Hooded Muzzle Brake Flash Suppressor

a technology of muzzle brake and flash suppressor, which is applied in the direction of muzzle attachment, etc., can solve the problems of increasing the level of firearm report exceeding the decibels, affecting the hearing of the shooter and all nearby observers, and reducing the recoil effect of the muzzle brake, limiting noise, and reducing noise perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]While the invention is susceptible of various modifications and alternative constructions, different construction materials other than listed herein, certain illustrated embodiments thereof have been shown in the drawings and will be described below in detail. It should be understood, however, that there is no intention to limit the invention to the specific form disclosed, but, on the contrary, the invention is to cover all modifications, alternative constructions, and equivalents falling within the spirit and scope of the invention as defined in the claims.

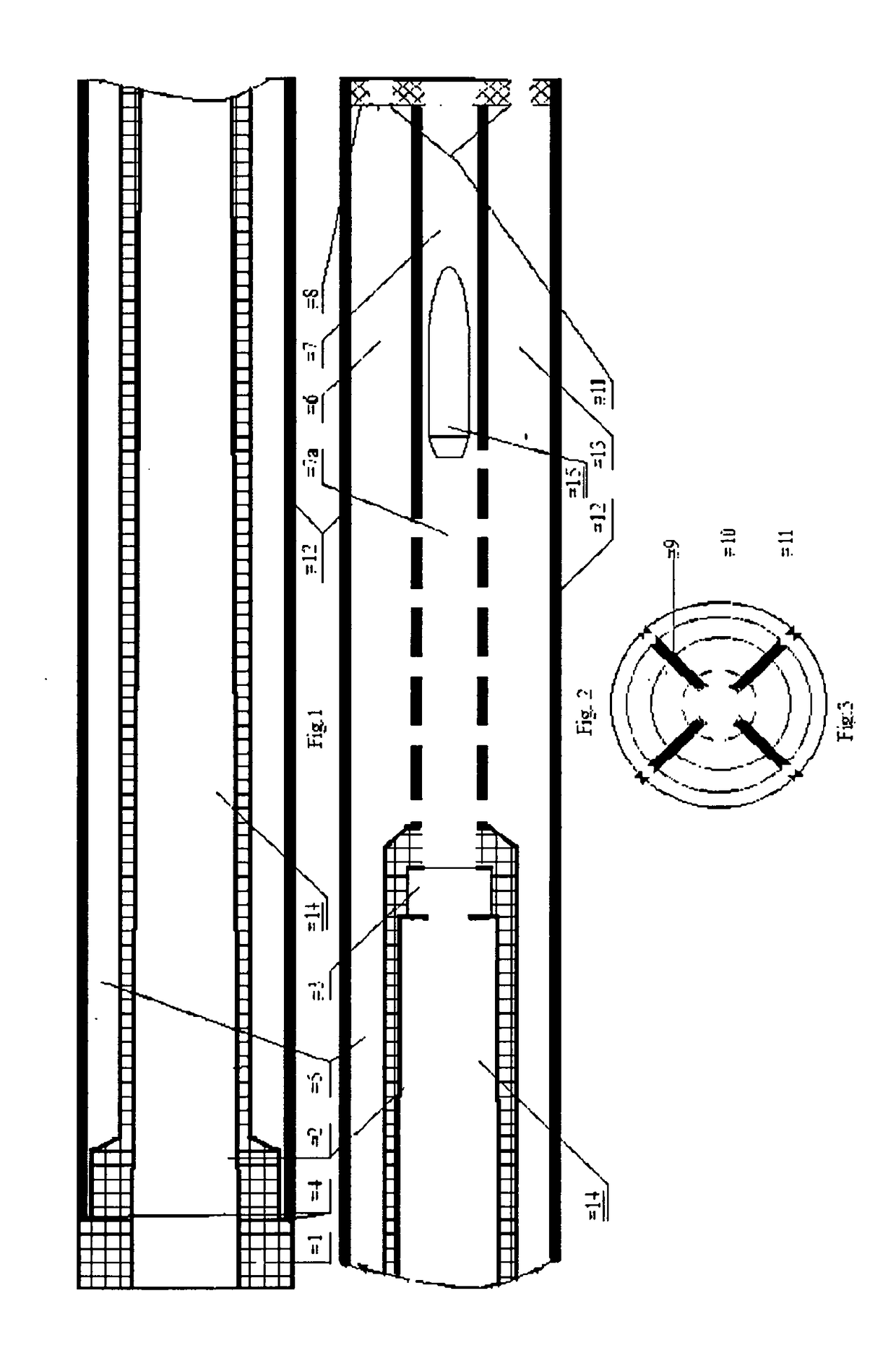

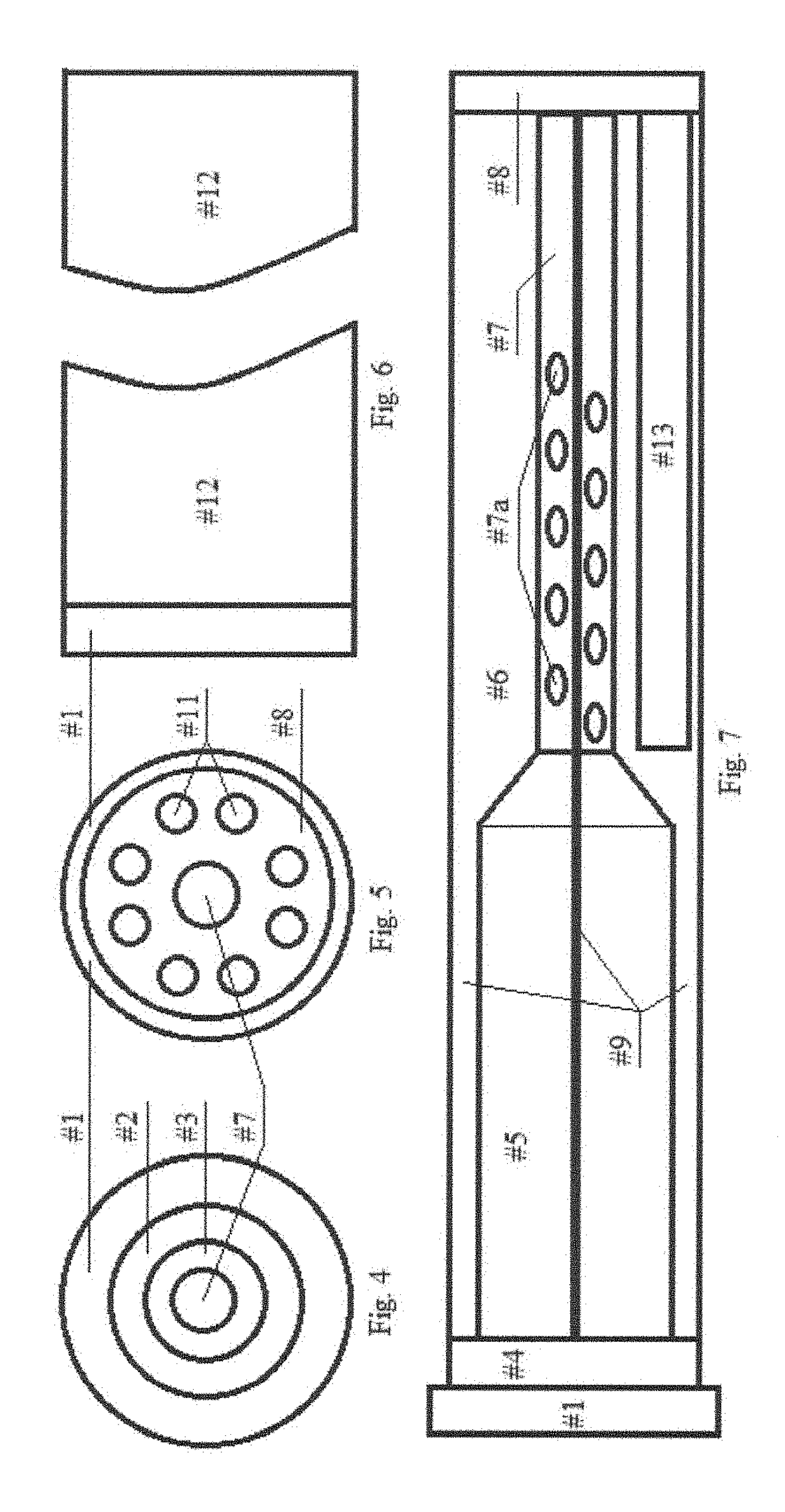

[0032]The present invention is a hooded muzzle brake flash suppressor for reducing recoil, noise, as well as the large muzzle flash, associated with many prior muzzle brake designs, during the discharge of a magnum level or other high power firearm. Referring initially to #1, a first embodiment of the present invention is shown. The invented hooded muzzle brake is made up of a flame, heat and pressure resistant cylindrical bo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap