Reducing Foulant Carry-Over or Build Up In A Paraffinic Froth Treatment Process

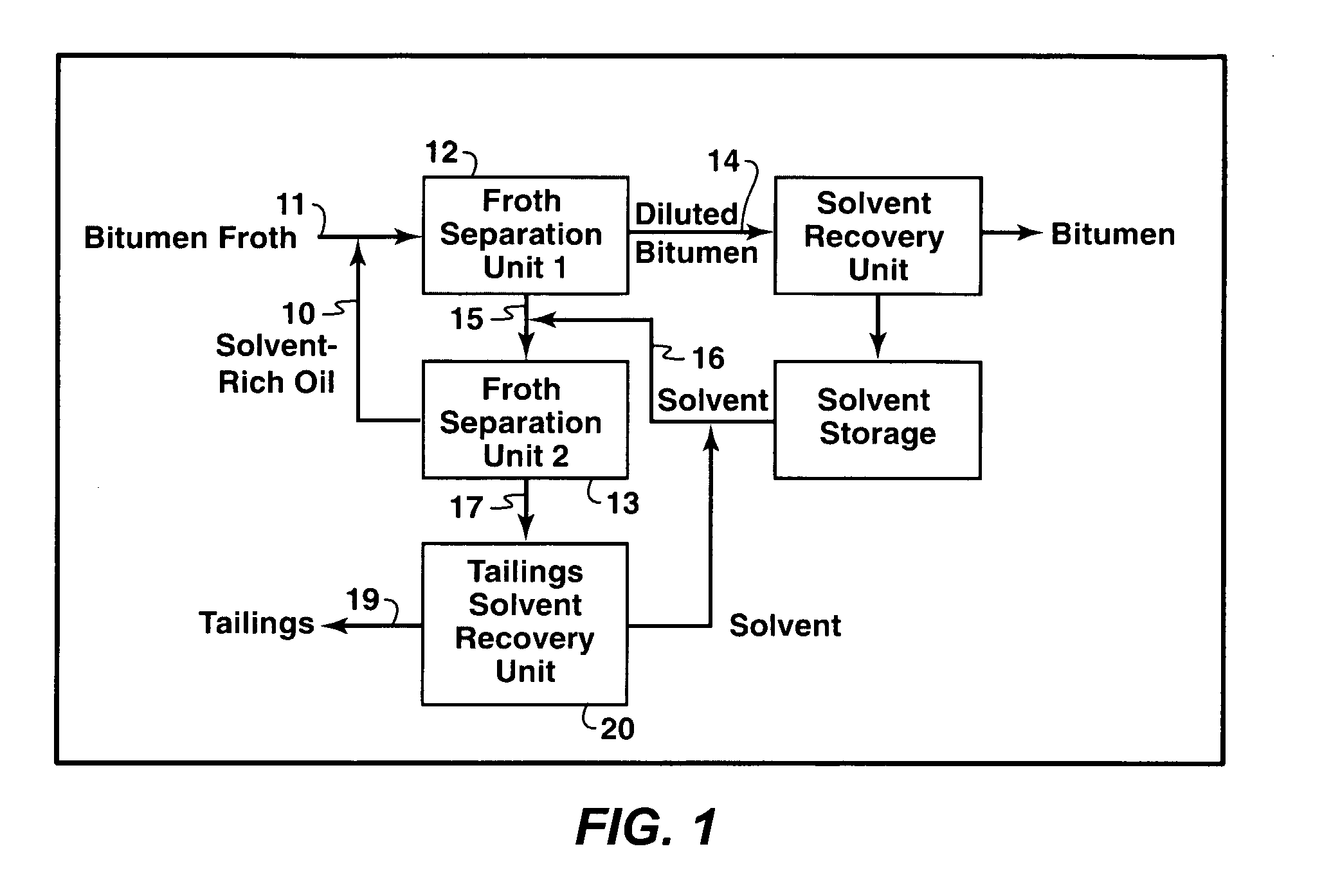

a paraffinic froth treatment and foulant technology, applied in the direction of hydrocarbon oil treatment, liquid hydrocarbon mixture production, corrosion/fouling inhibition of treatment apparatus, etc., can solve the problems of foulant build-up to a thickness, interfere with the normal operation of the process, etc., to reduce downstream foulant carry-over, reduce fouling, and reduce the effect of build-up in the vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Carbon Steel, Cement, and Ceramic Materials in FSU-1

[0079]Three materials: carbon steel, cement and a ceramic (Kalceram™, from Abresist Corporation, Urbana, Ind.) were evaluated as small coupons made from each material.

[0080]Each coupon was suspended by a steel wire from the top of the settler pipe section in FSU-1 (FIG. 4a). After being exposed continuously to the FSU-1 hydrocarbon over a period of 72 hours, all three coupons collected a significant amount of foulant.

[0081]This example shows that all three of these materials collected foulant that would otherwise be carried over downstream.

example 2

Carbon Steel, Cement and Ceramic Materials in FSU-2

[0082]Five materials: carbon steel, three ceramics (Abresist™, Alresist™ and Kalceram™, all from Abresist Corporation, Urbana, Ind.) and cement were evaluated in FSU-2. The coupons from these materials are shown in FIG. 5a before the run. After a 72-hour run, all the coupons collected a significant amount of foulant (FIG. 5b).

[0083]Each material was successful in collecting foulant material from the FSU-2 hydrocarbon stream, thereby demonstrating its effectiveness in reducing foulant build-up and carry-over to the equipment, conduits and vessels downstream of the FSU-2.

[0084]The higher amount of foulant build-up in all the FSU-2 coupons compared to FSU-1 coupons is evident when FIG. 5b in Example 2 is compared with FIG. 4b in Example 1. This is also evident when the carbon-steel coupon from FSU-2 (FIG. 6b) is compared with that from FSU-1 (FIG. 6a).

[0085]The friable nature of the foulant is also evident from FIGS. 6a and 6b, as some of

example 3

Repeat Evaluation of Materials of Example 1 and 2, in FSU-1 and FSU-2

[0088]This example shows the results from the repeat tests of those in Examples 1 and 2. The coupon materials and the exposure time of 72-hour in the repeat tests were the same as those in Examples 1 and 2. The weight gains by the coupons in the repeat tests are shown in FIG. 8.

[0089]The reproducibility in the weight gain by the coupons (by comparing FIG. 8 with FIG. 7) was reasonable in view of the fact that some foulant might have fallen off because of the friable nature of the foulant. As in Examples 1 and 2, all of the materials evaluated in the repeat tests collected foulant, with the Abresist™ showing the most collection, followed by carbon steel. The Alresist™ coupon in the repeat test showed weight gain which was in line with those by the other coupons, confirming the hypothesis that its relatively lower weight gain in Example 2 was due to some of the foulant falling off prior to weighing. Consistent with Exam

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap