Tire for driving on ice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

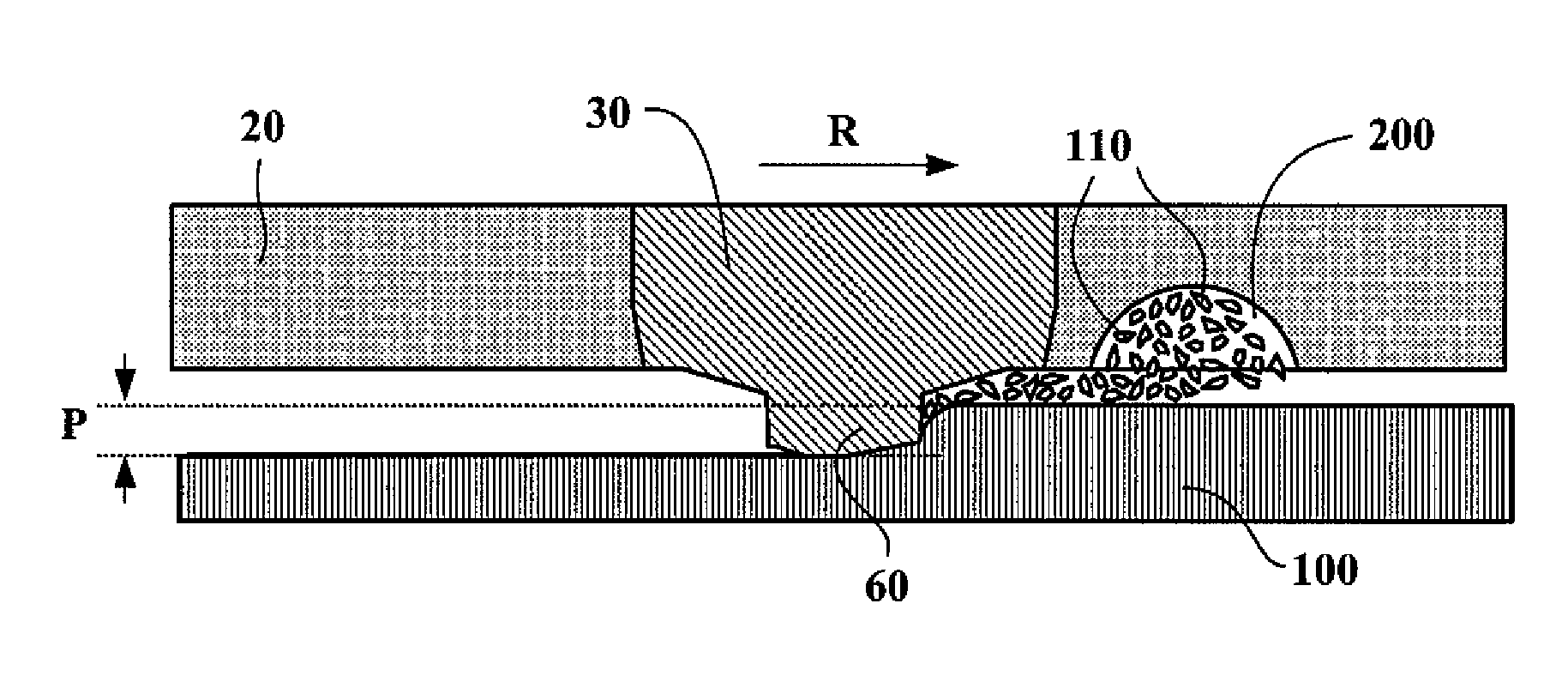

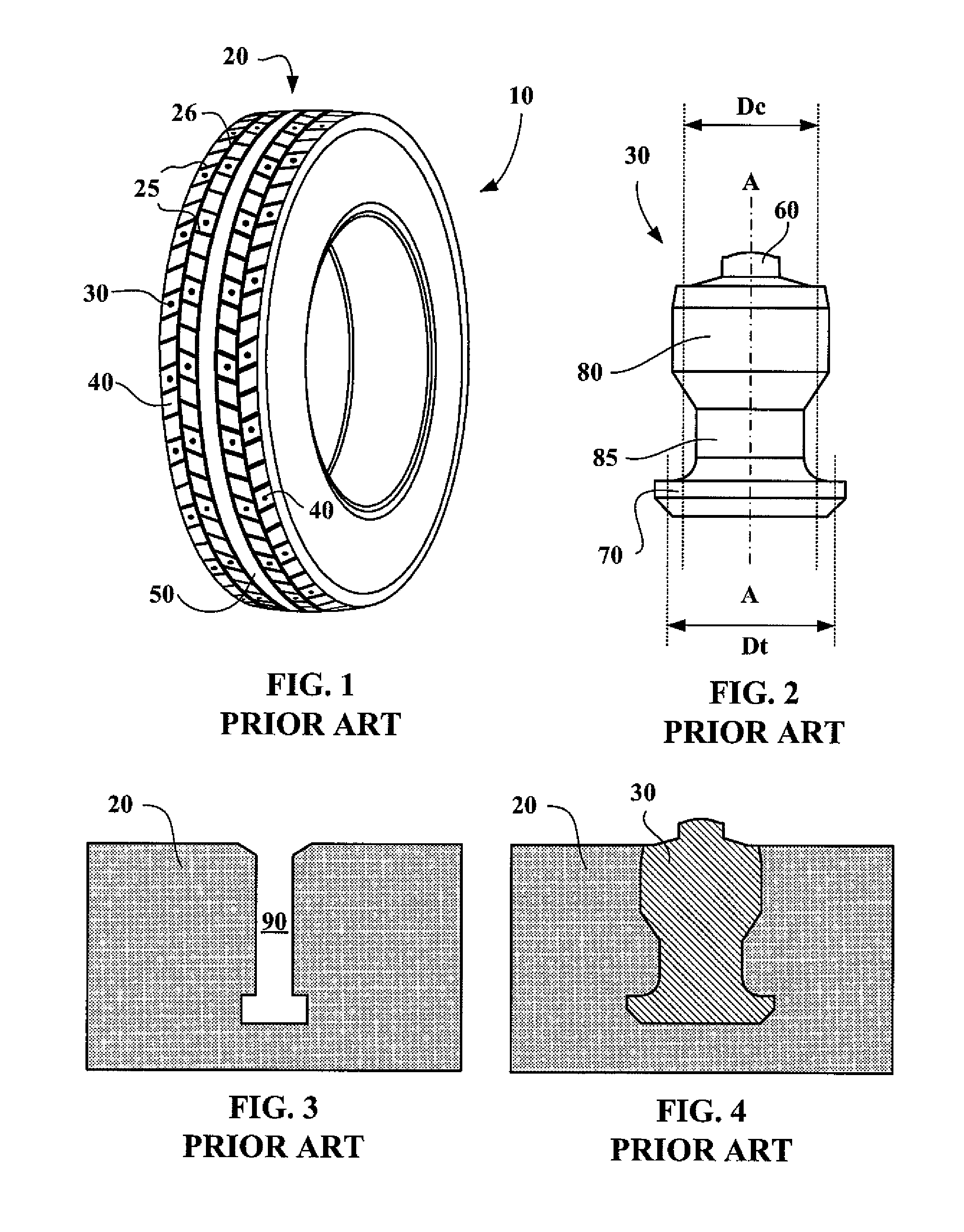

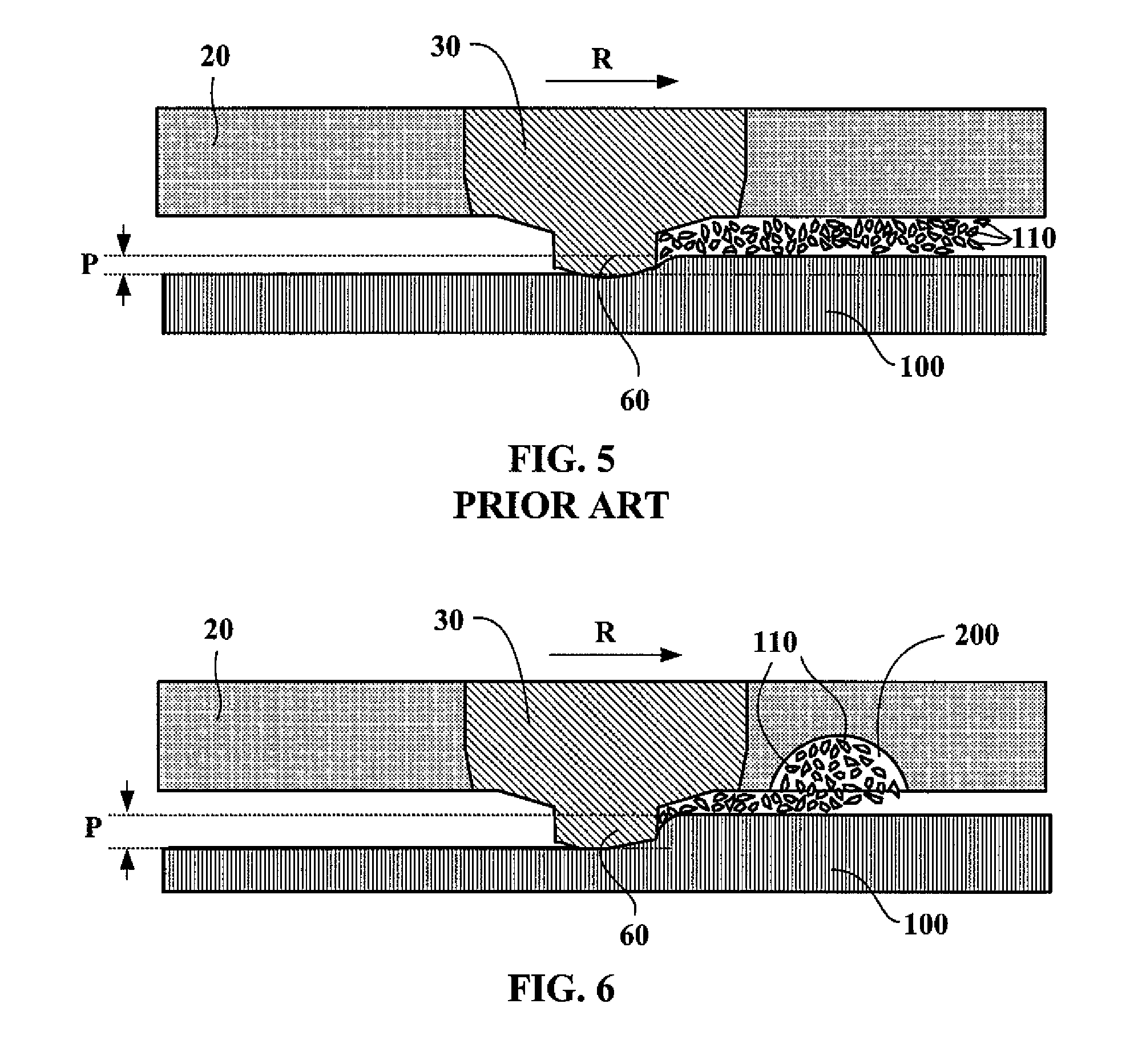

DETAILED DESCRIPTION OF THE DRAWINGS

[0035]The term “tire” here denotes any type of elastic tire whether or not in service it is subjected to an internal inflation pressure.

[0036]The term “groove” designates a cut-out in the tire tread that opens onto the rolling surface and the function of which is to evacuate water that has accumulated between the tire and the surface on which the tire rolls. Grooves may be circumferential or transverse. Typically, in a passenger car tire, they have a width of between 2 and 10 mm and a depth of about 8 mm. Grooves are distinguished from sipes in that sipes are much narrower (typically 0.3 to 1.5 mm) than grooves.

[0037]The term “stud” as used in this document is synonymous with the term “spike” also used in the prior art.

[0038]The term “recess” here denotes a hollow made in the rolling surface, the mean radial depth of which is greater than or equal to 1 mm.

[0039]The term “cavity” here denotes a cavity in the tread which does not directly open onto the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap