Liquid crystal display apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

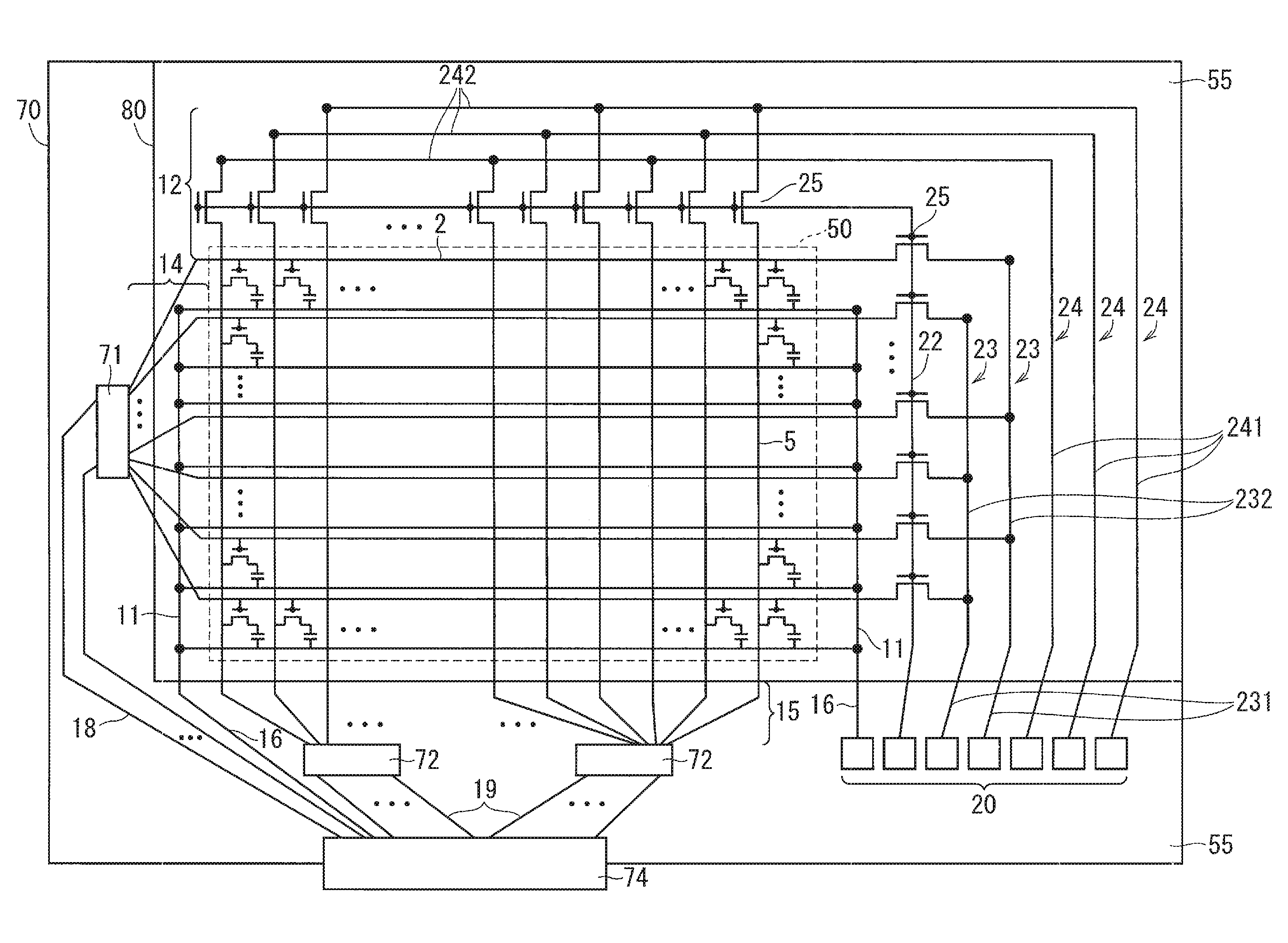

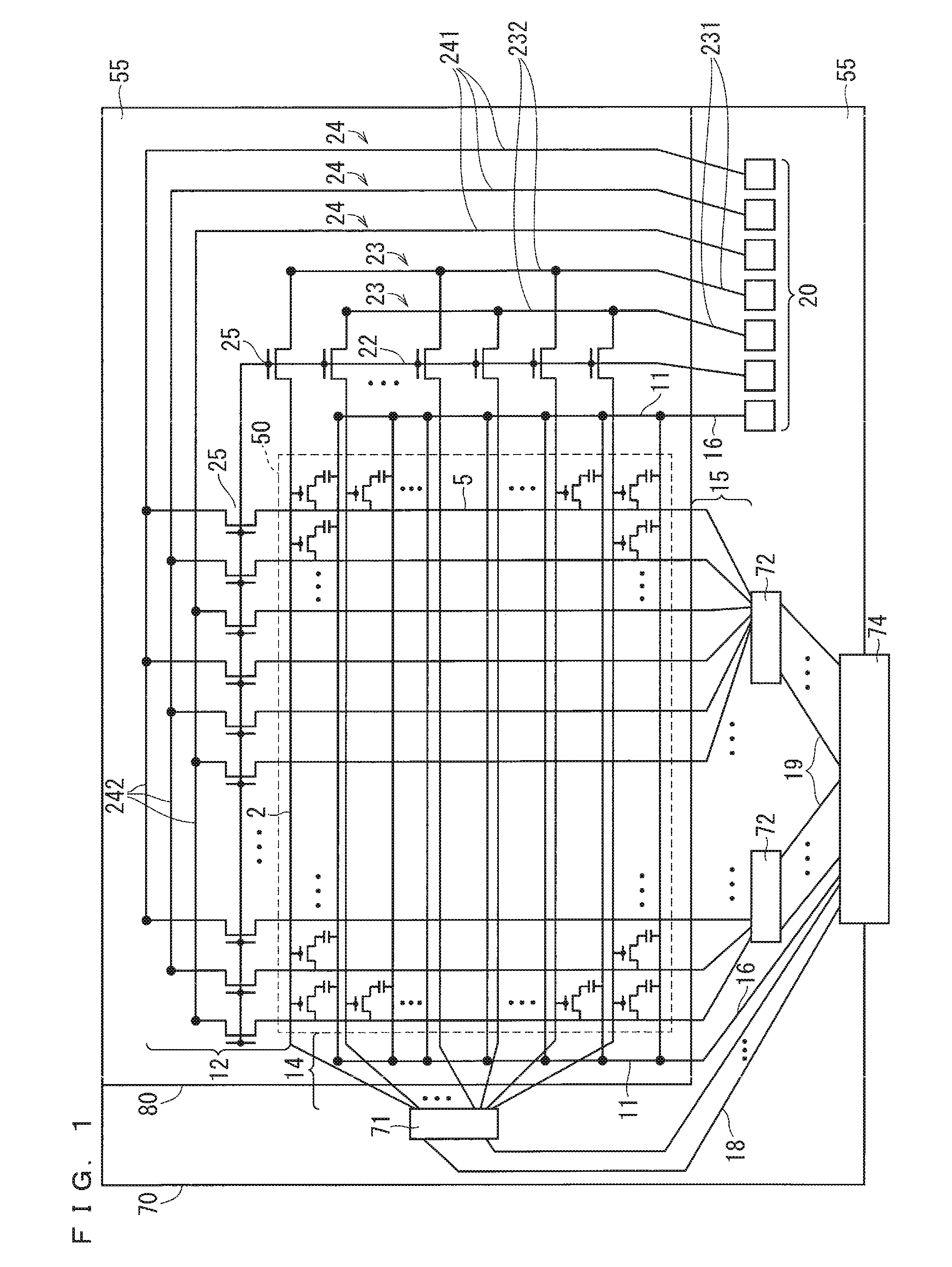

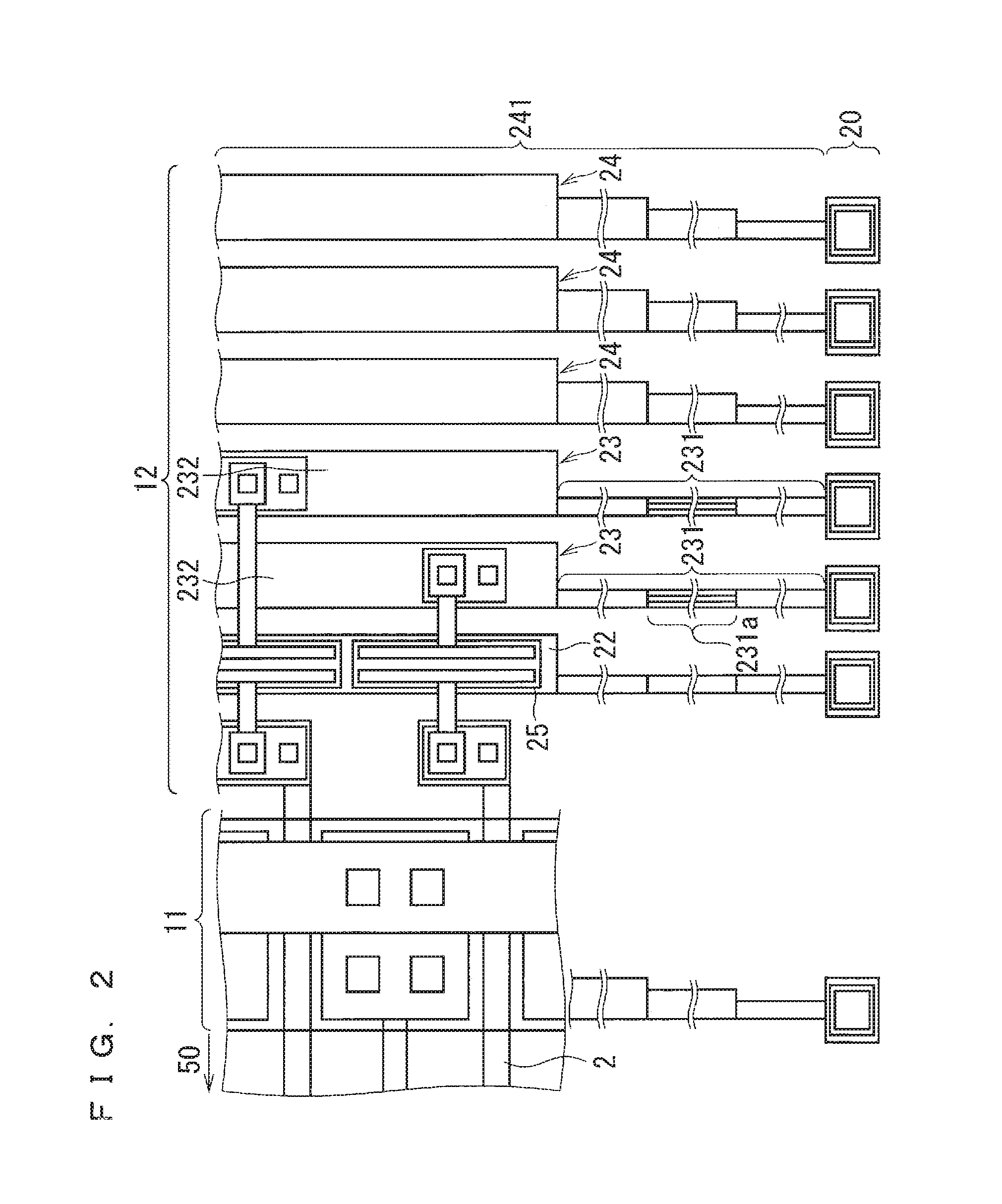

[0020]FIG. 1 is a plan view showing a configuration of a liquid crystal display apparatus according to a first preferred embodiment. FIG. 2 is a partially enlarged view of a collective drive lighting inspection circuit 12 of the liquid crystal display apparatus according to the first preferred embodiment. The same or similar components of display devices according to other preferred embodiments are denoted by the same references of the components of the liquid crystal display apparatus according to the first preferred embodiment shown in FIG. 1.

[0021]As shown in FIG. 1, a plurality of pixels being display units of an image are provided in a display region 50 indicated by dotted lines. A thin film transistor (TFT) being a switching element that supplies display voltage to a pixel electrode is disposed in each of the pixels. A member formed of a substrate on which the TFTs are mounted is referred to as a TFT array substrate 70. The TFT array substrate 70 includes the TFTs in each of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap