Device for Producing Dry Aerosol (Varians)

a technology of aerosol and production equipment, which is applied in the field of medical equipment, can solve the problems of inability to ensure the desired concentration of aerosol in the treatment room, and achieve the effects of high operational reliability, high quality of generated aerosol, and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

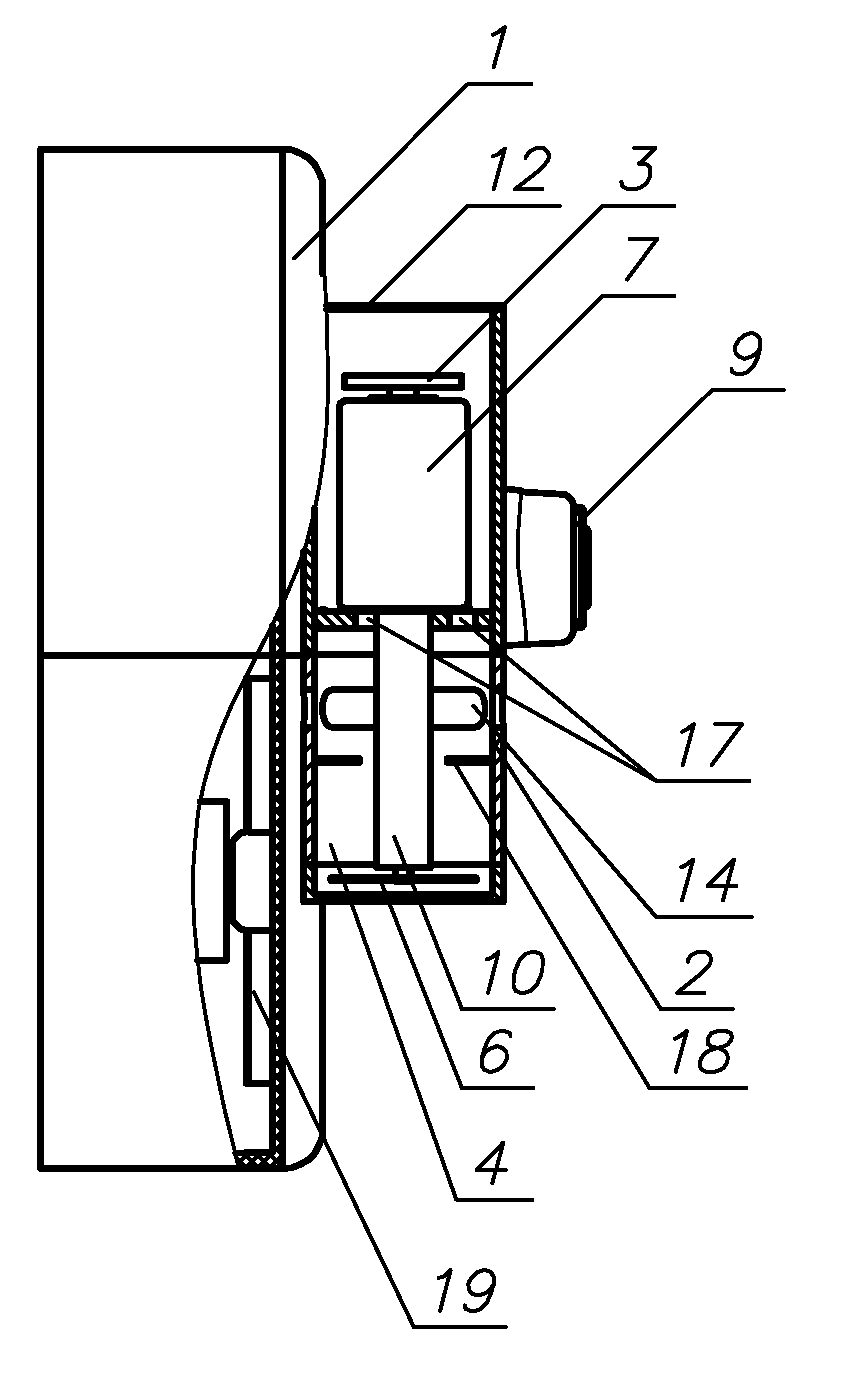

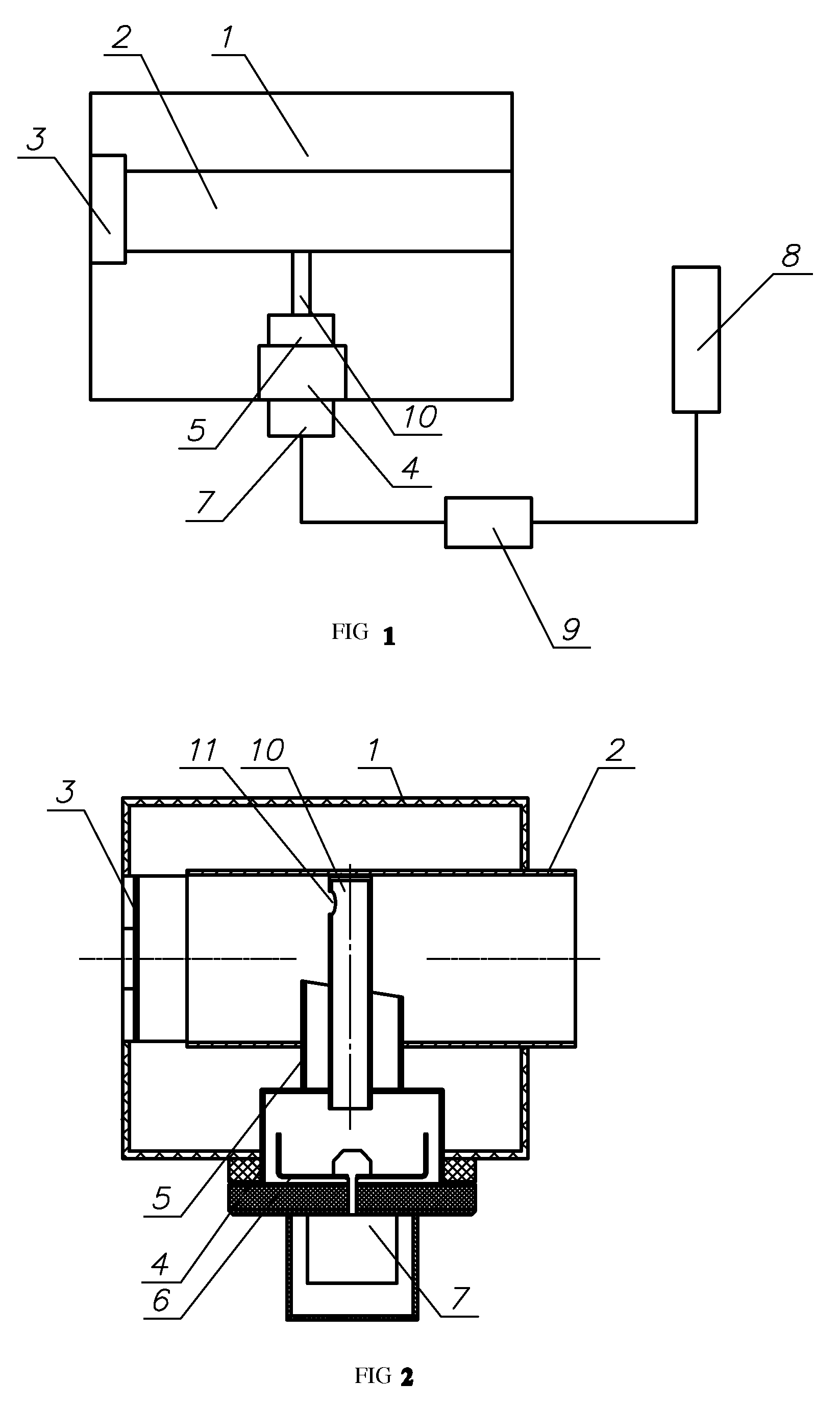

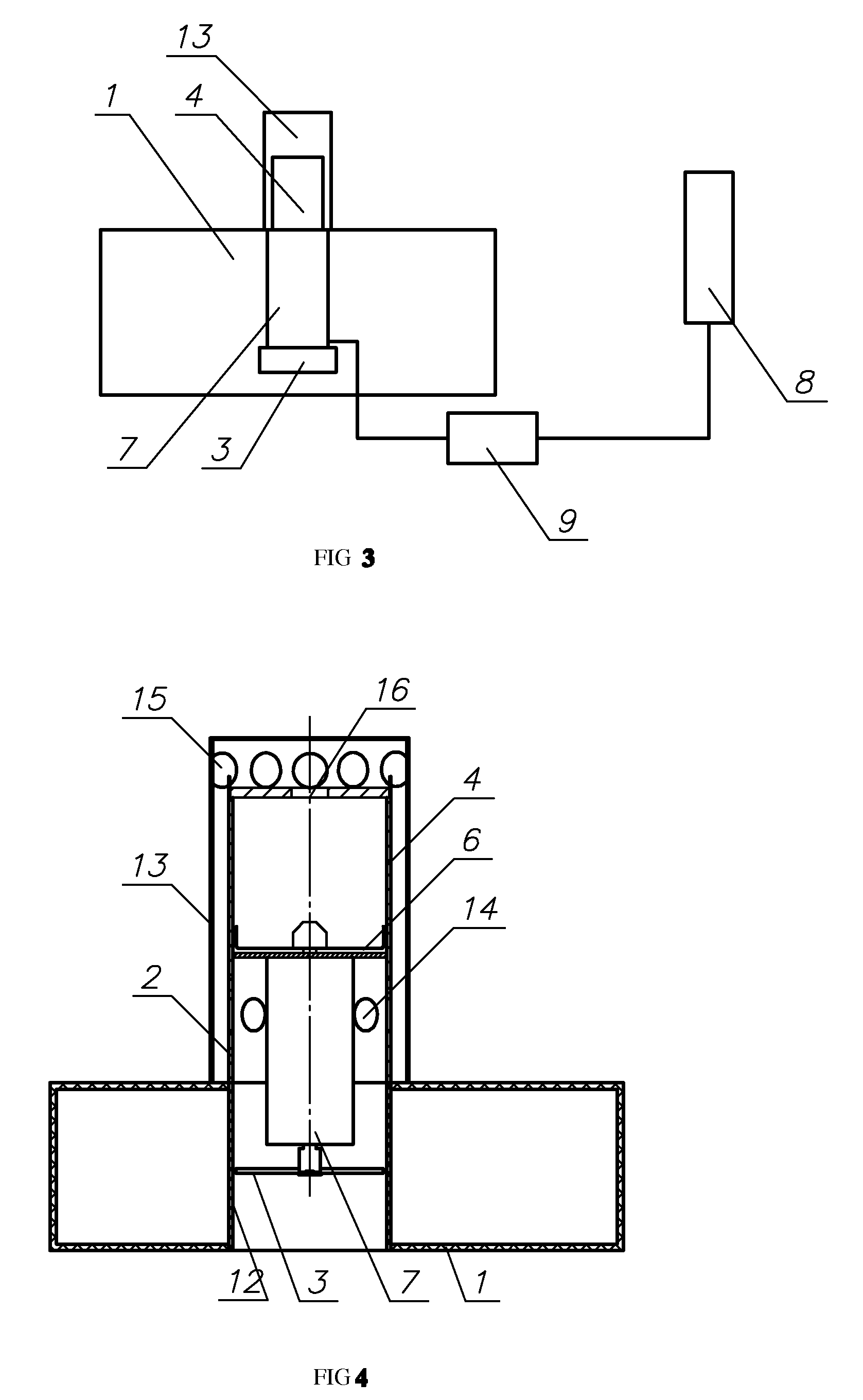

[0041]The first variant of a device for producing dry aerosol comprises a casing 1, an airway 2 with a supply air booster 3, placed in a chamber 4, joined through an outlet 5 with an airway 2, a salt mill as a grinding body 6 with a rotary drive 7, aerosol concentration detector 8, connected to a control unit 9 connected to a switch of mill drive 7, an air tube 10 is fixed in an outbound channel 5 of a chamber 4, its lower part is located atop a grinding body 6 and its upper part—in an airway 2, in the upper side of an air tube 10 there is a hole 11 directed toward an air flow in an airway 2, and a gap between the side wall of a chamber 4 and a grinding body 6 is 3-10 mm and a gap between the underside of a chamber 4 and a grinding body 6 is 1-5 mm.

[0042]In the first variant of a device for producing dry aerosol the following is preferable:

[0043]an outbound channel 5 in a chamber 4 is perpendicular to a longitudinal axis of an airway 2;

[0044]an upper part of an outbound channel 5 in a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap