Individual-grain seeding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

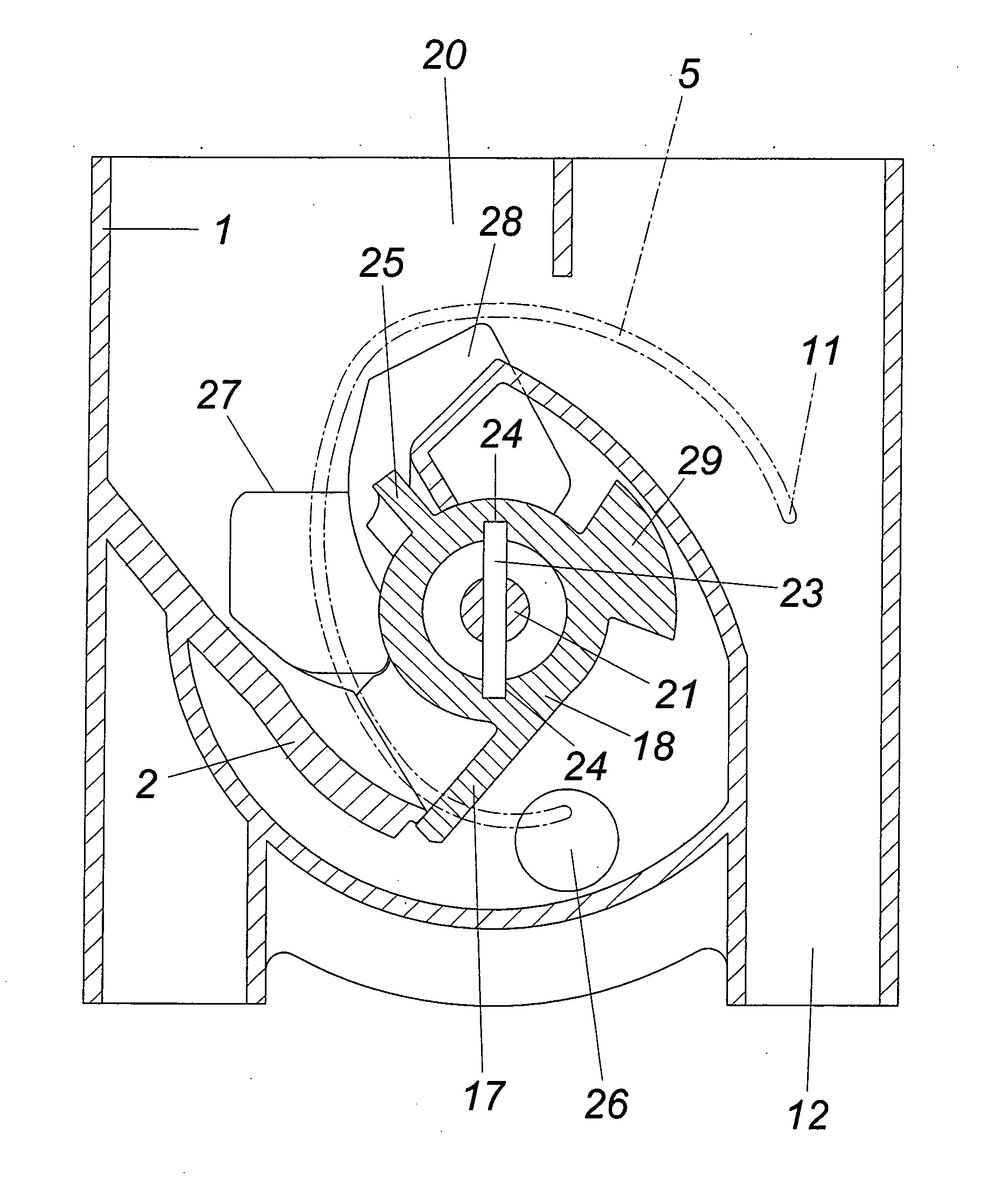

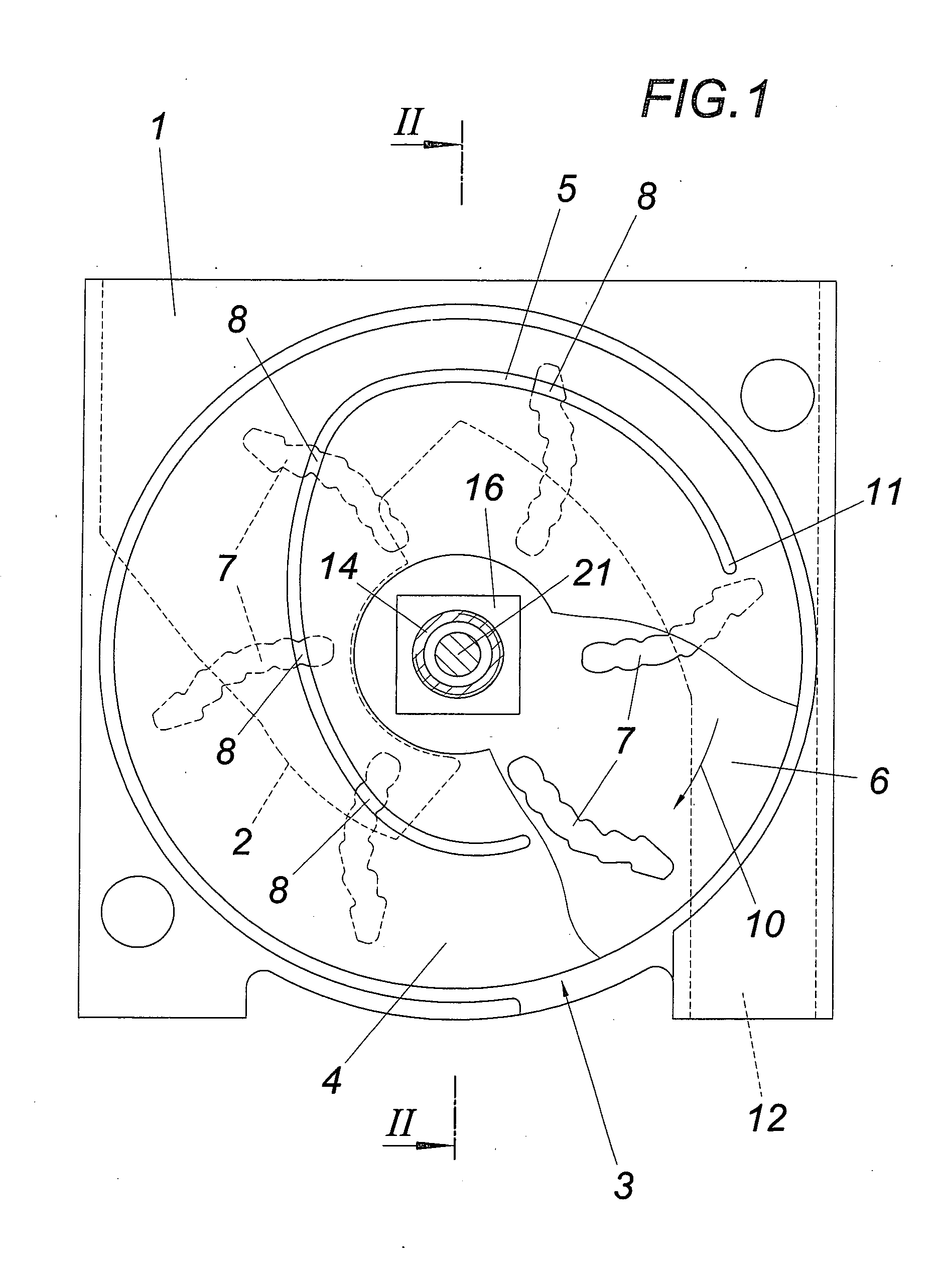

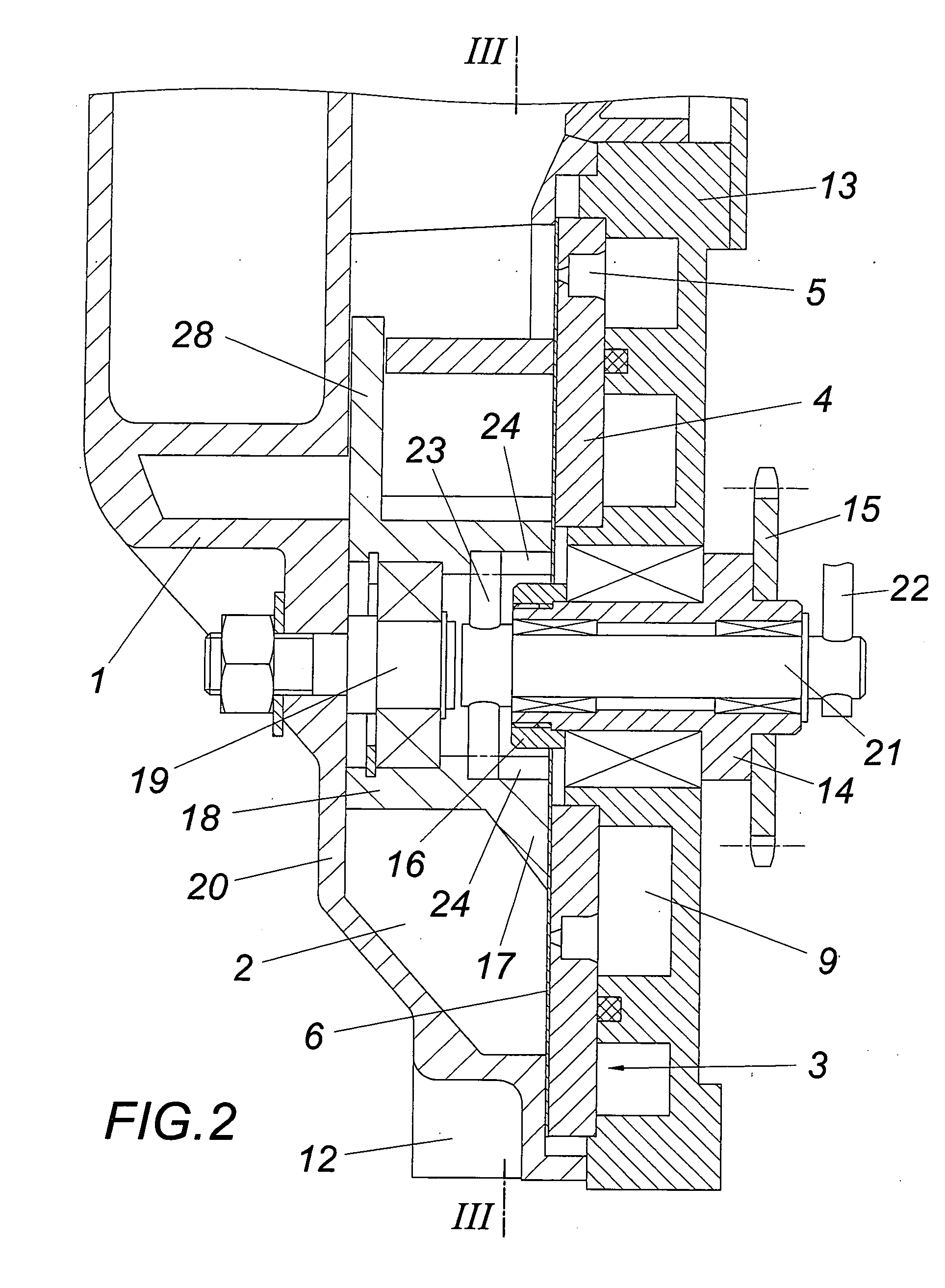

[0014]The illustrated single-grain sowing machine has a housing 1 in the sowing disc area, which forms a seed hopper 2, and is covered frontally by a sowing disc 3. This sowing disc 3 is composed of a housing-fixed disc body 4 having a guide slot 5 and a conveyor disc 6, which is provided with driver slots 7, which extend over the radial extension area of the guide slot 5 and run essentially radially. Intake openings 8 for seed grains poured into the seed hopper 2 thus result in the overlap area between the guide slot 5 and the driver slots 7. To suction the seed grains at the intake openings 8, a partial vacuum chamber 9 is provided on the side of the sowing disc 3 facing away from the seed hopper 2, as can be inferred from FIG. 2. The seed grains are suctioned on the intake openings 8 in the floor area of the seed hopper 2 while isolating the seed grains when the driver slots 7 reach the area of the seed hopper 2 during the rotation of the conveyor disc 6 in the conveyor direction 10

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap