Product transfer assembly for a vending machine

a product transfer and vending machine technology, applied in the field of vending machines, can solve the problems that other products are not likely to capture the attention of consumers for a long time, and achieve the effects of reducing dislocation, enhancing excitement value, and improving control of downward travel of product items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

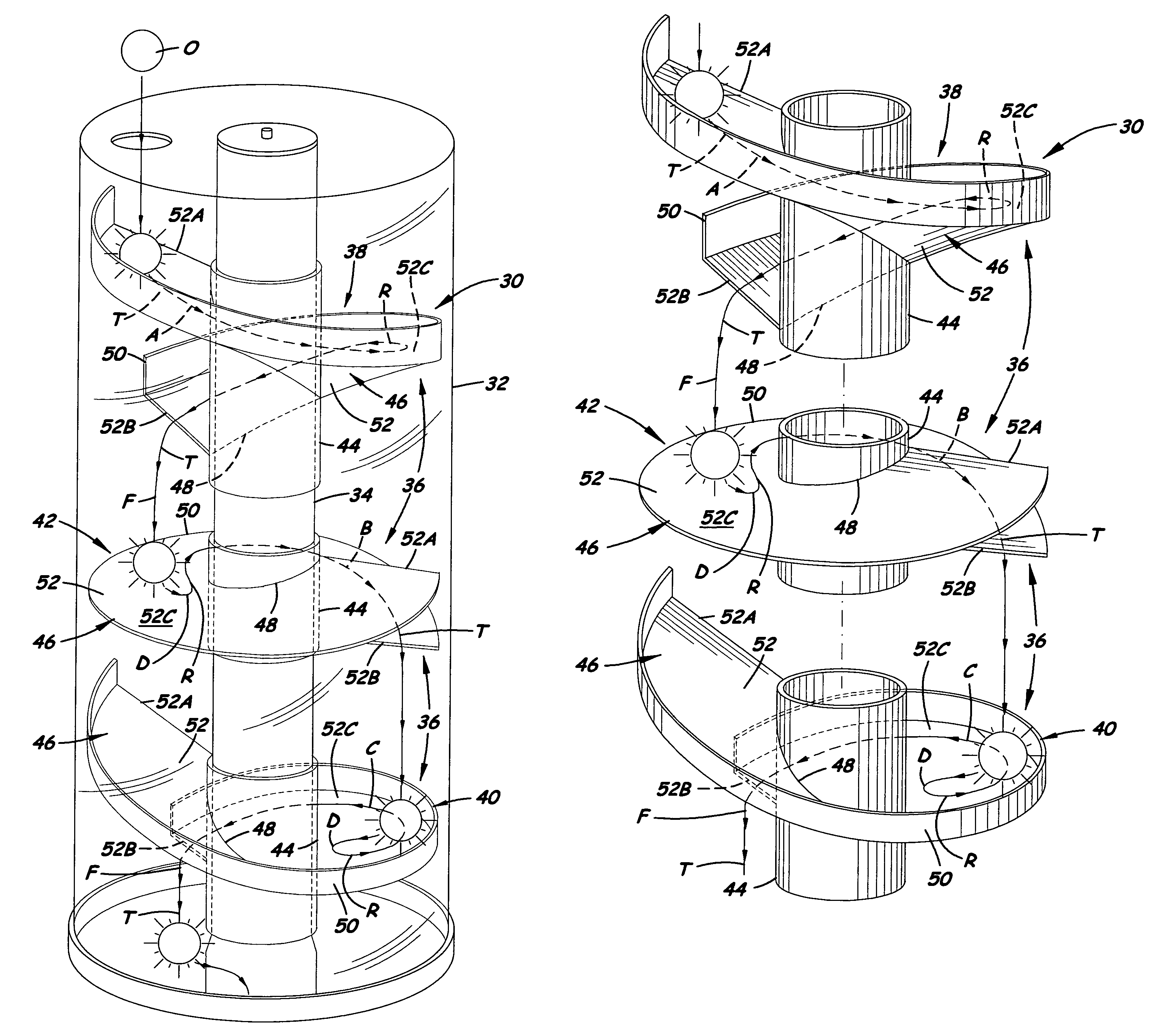

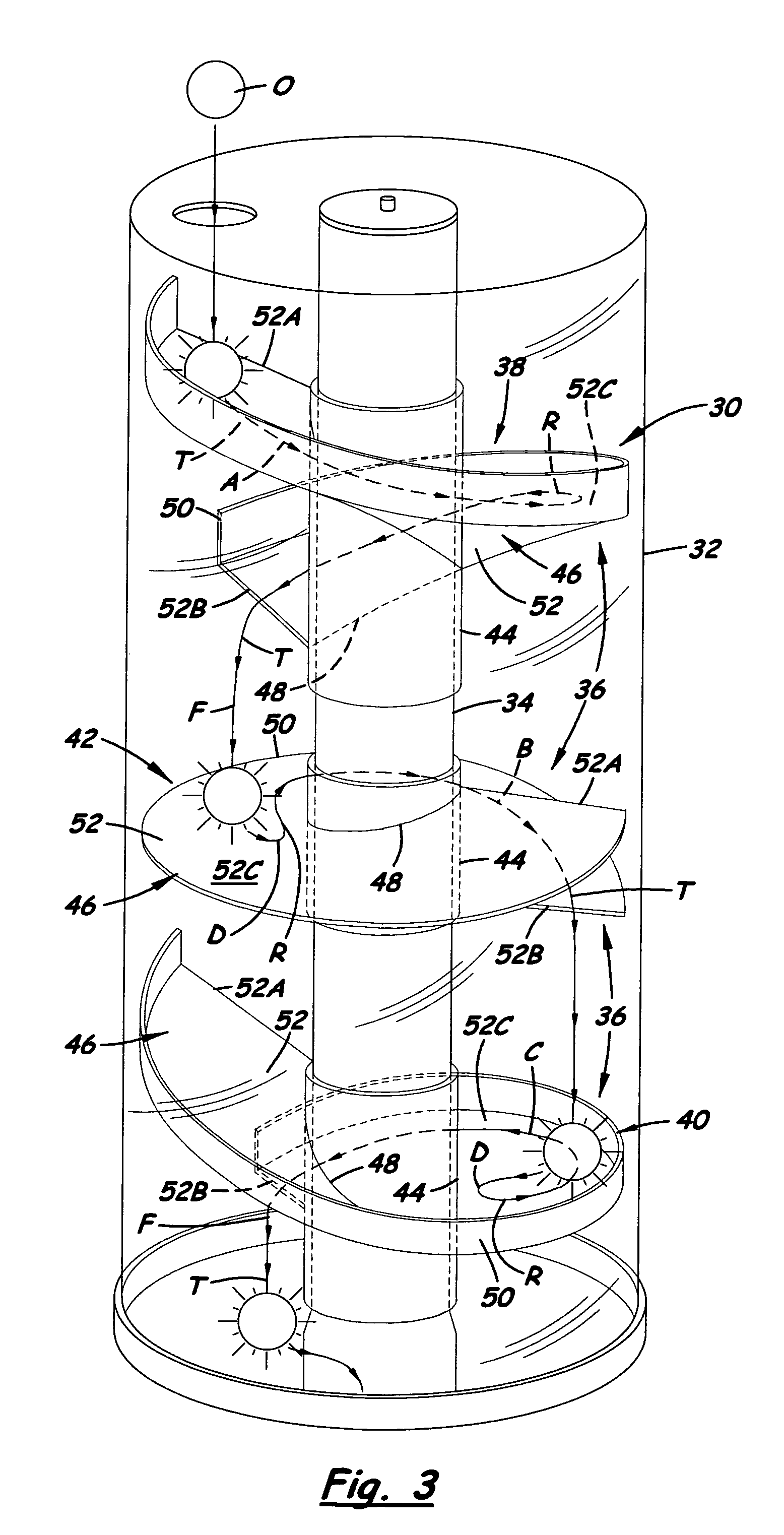

Embodiment Construction

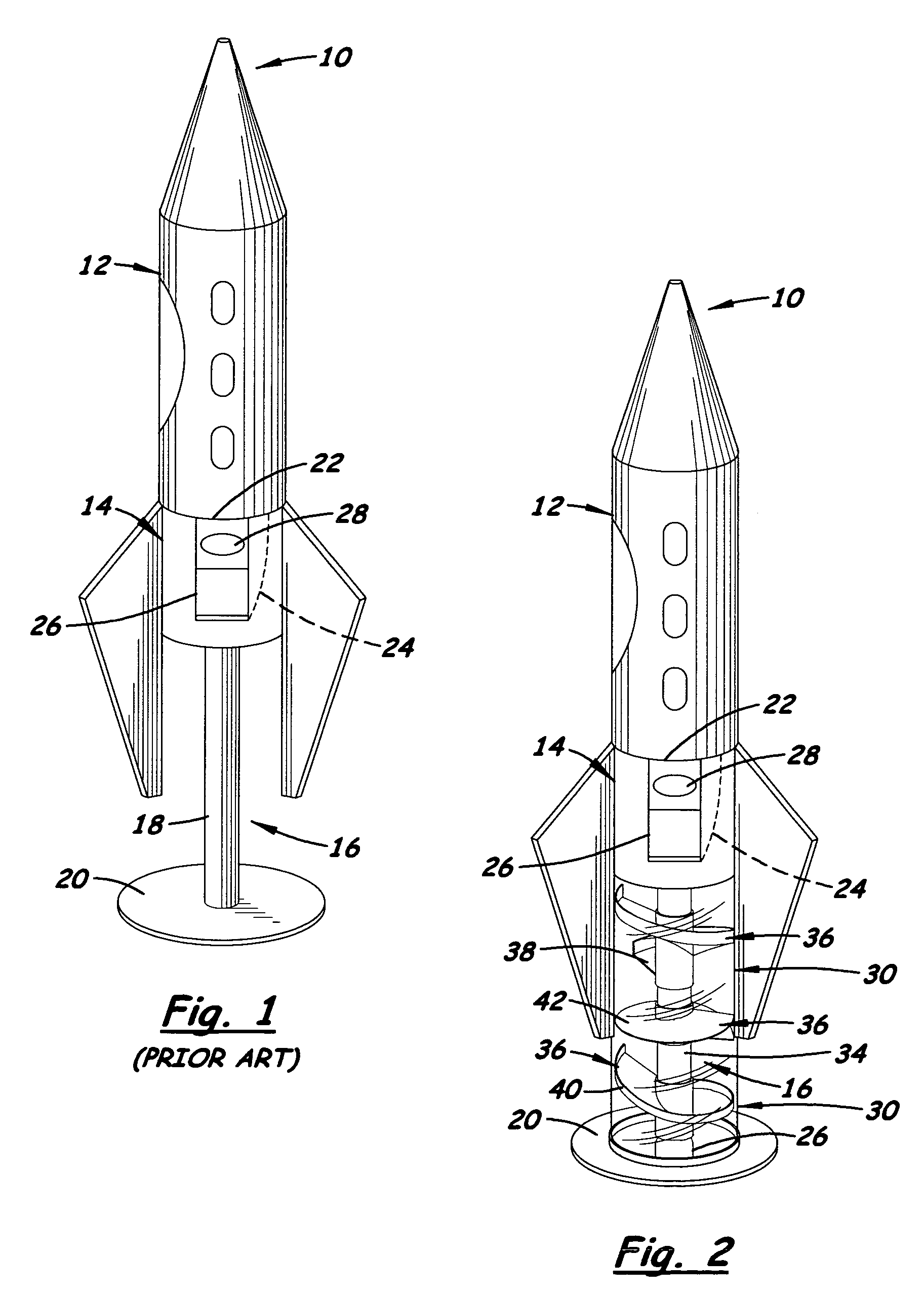

[0017]Referring to the drawings and particularly to FIG. 1, there is generally illustrated an exemplary embodiment of a prior art vending machine 10 in which the present invention may be advantageously incorporated as seen in FIG. 2. The prior art vending machine 10 basically includes a reservoir 12 for holding items of the product in a bulk form and a housing 14 supporting the reservoir 12 and, in turn, mounted on a stand 16 having an elongated tubular support member 18 and a flat base 20 fixedly attached to a lower end of the tubular support member 18 so as to maintain it in an upright orientation. The prior art vending machine 10 also includes a coin-actuated dispensing mechanism 22 mounted to and within the housing 14 and thus disposed below and in communication with the reservoir 12, and a discharge chute structure 24 mounted inside the housing 14 which communicates with the dispensing mechanism 22 and routes one or more product items to an exterior dispensing location 26 on the h

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap