Torque reaction control jig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In the following description, the various sides and surfaces of the alignment jig of the present invention are described as they are presented in the drawings. Accordingly, the use of the directional references (i.e., upper, lower, lateral side, etc.,) is only to be construed as they relate to the orientation of the jig in the drawings. Insofar as the jig is capable of use in various orientations, these directional references are not to be construed in a limiting fashion.

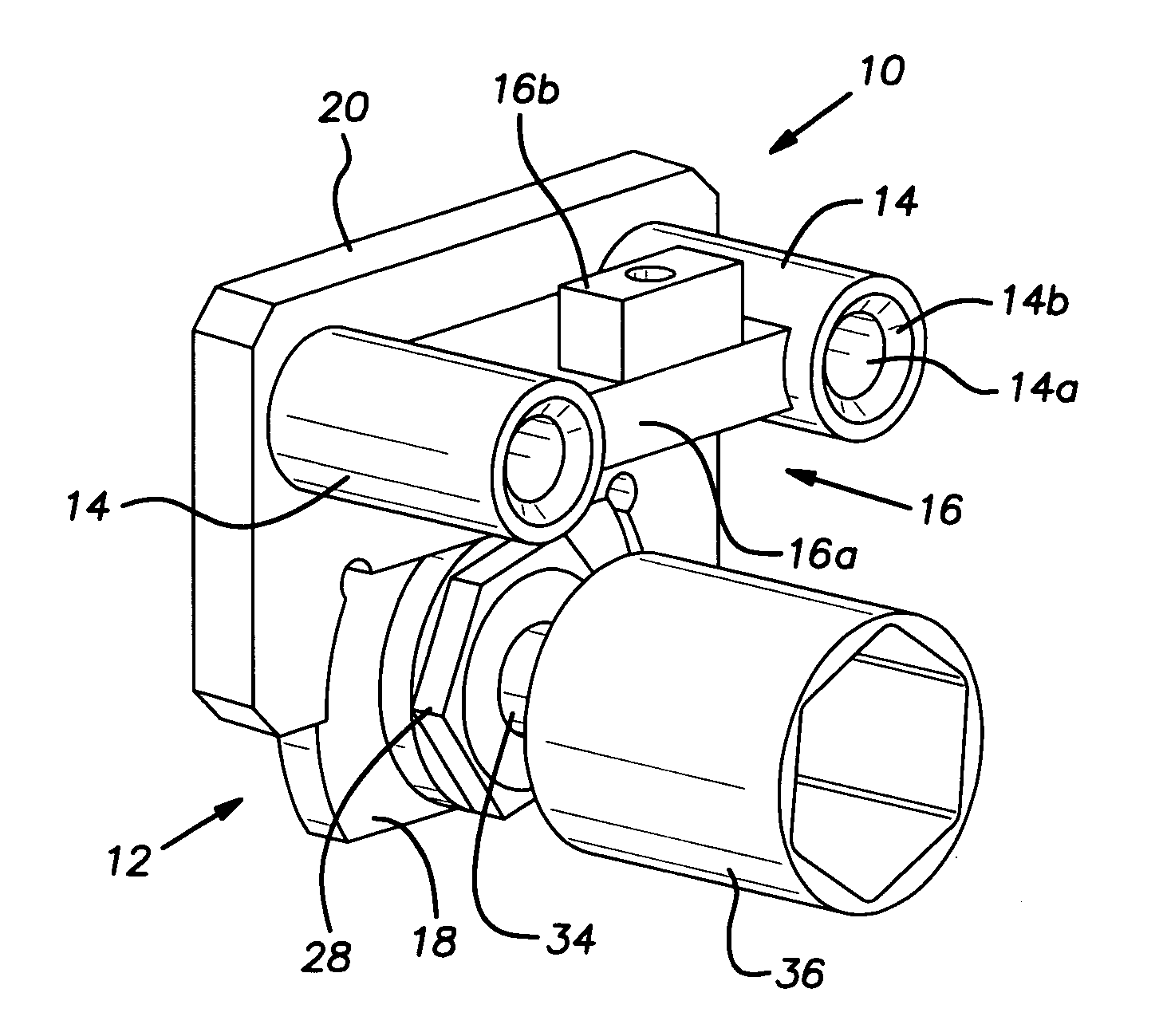

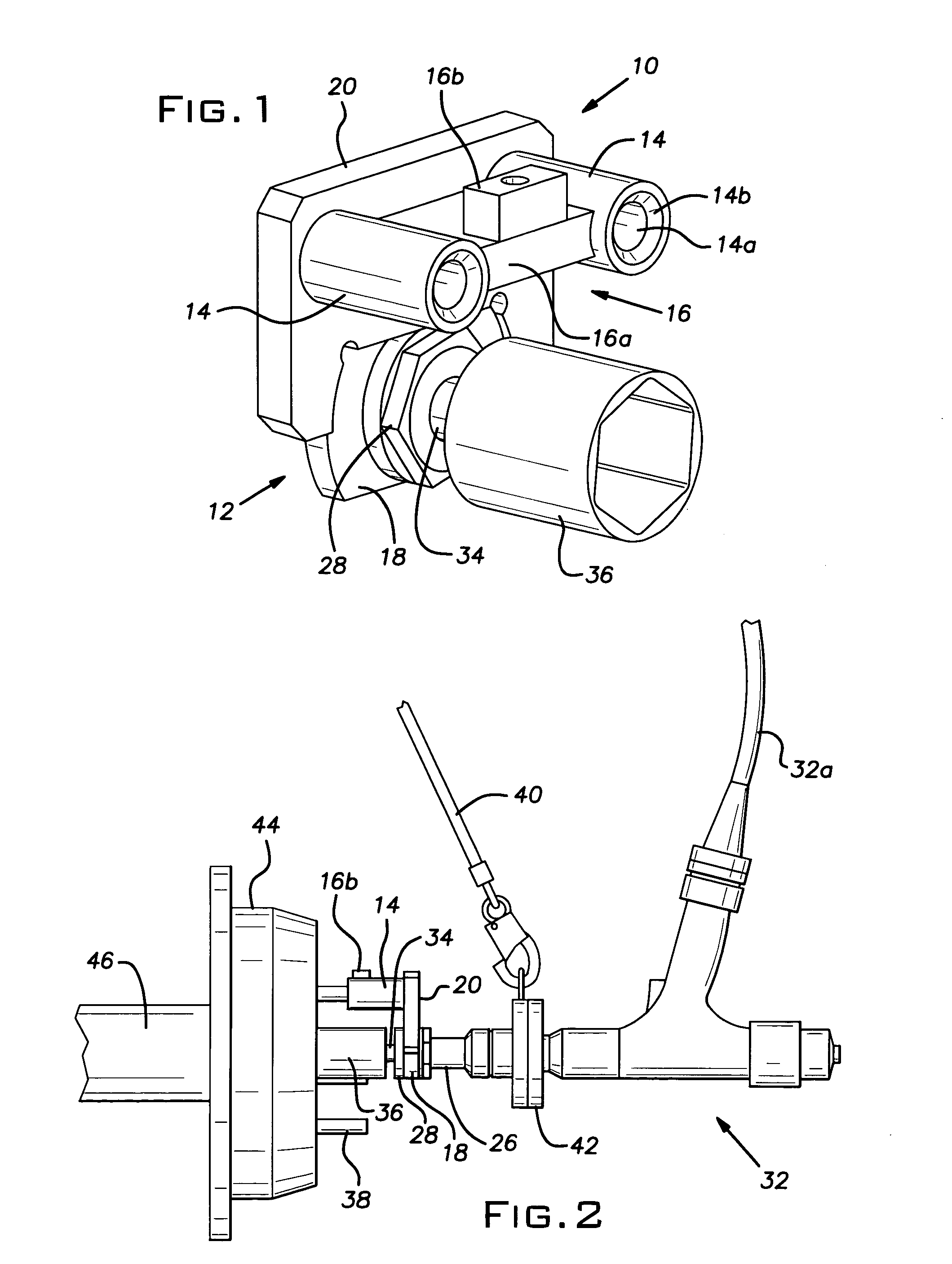

[0018]With reference to FIGS. 1–3, the torque reaction control jig 10 of the present invention includes a jig body 12, a pair of wheel stud receptacles or nests 14, and a barrier member 16. In the preferred and illustrated embodiment, the jig body 12 includes an adaptor body 18 that is affixed to an alignment body 20.

[0019]The adaptor body 18 has a generally rectangular peripheral shape, albeit with curved or arcuate lateral sides, and is partially received within a similarly shaped, downwardly facing recess form

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap