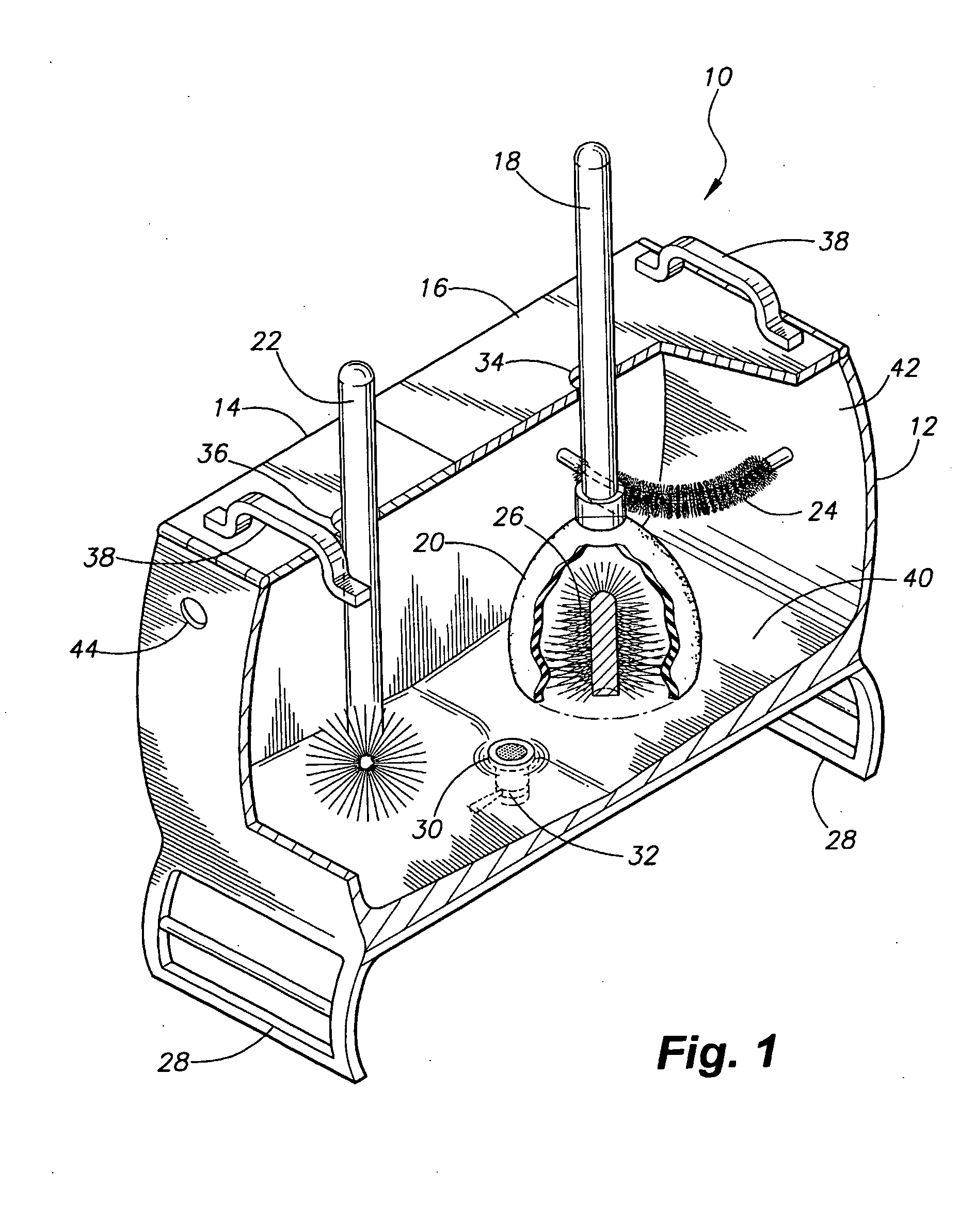

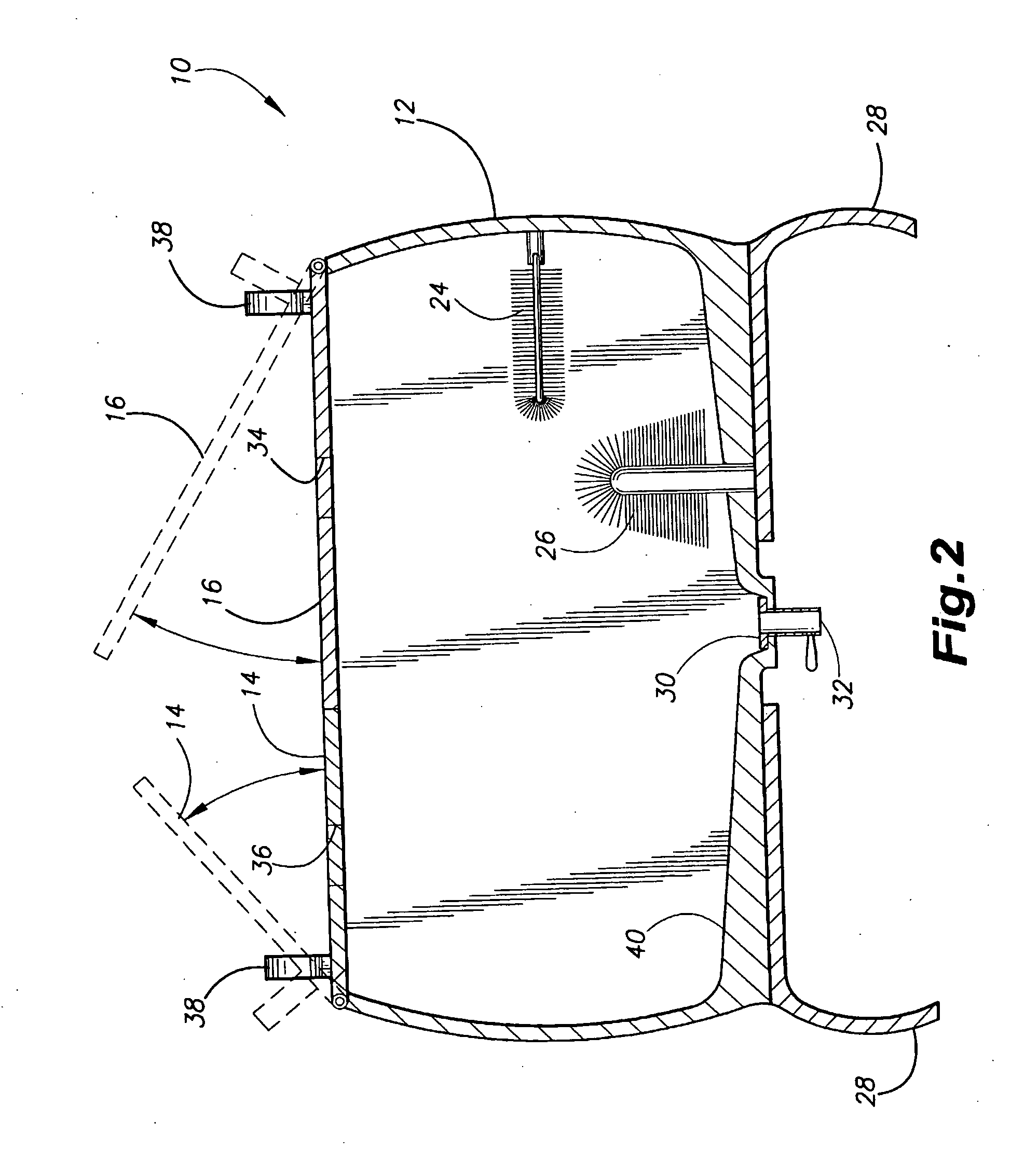

[0010]The present invention provides for a toilet plunger cleaning receptacle. The receptacle receives a sanitizing solution and includes a lower brush mounted to a lower interior surface of the receptacle, and an upper brush mounted to a sidewall of the receptacle, adjacent the lower brush. The receptacle receives a toilet plunger, and the bell of the plunger is positioned between the upper and lower brushes. Rotation of the plunger handle allows for the scrubbing of the plunger bell between the brushes. The receptacle is further designed to receive a separate toilet brush and also to hold a sanitizing solution. Both the plunger and toilet brush are immersed within the sanitizing solution to properly disinfect the toilet implements. The plunger cleaner is provided with a drain for drainage of the used sanitizing solution.

[0011]Referring now to FIGS. 1 and 2, there is shown a toilet plunger cleaning receptacle 10 of the present invention. Receptacle 10 includes a main tank 12 for recei

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap