Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1 results about "Gravity separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: i.e. the components of the mixture have different specific weight. All of the gravitational methods are common in the sense that they all use gravity as the dominant force. One type of gravity separator lifts the material by vacuum over an inclined vibrating screen covered deck. This results in the material being suspended in air while the heavier impurities are left behind on the screen and are discharged from the stone outlet. Gravity separation is used in a wide variety of industries, and can be most simply differentiated by the characteristics of the mixture to be separated - principally that of 'wet' i.e. - a suspension versus 'dry' -a mixture of granular product. Often other methods are applied to make the separation faster and more efficient, such as flocculation, coagulation and suction. The most notable advantages of the gravitational methods are their cost effectiveness and in some cases excellent reduction. Gravity separation is an attractive unit operation as it generally has low capital and operating costs, uses few if any chemicals that might cause environmental concerns and the recent development of new equipment enhances the range of separations possible.

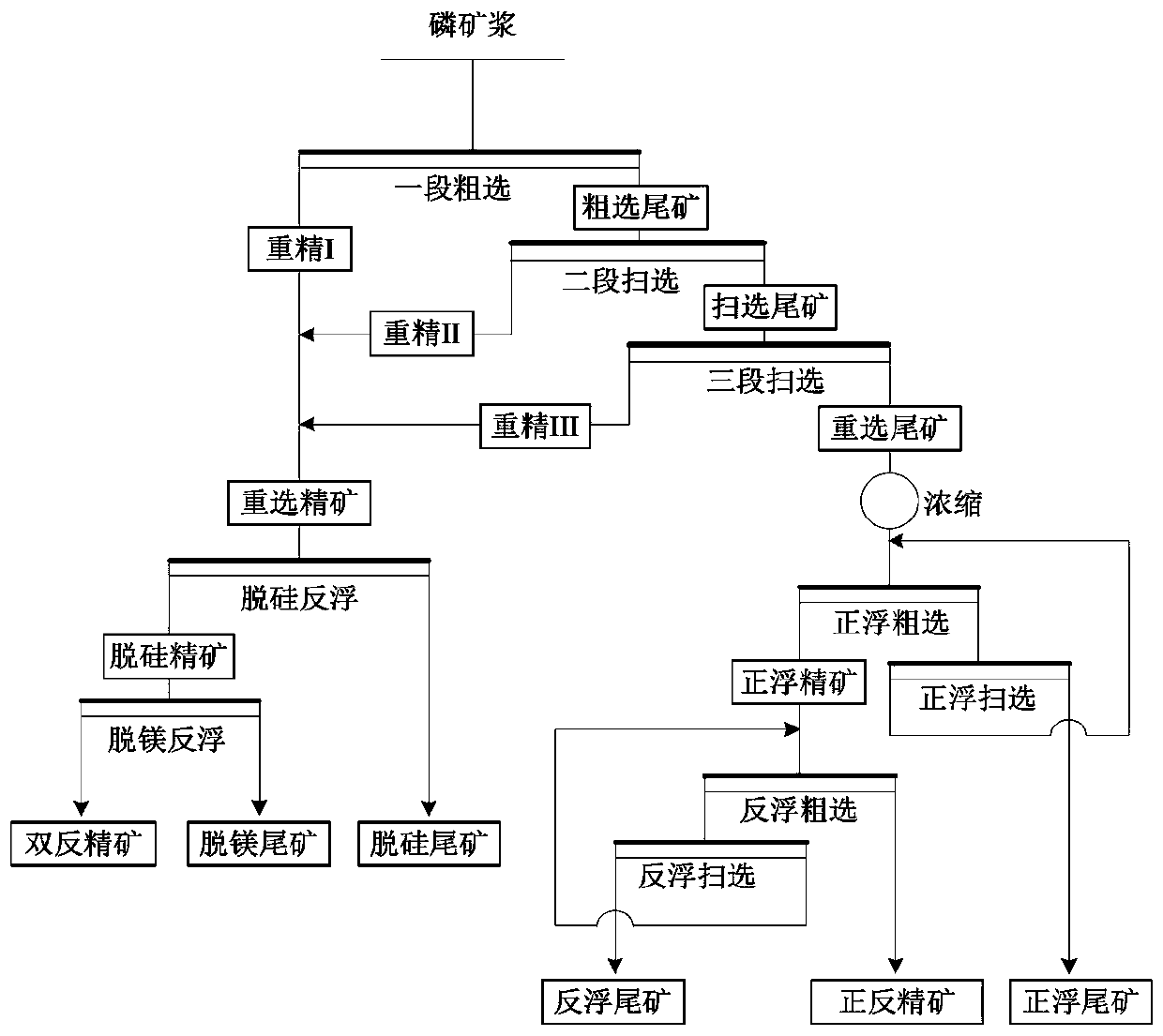

Gravity separation-flotation combined beneficiation process for phosphate ores

PendingCN110369120AReduce grinding costsReduce adverse effectsFlotationWet separationPhosphoriteReverse flotation

Owner:HUBEI XINGFA CHEM GRP CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap