Automatic transmission pump-priming device

a technology of automatic transmission and pump, which is applied in the direction of fluid couplings, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of engine stall on transmission engagement, slow torque converter charge at engine idle, and pump nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

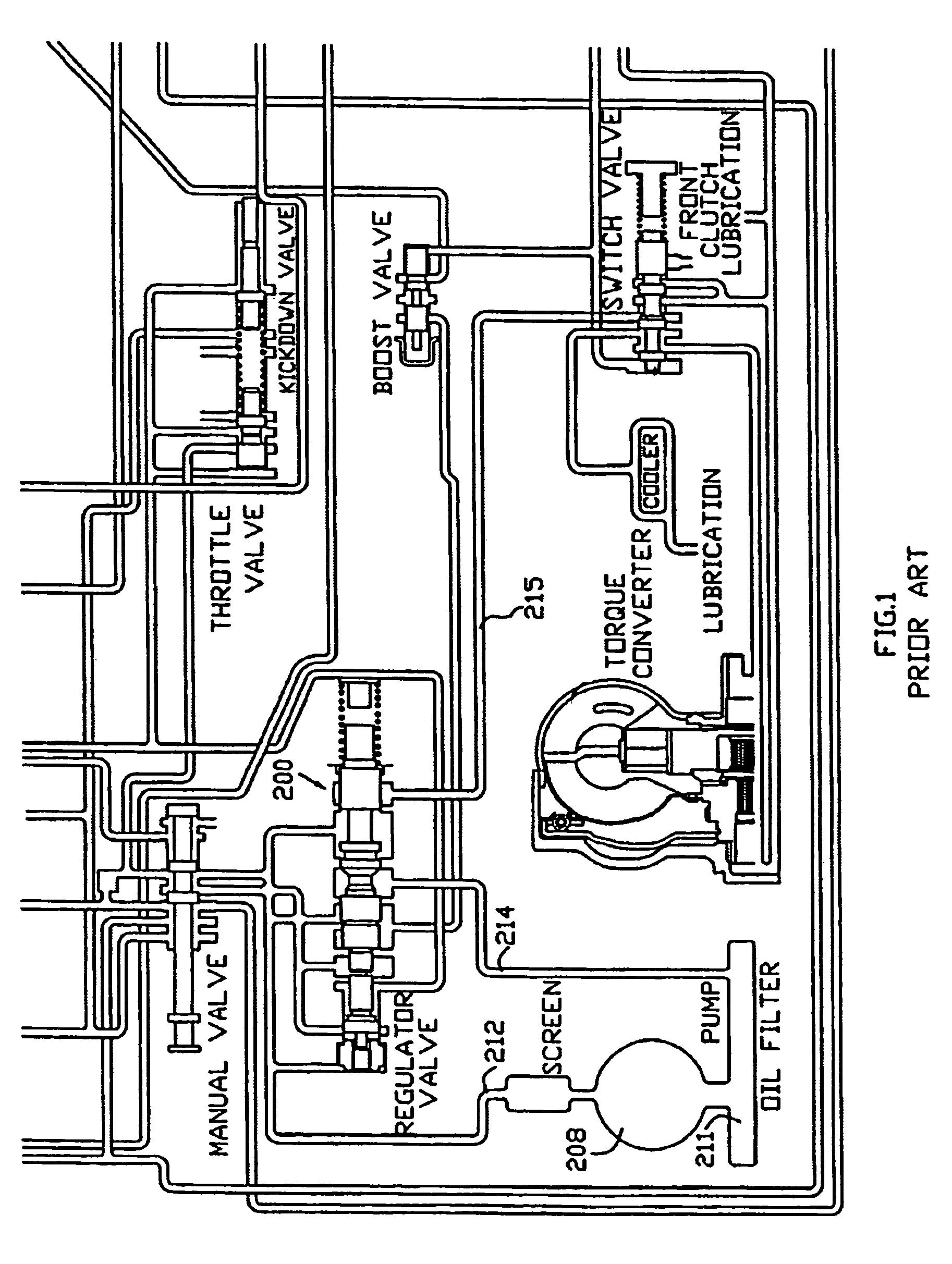

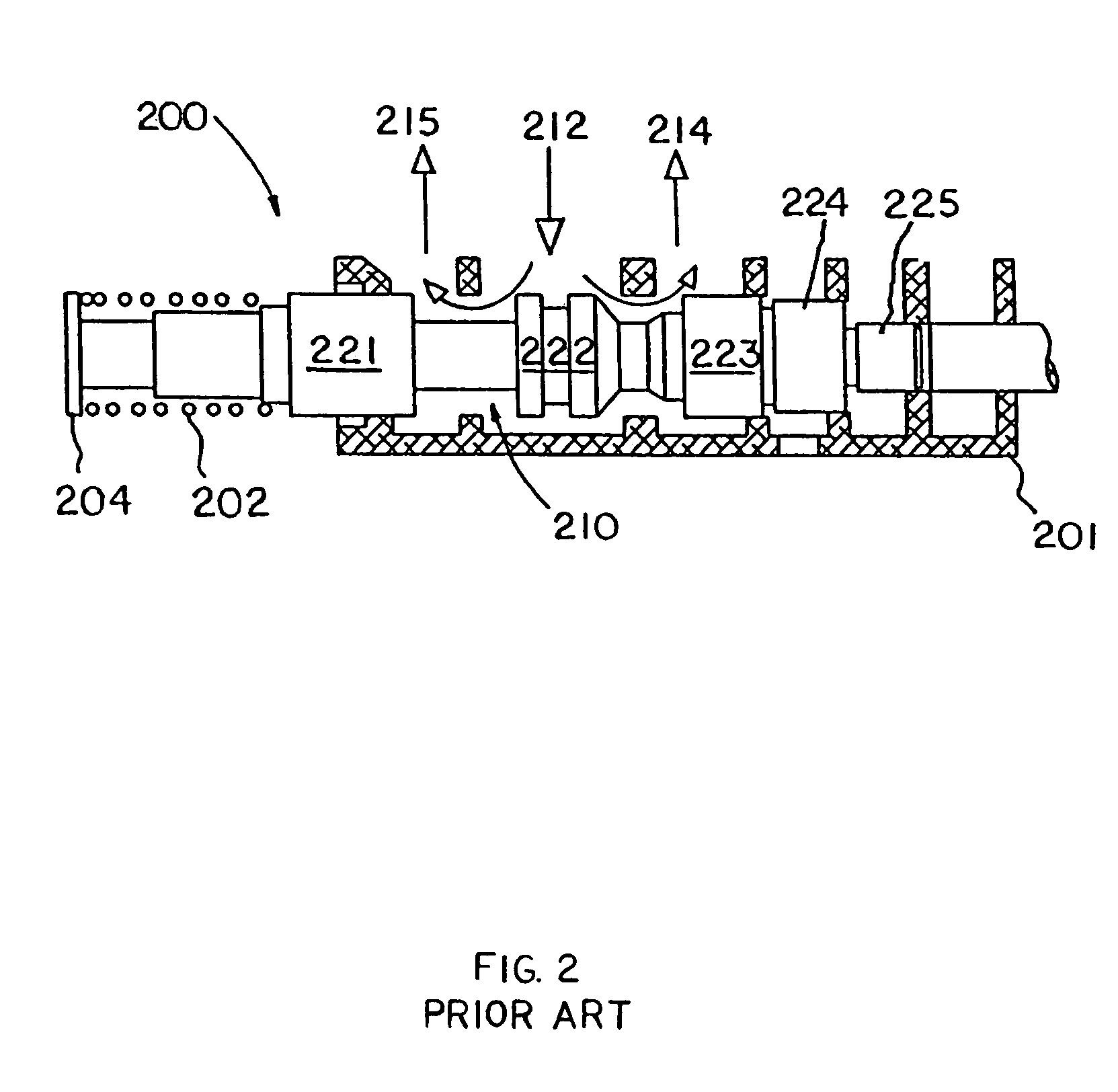

[0021]Prior to describing the present invention in detail it may be beneficial to briefly review the function of the pressure regulator valve and the ATF pump within the hydraulic system of the CHRYSLER transmissions. Referring to FIG. 1 there is shown a partial schematic of the hydraulic system of the aforementioned Chrysler transmissions wherein a pressure regulator valve, indicated generally at 200, is illustrated. The pressure regulator valve 200 is located within the valve body 201 (FIG. 2) of the transmission and regulates line pressure in relation to vehicle operating conditions. In operation ATF at line pressure (i.e. 160-270 psi) from the hydraulic pump 208 enters the pressure regulator valve 200 via pump output circuit 212. The pressure regulator valve 200 routes ATF into both the converter charge circuit 215 and the sump return circuit 214 as shown in FIG. 1 depending on engine speed and operating conditions.

[0022]As seen more clearly in FIG. 2, the pressure regulator valve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap