Liquid ejecting head and liquid ejecting apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Embodiment 1

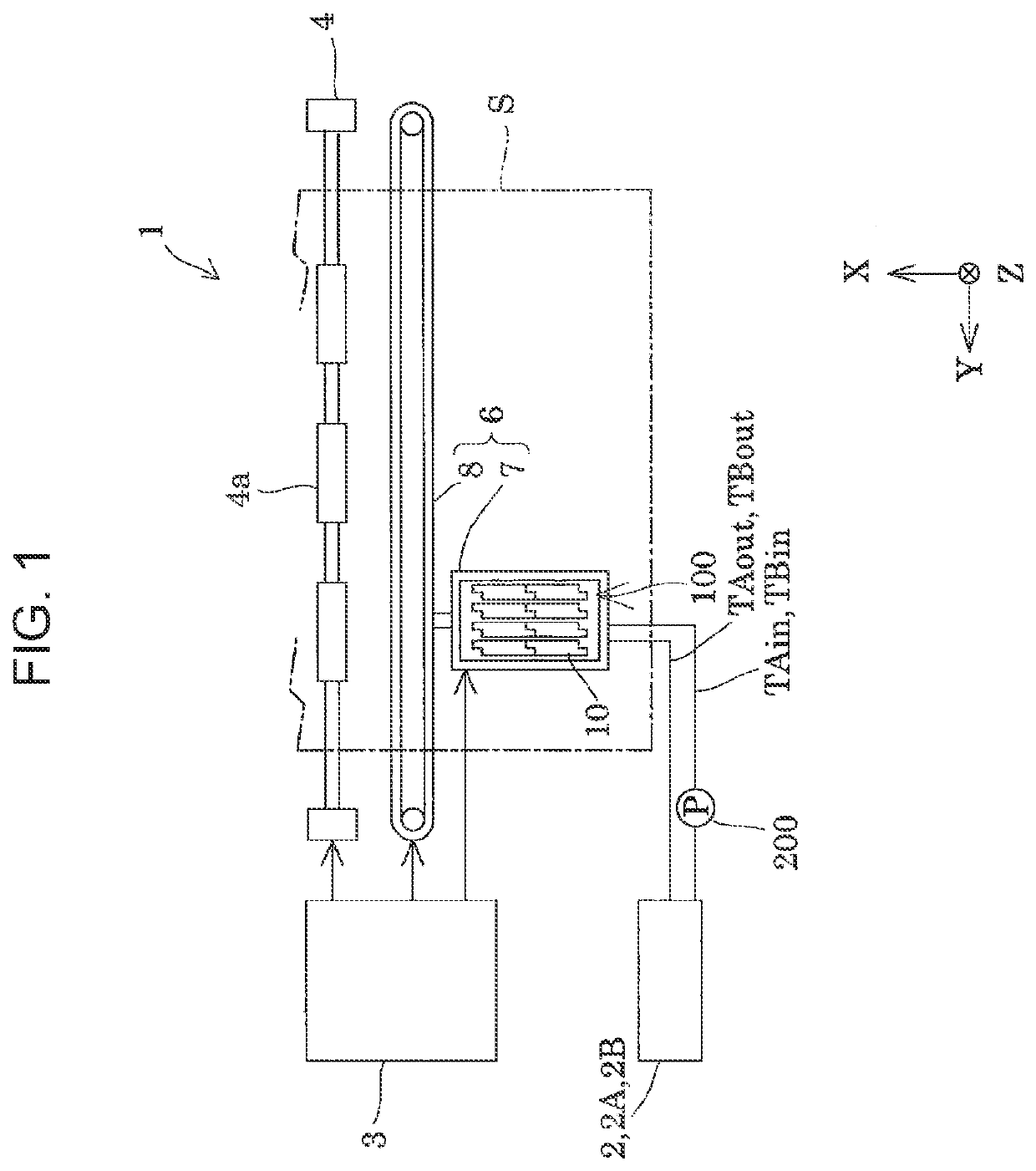

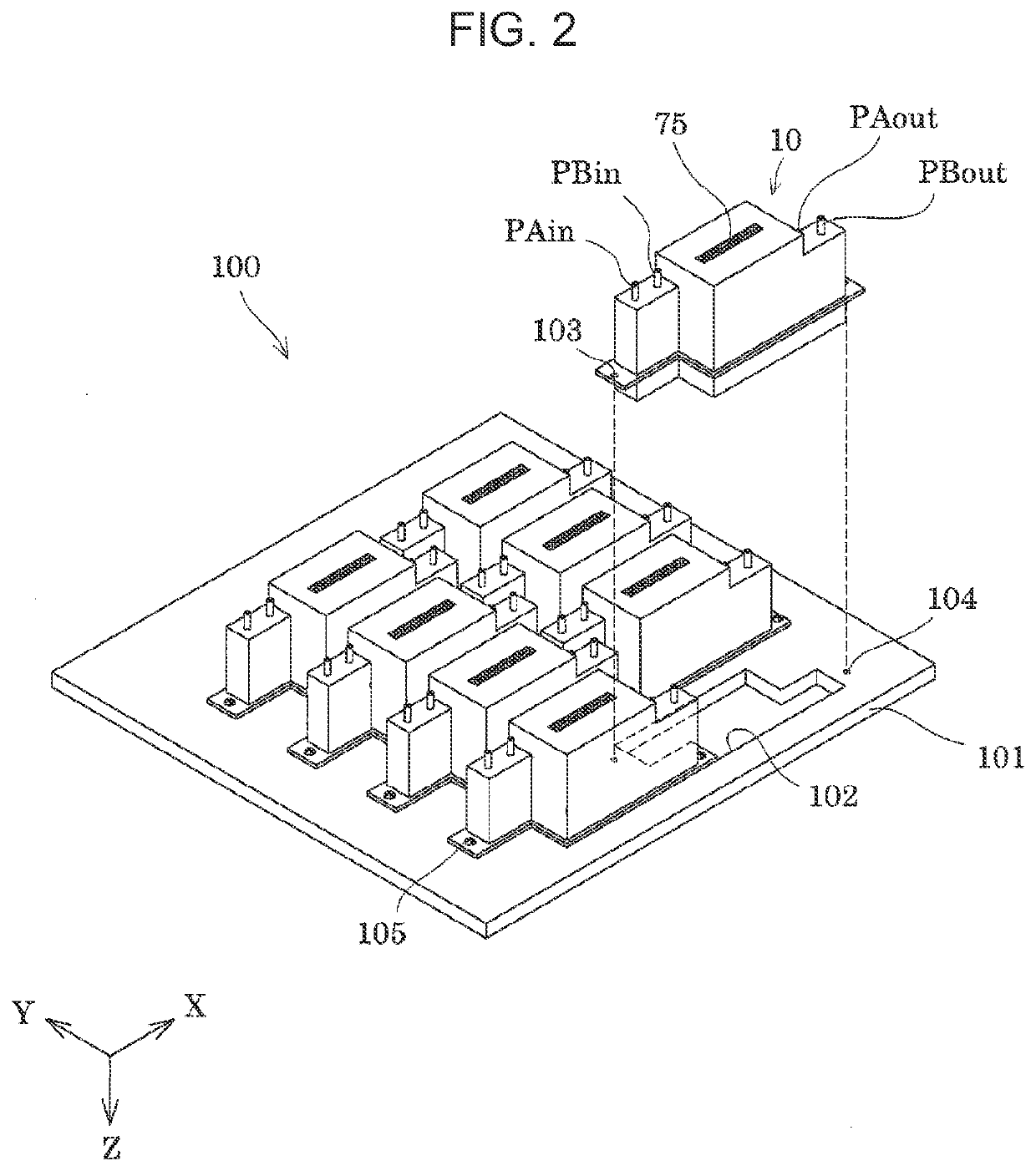

[0035]FIG. 1 is a view illustrating a schematic configuration of an ink jet type recording apparatus 1 which is an example of a “liquid ejecting apparatus” according to Embodiment 1 of the present disclosure.

[0036]As illustrated in FIG. 1, the ink jet type recording apparatus 1 which is an example of the liquid ejecting apparatus is a printing apparatus that performs printing of an image or the like by arranging dots formed on a medium S by ejecting and landing ink, which is a type of liquid, as ink droplets on the medium S, such as a printing paper sheet. As the medium S, any material such as a resin film or cloth can be used in addition to a recording paper sheet.

[0037]The ink jet type recording apparatus 1 includes a head module 100 including an ink jet type recording head 10 (hereinafter, also simply referred to as a recording head 10) which is an example of a “liquid ejecting head”, a liquid container 2, a control unit 3 which is a control section, a transport mechanis

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap