Multi-sectional bobbin for high voltage inductor or transformer

a transformer and multi-sectional technology, applied in the direction of transformer/inductance details, coils, electrical equipment, etc., can solve the problems of insufficient insulation layer of transformer (or inductor) wire, inability to resist electrical breakdown, and tend to interfere with mass production, so as to prevent wire slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

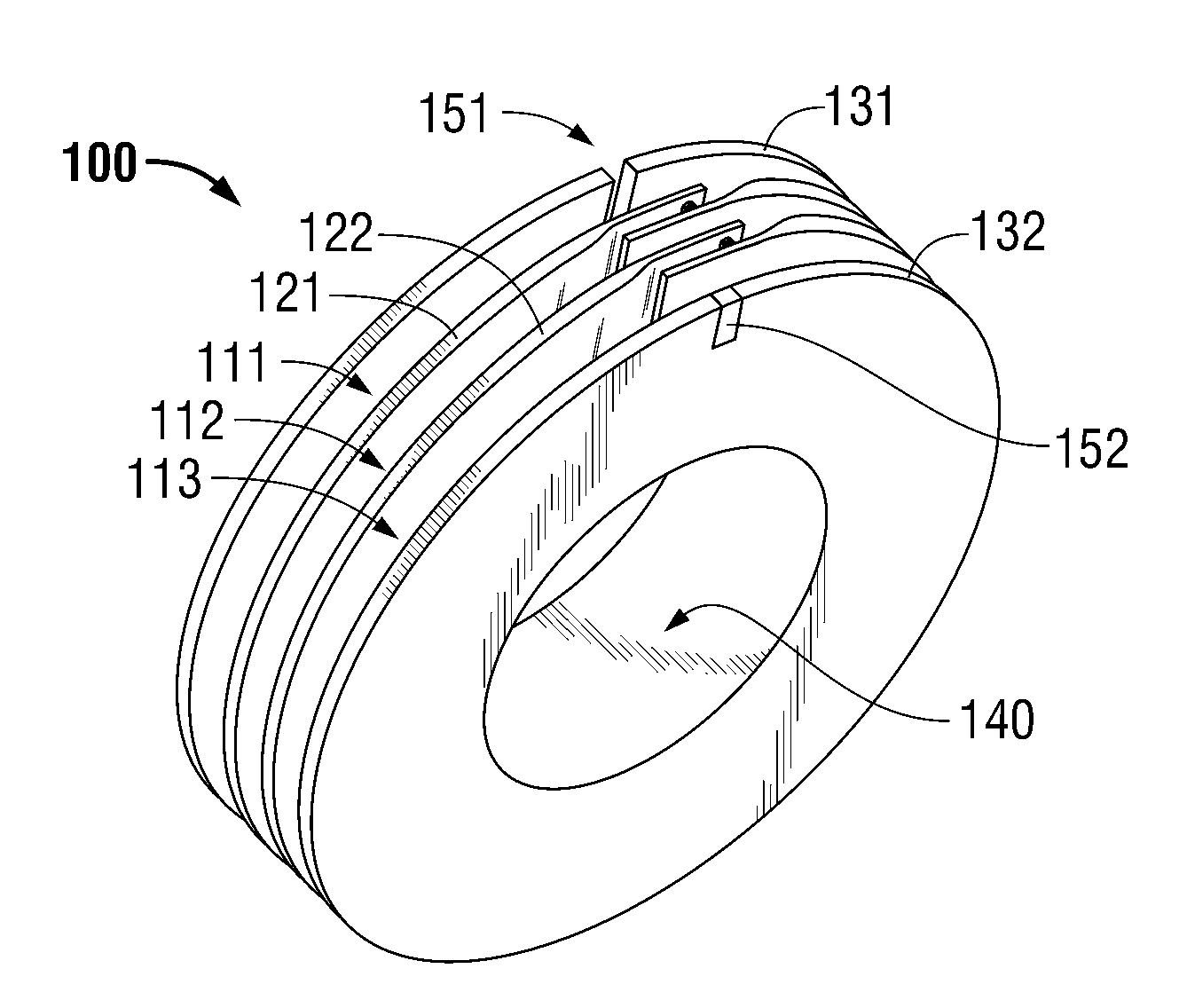

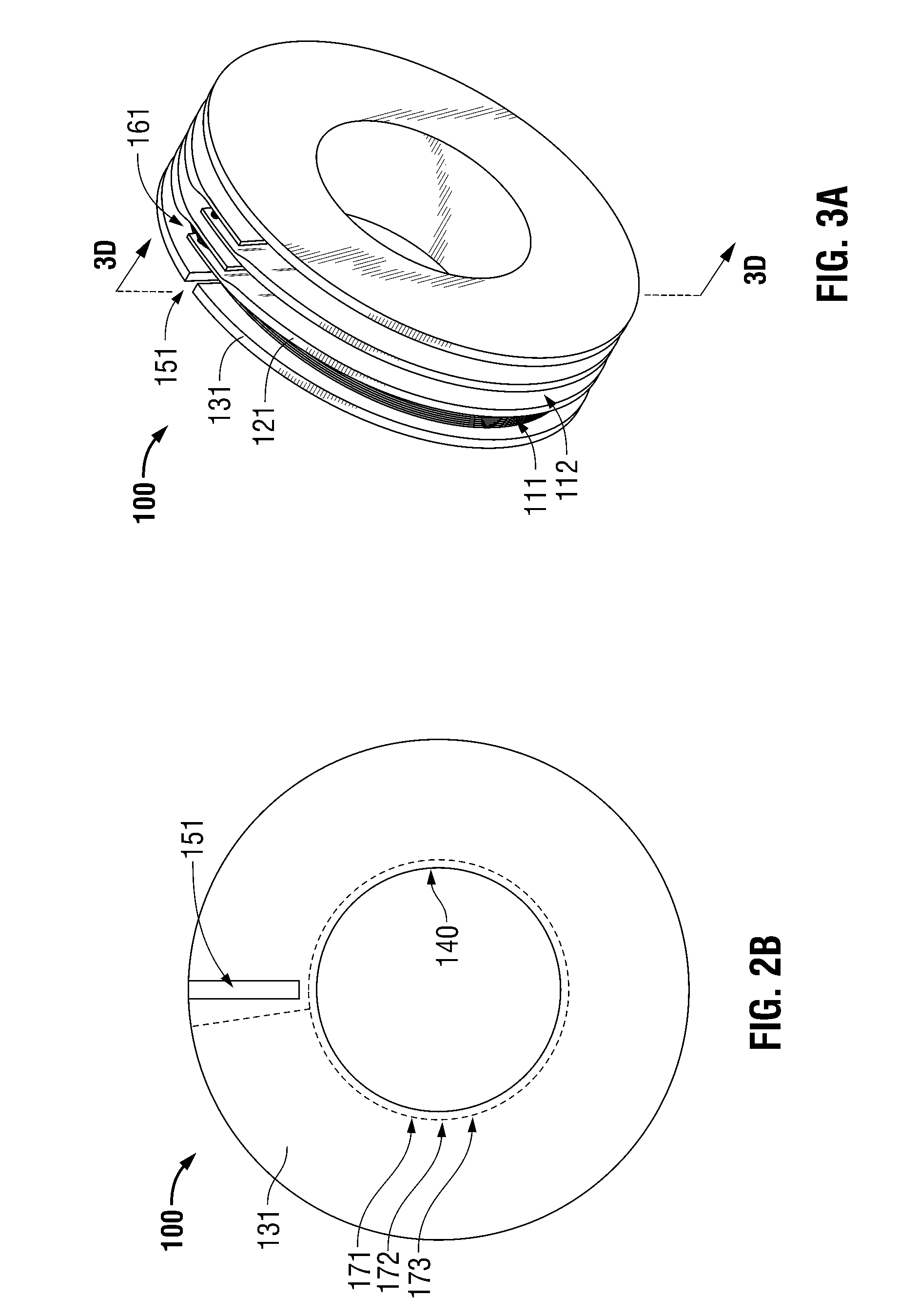

[0026]Inductors, coils and transformers are widely used in electric designs and systems. Typically, wire or some other conductor is wound around a spindle or winding form, hereinafter referred to as a “bobbin” in order to impart desired structure to the windings and, often, to facilitate alignment of such windings with a core. Persons of ordinary skill in the art will appreciate a wide variety of bobbin configurations, geometries, material selections, conductors, core configurations, etc. and this description does not attempt to inventory the substantial diversity of such variations. Instead, in the interests of conciseness and specificity with respect to certain inventive aspects, the present description focuses on exemplary embodiments in which a circular multi-sectional bobbin is wound (or windable) with wire in configurations typical (or at least illustrative) of coils employed in compact, small-form factor, high-voltage transformers. Based on that description context, persons of o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap