Piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

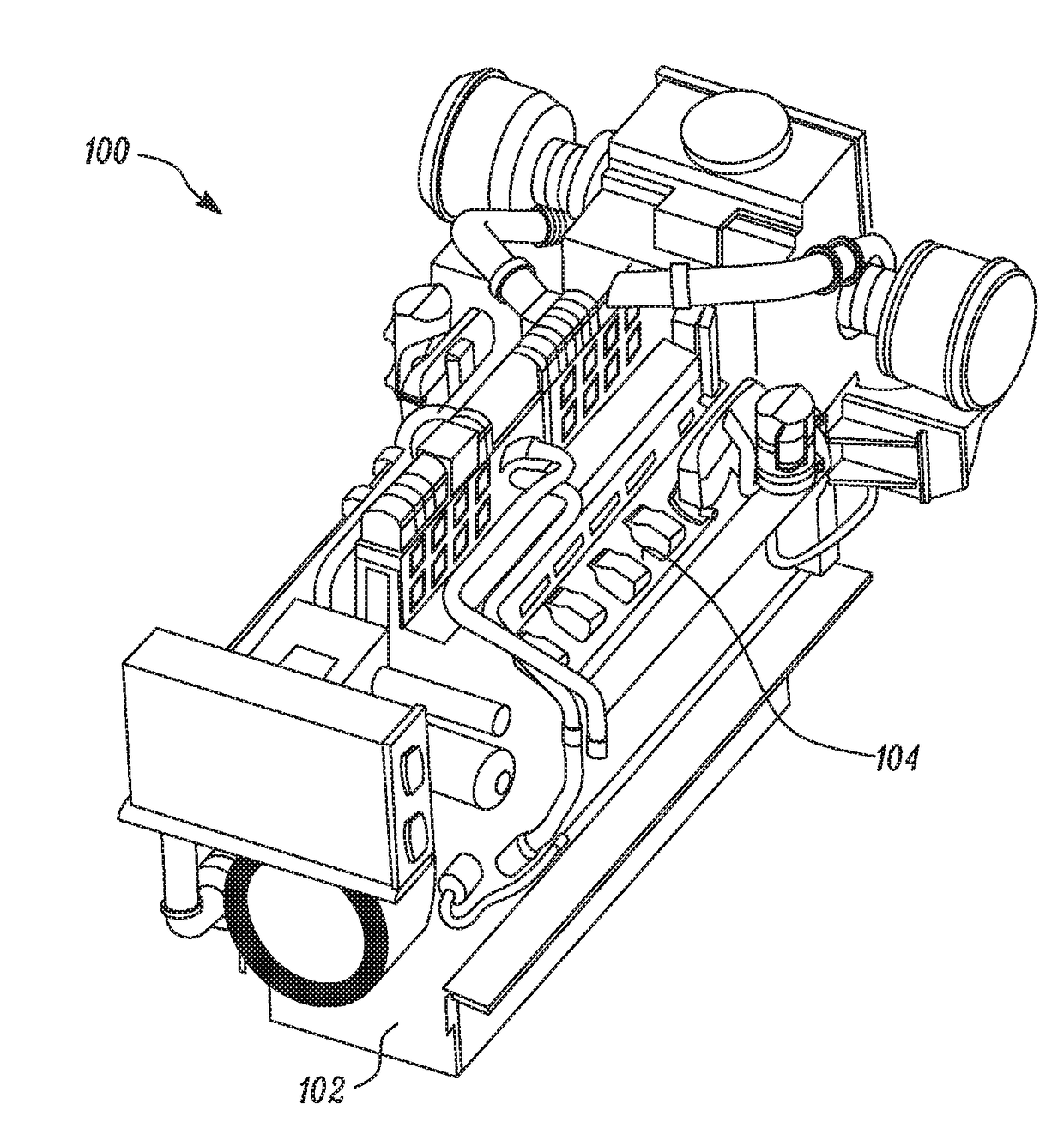

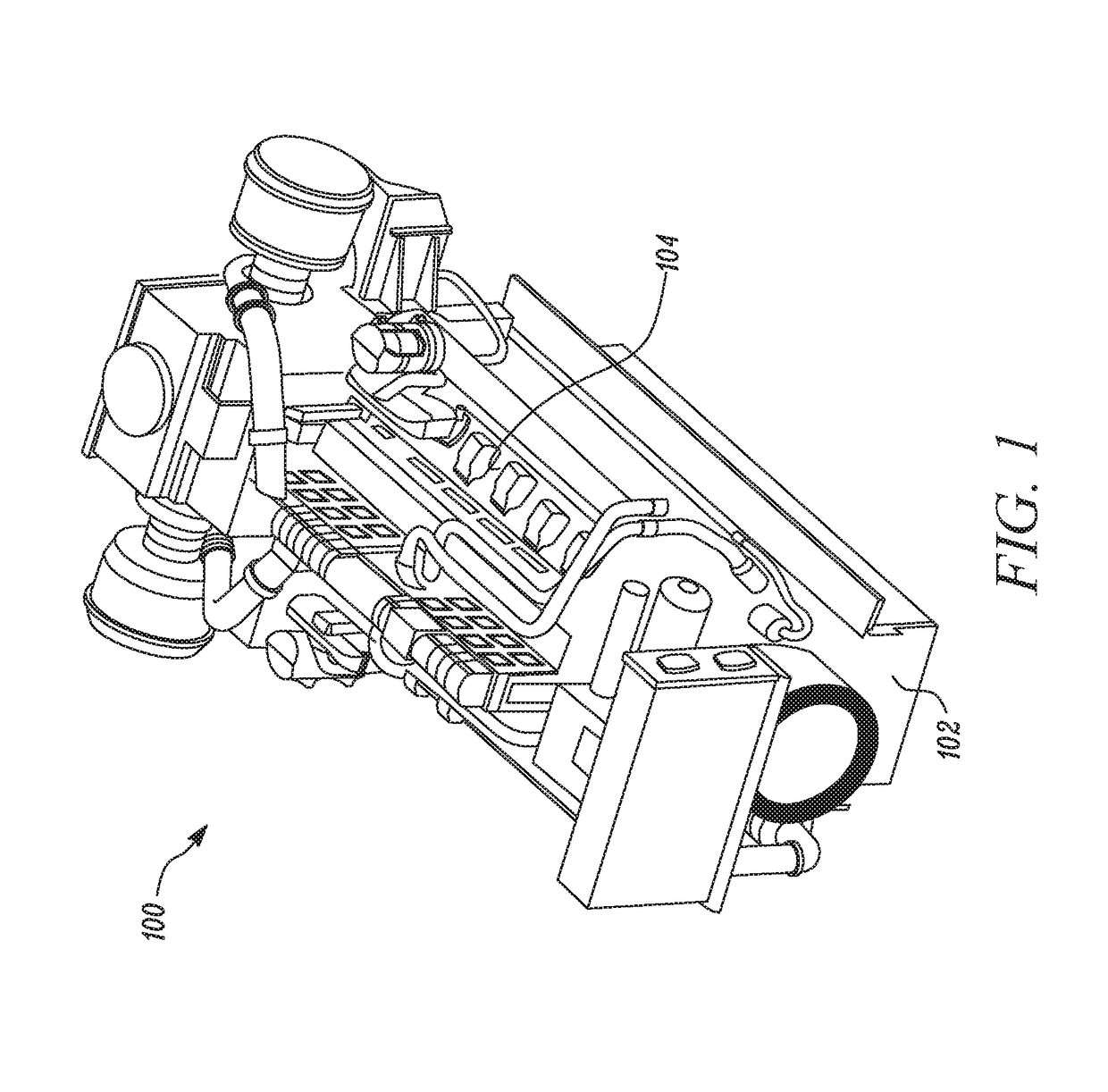

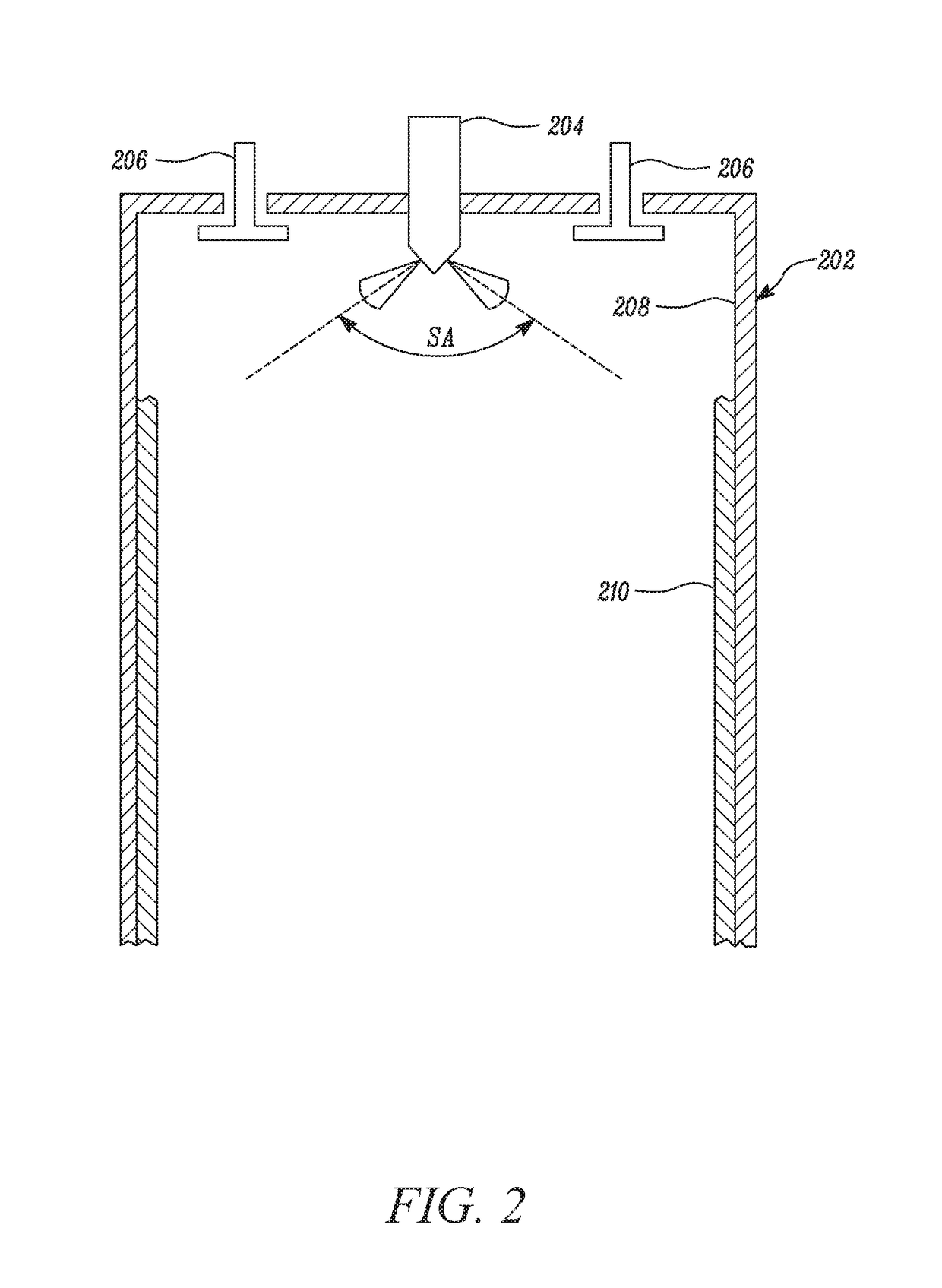

[0012]Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or the like parts. Referring to FIG. 1, an exemplary engine 100 is illustrated. The engine 100 is an internal combustion engine powered by any fuel known in the art, such as natural gas, diesel, or a combination thereof. More specifically, in the illustrated embodiment, the engine 100 is a Direct Injected Gas (DIG) engine. As such, the engine 100 employs two fuels for combustion, viz., a combination of natural gas and diesel. The natural gas and diesel may be simultaneously or sequentially injected into a cylinder 202 (shown in FIG. 2) of the engine 100, based on application requirements, in a ratio of up to 99:1 and may vary based on application requirements. The two fuels may be directly injected into the cylinder 202, simultaneously or sequentially, by a fuel injector 204 (shown in FIG. 2) known in the art adapted for dual fuel injection.

[0013]In other embodiments, the engin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap