Flowpack Tray

a technology of flowpack and tray, which is applied in the direction of liquid handling, closure using stoppers, caps, etc., can solve the problems of limiting the performance of the tray, the complexity and cost of depositing such layers on three-dimensional structures, and the inability to thermoform without losing the barrier properties, etc. problem, to achieve the effect of limiting the use of such layers to very specific applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

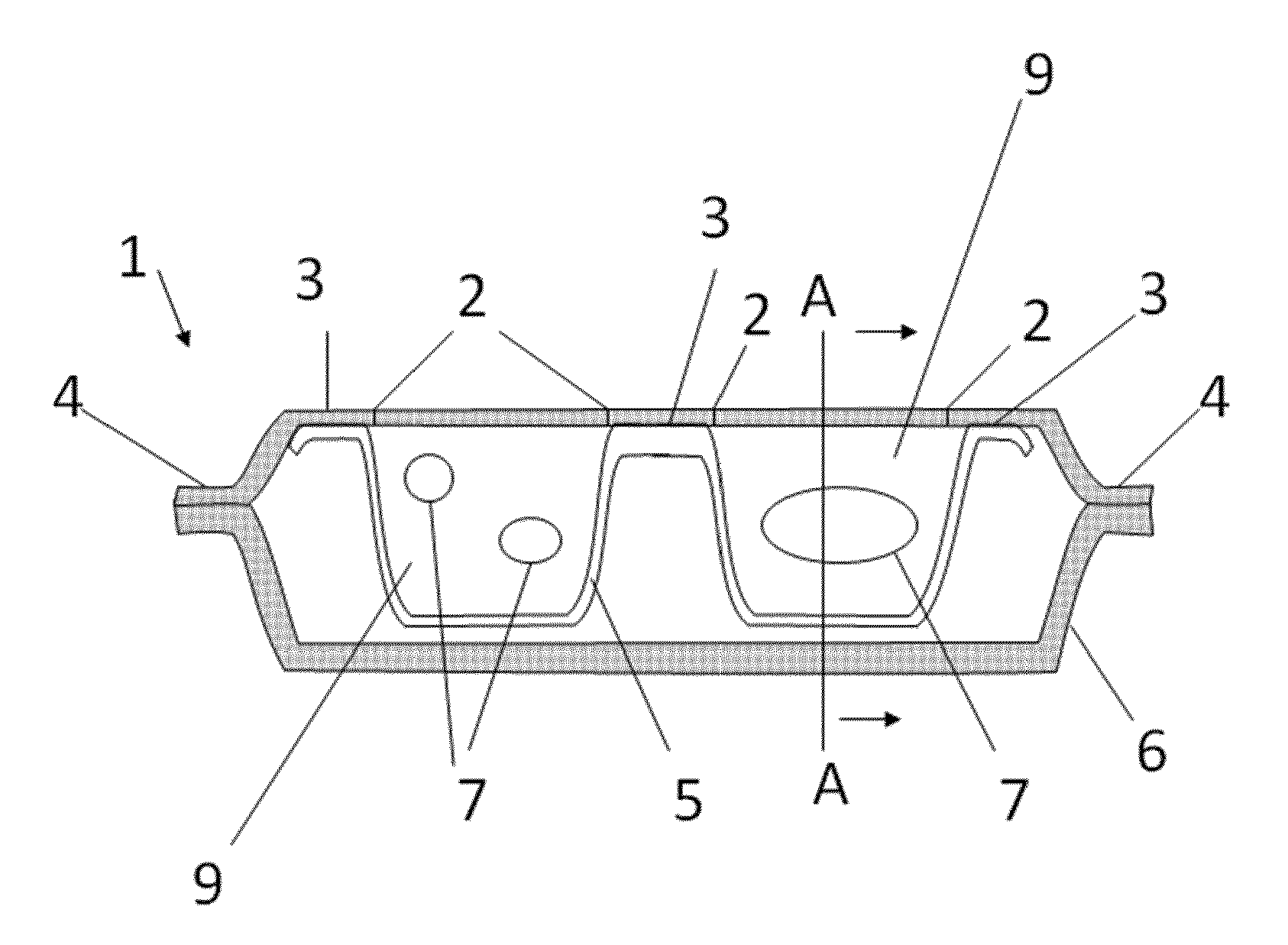

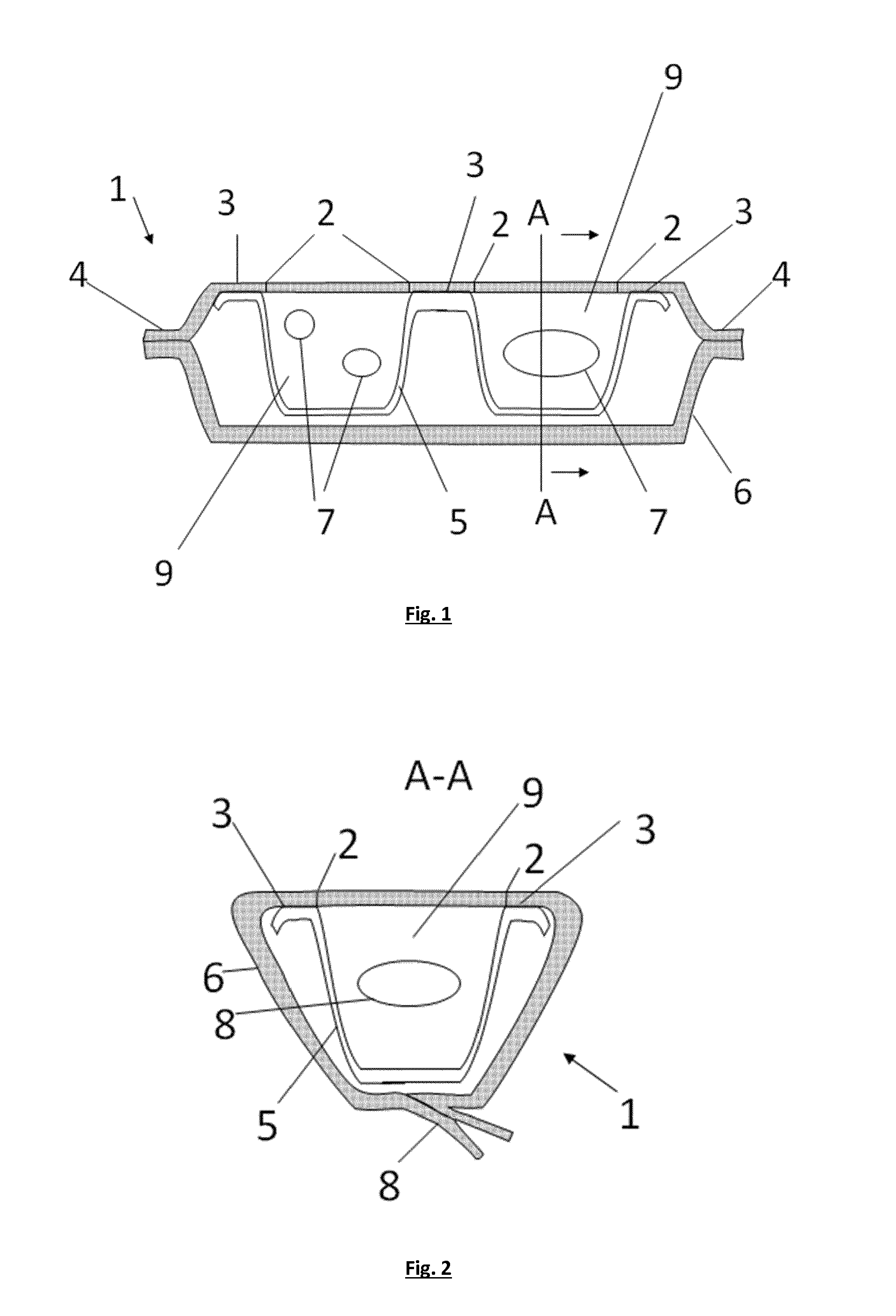

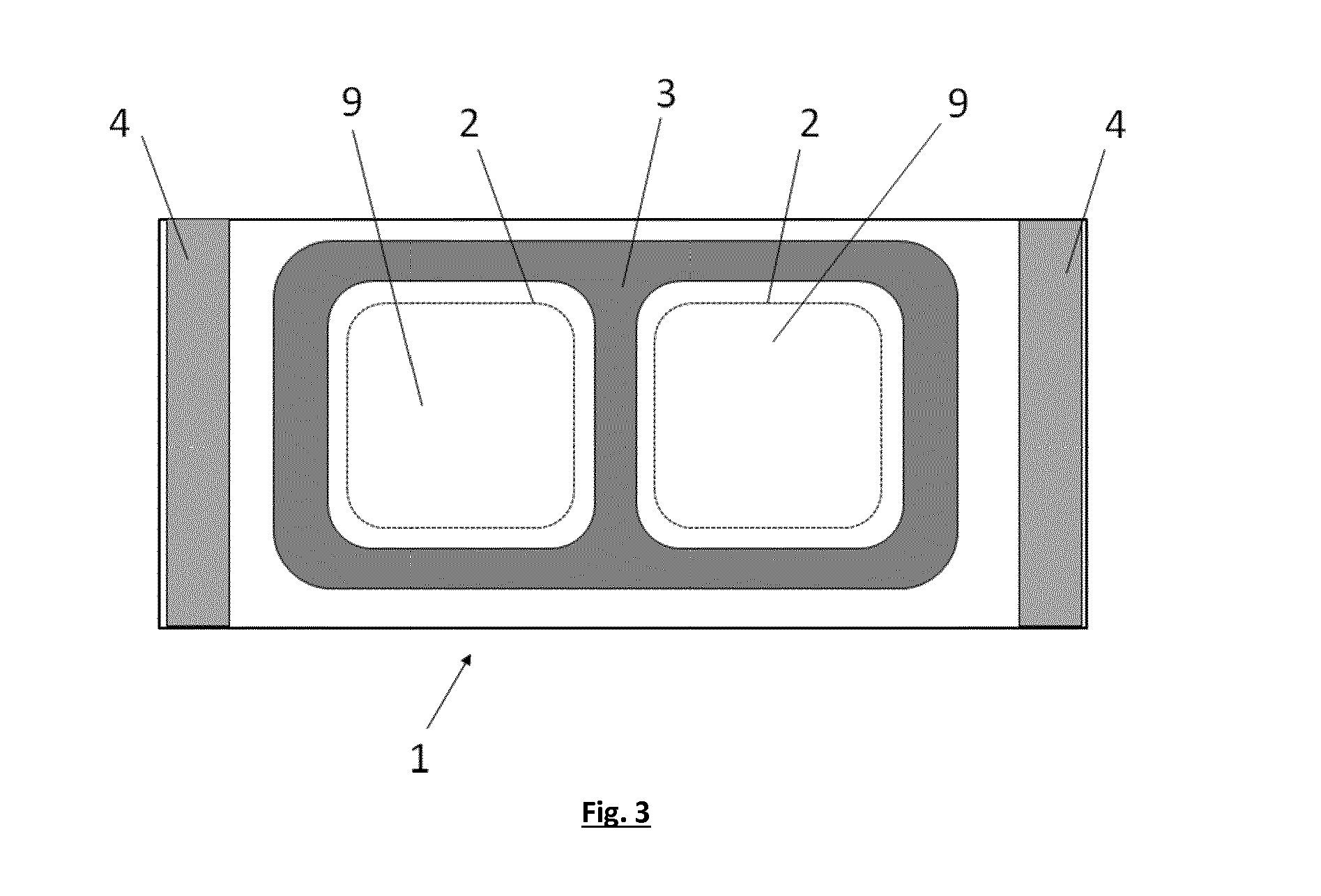

[0043]The present invention is related to a flowpack 1 enclosing a tray 5 comprising one or more cavity(ies), the film 6 forming said flowpack 1 being sealed against said tray 5 and forming a lid closing the individual cavity(ies) 9, said lid being part of the initial film of the flowpack.

[0044]Such flowpack 1 presents several advantages in comparison with prior-art tray packaging. As a first advantage, there is no need for a secondary packaging, as the flowrap film 6 completely encloses the tray 5.

[0045]As a further advantage, the flowpack 1 of the invention can be easily produced on modified horizontal form fill and seal machines or thermoform fill seal machines.

[0046]For example, filled trays can be fed to an horizontal form fill seal machine, wherein the flowpack 1 is formed and sealed around the filled tray, the inner surface of the flowpack 1 being sealed in a subsequent step on the top surface of the tray, thereby closing the individual cavities.

[0047]Alternatively, it is also p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap