Submerged processing device for photosensitive material

a processing device and material technology, applied in the direction of photosensitive materials, printers, instruments, etc., can solve the problems of poor efficiency of stirring the processing liquid stored therein, the difficulty of making the processing of photosensitive materials more rapid, and the increase of the manufacturing cost of the processing device, so as to improve the efficiency and the performance of processing, shorten the conveying path, and increase the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

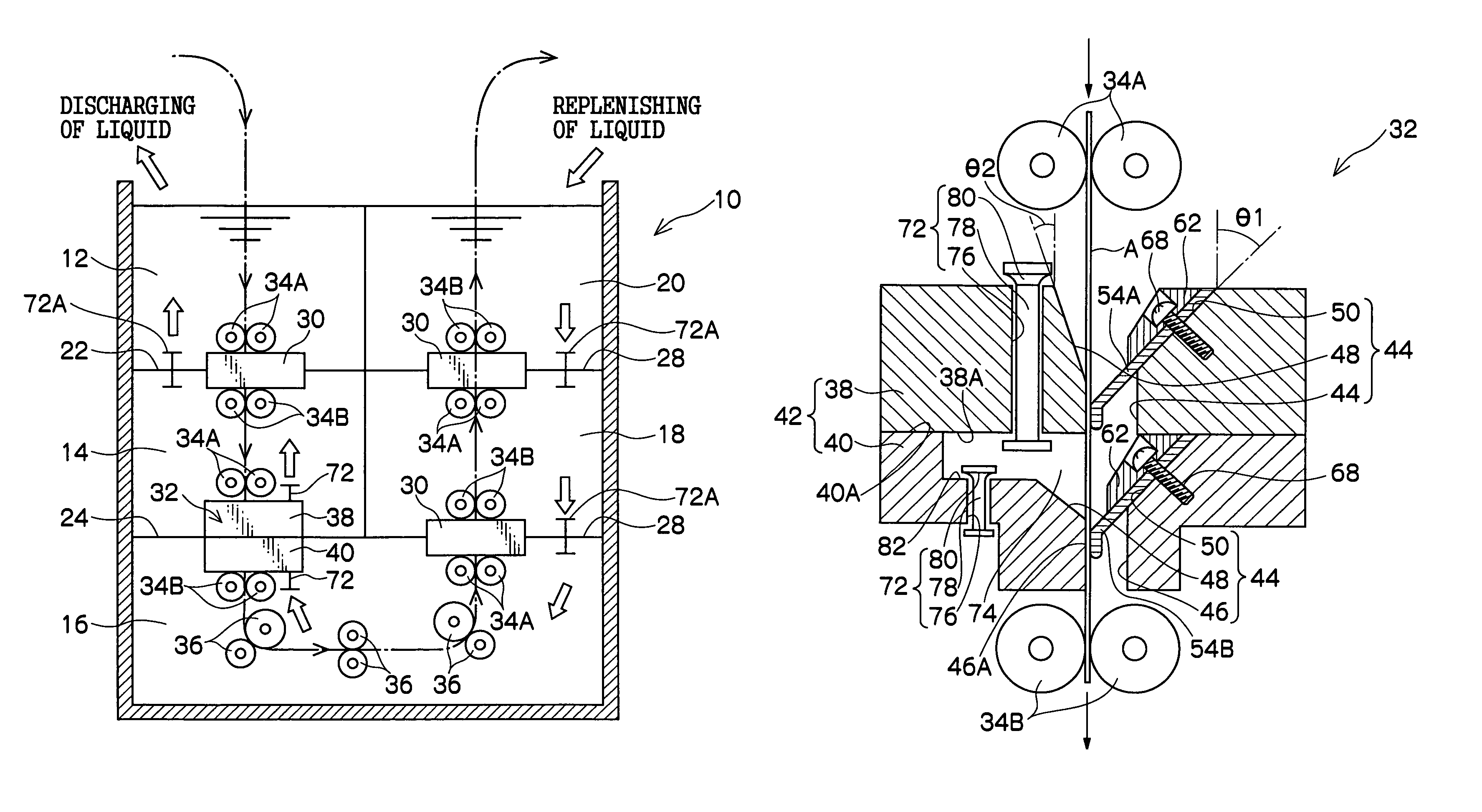

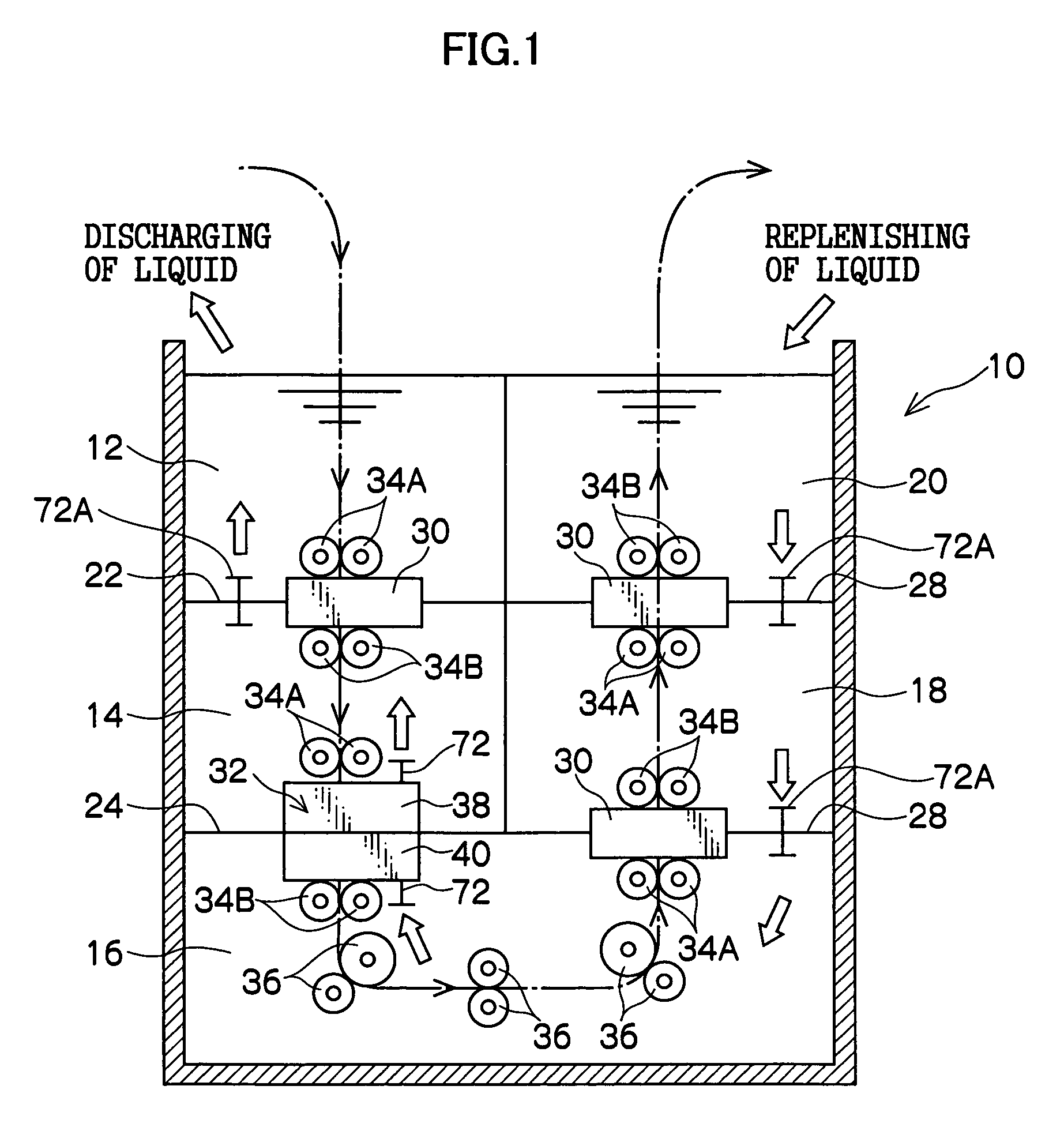

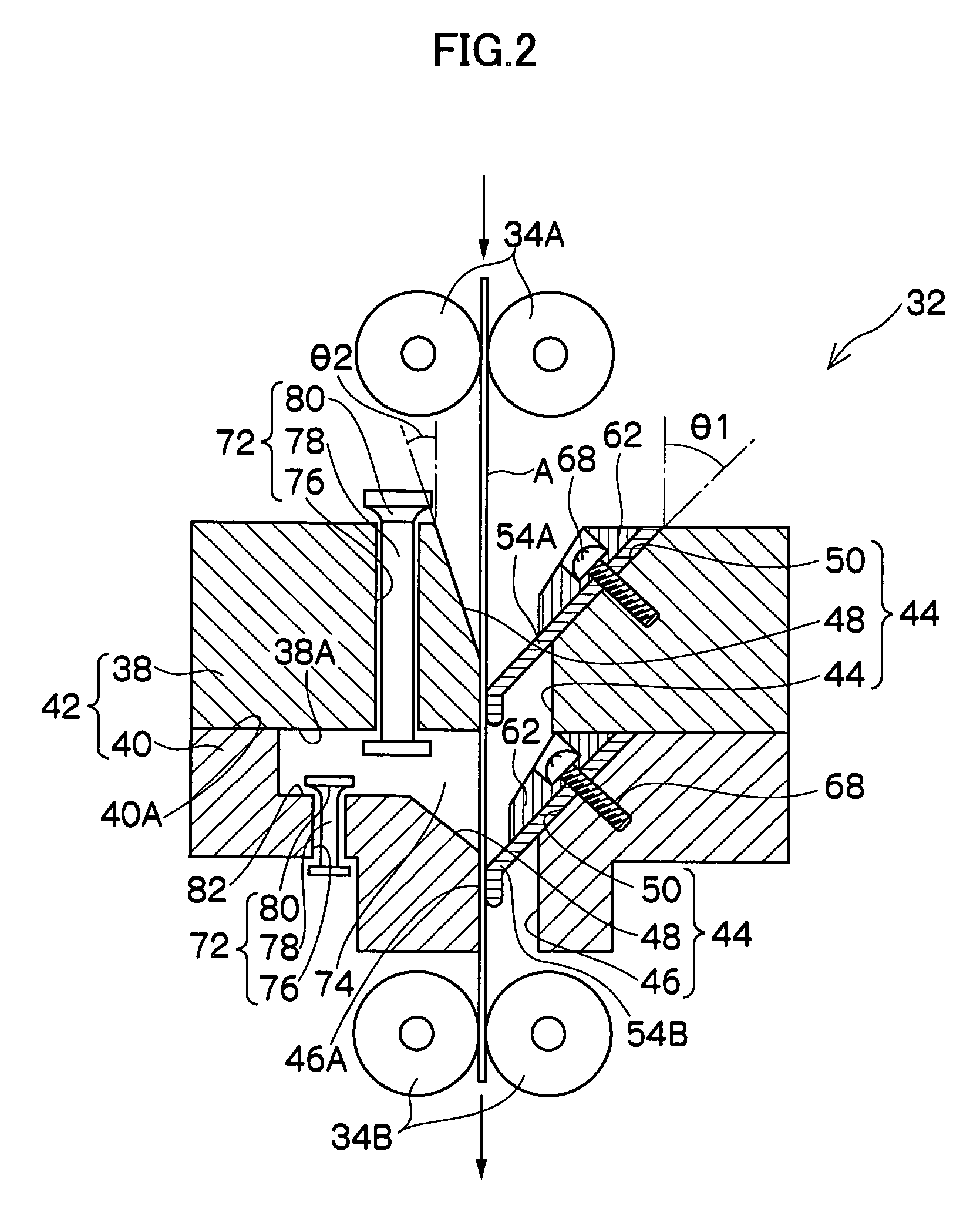

[0052]A submerged processing device for a photosensitive material relating to an embodiment of the present invention will be described with reference to FIGS. 1 through 16.

[0053]A processing tank main body 10 shown in FIG. 1 is structured as a processing tank which carries out washing and stabilizing processing and which is provided immediately after an unillustrated developing tank and an unillustrated fixing / bleaching tank, at a photosensitive material processing device (automatic developing device) which develops photosensitive materials (e.g., color prints or the like). A predetermined amount of wash water, which serves as a processing liquid (or processing solution), is stored within the processing tank main body 10.

[0054]Five processing chambers (processing tanks), which are a first processing chamber 12, a second processing chamber 14, a third processing chamber 16, a fourth processing chamber 18, and a fifth processing chamber 20, are provided so as to be partitioned off from

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap