Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Infrared thermal imaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

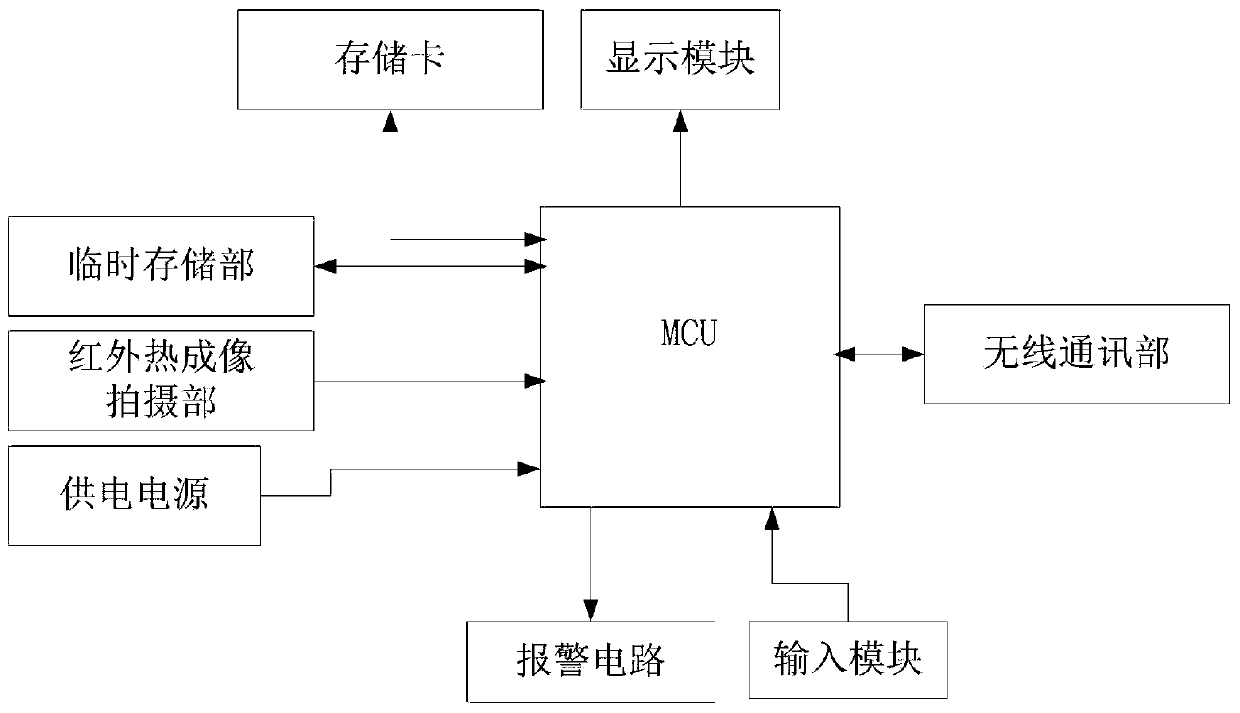

Handheld intelligent electrical line temperature patrol device, system and method

PendingCN111337141ALow costEasy to useProgramme controlRadiation pyrometryAlarm messageEmbedded system

Owner:沈阳美宝控制有限公司

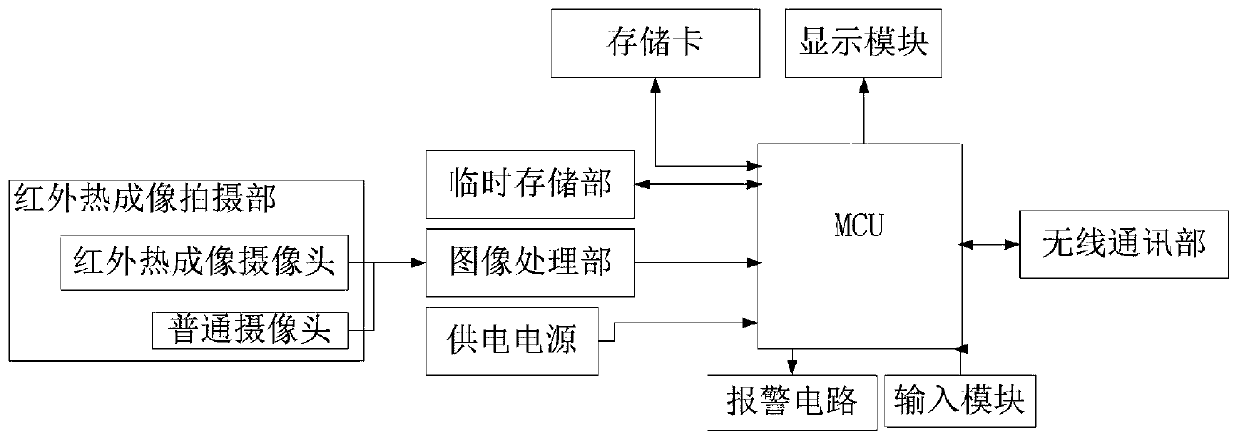

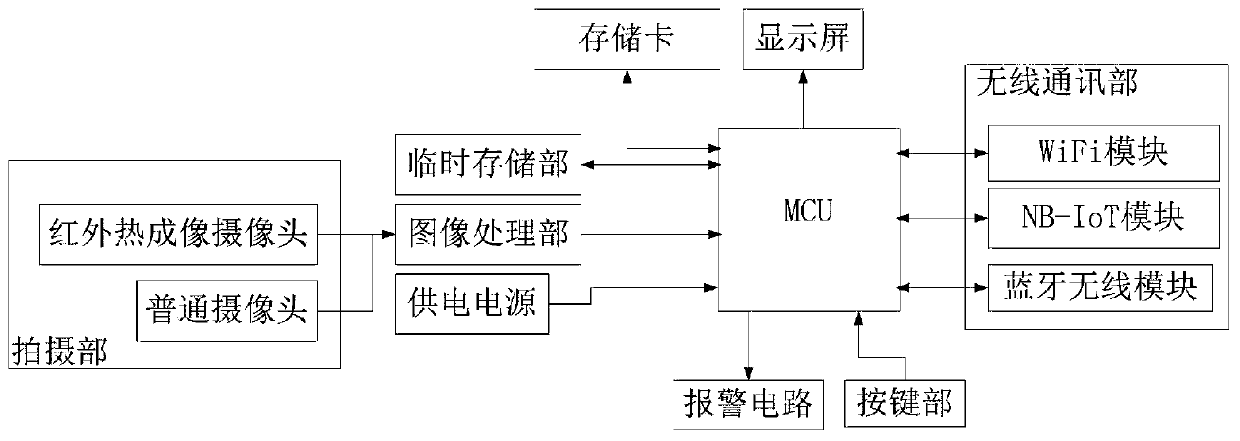

Novel temperature measurement equipment

PendingCN110411569ASolve the problem of multiple temperature measurement stepsSolve the cumbersomeRadiation pyrometryTime efficientPower user

Owner:江苏圣通电力新能源科技有限公司

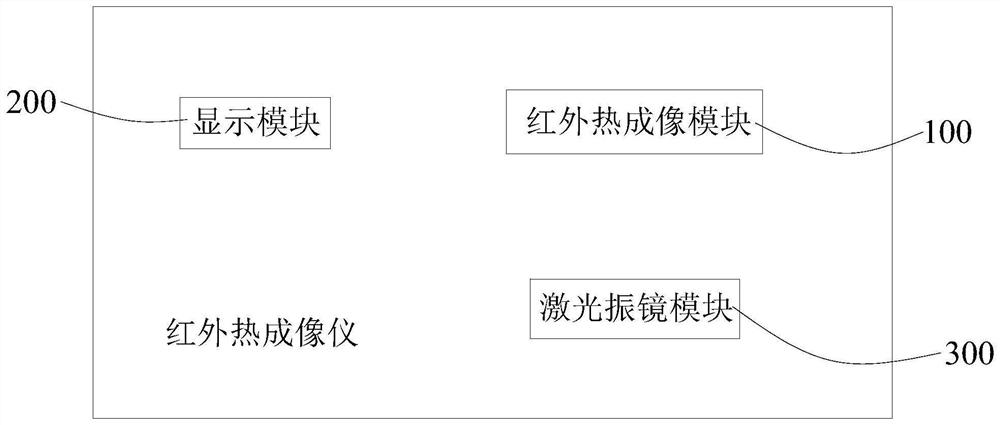

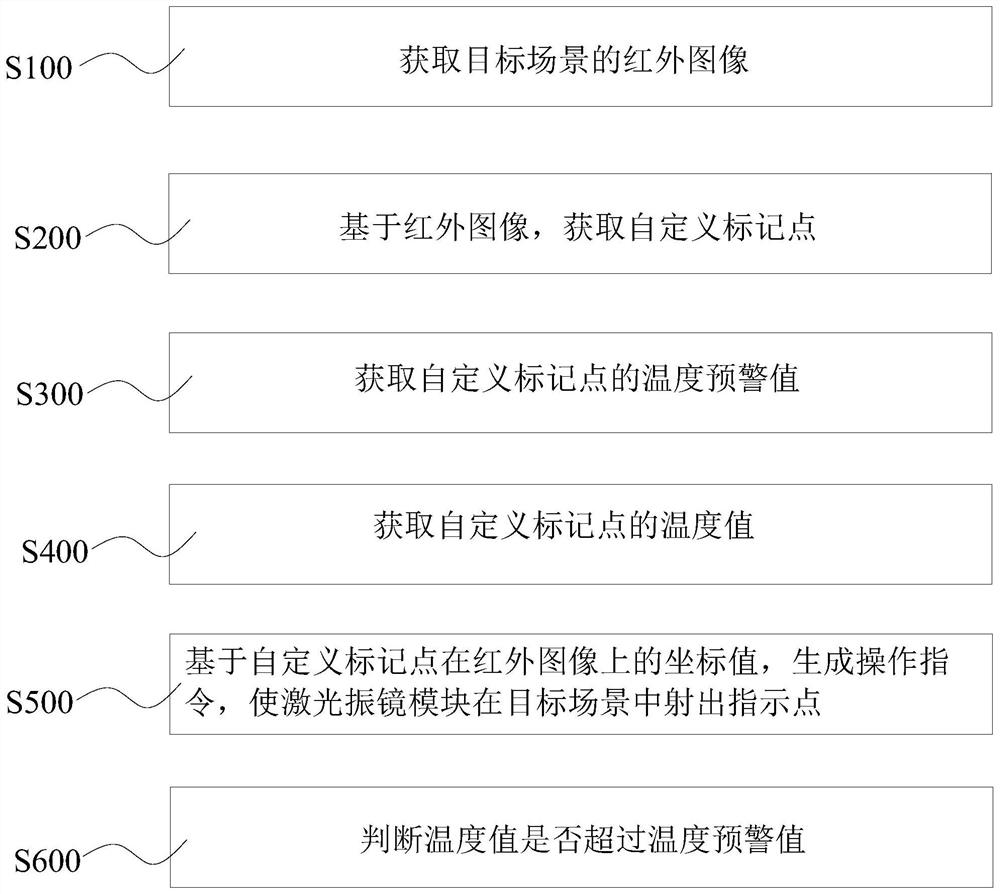

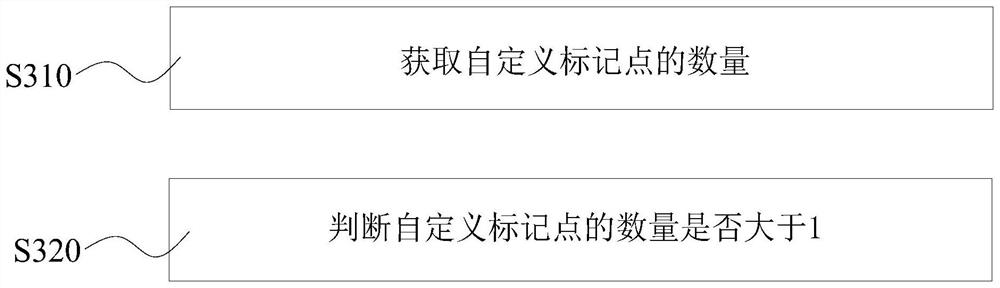

Dynamic marking method and device, computer equipment, medium and infrared thermal imager

PendingCN114323300ARealize patrol monitoringEasy to operateRadiation thermographyGalvanometerThermographic camera

Owner:UNI TREND TECH (CHINA) CO LTD

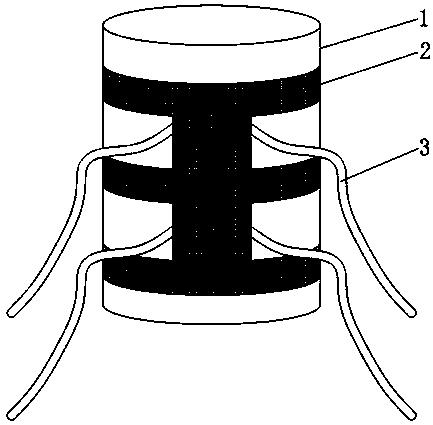

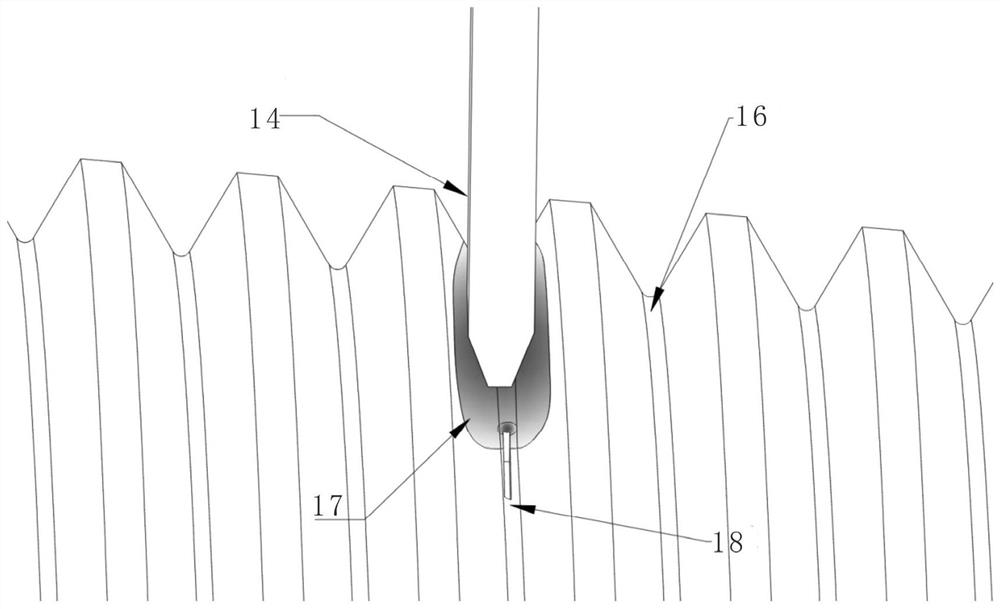

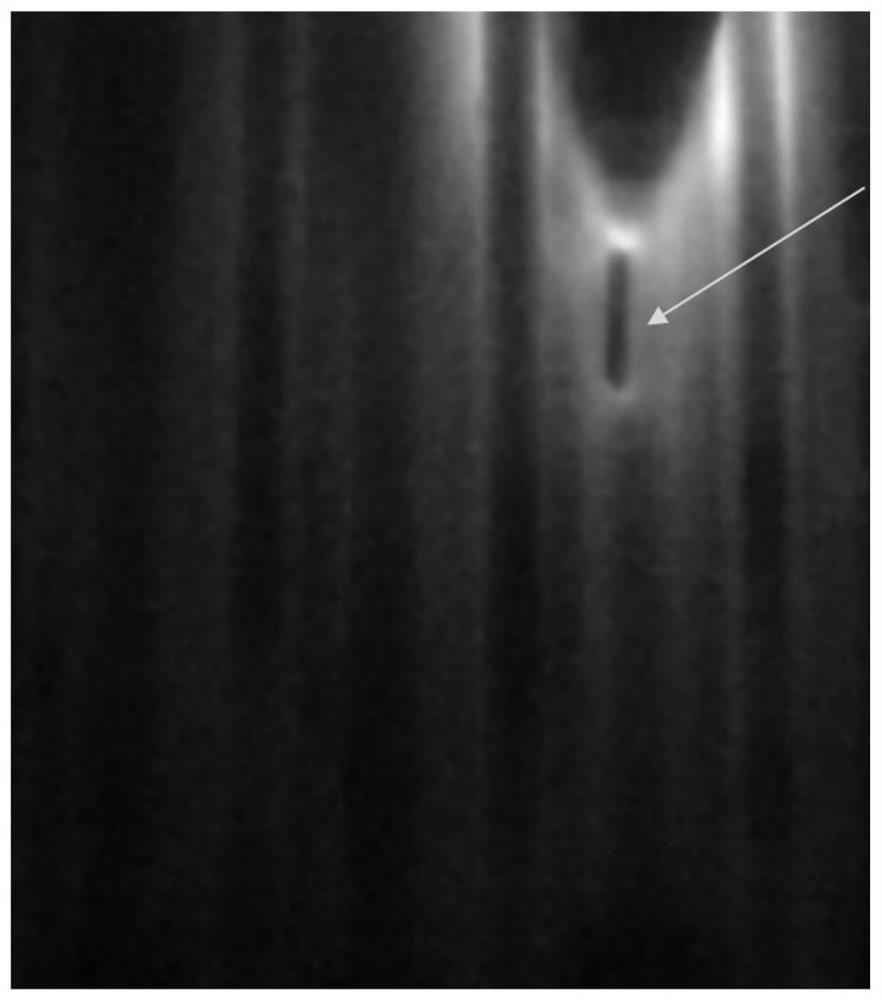

Drill rod thread detection device and method based on ferrite eddy current thermal imaging

PendingCN112114030ANo pollution in the processHigh speedElectric/magnetic position measurementsUsing electrical meansThermographic cameraManganese

Owner:成都鳌峰机电设备有限责任公司

Equipment detection system based on infrared imaging

ActiveCN113340941APrecise temperature controlPrecise air pressure controlRadiation pyrometryEngine testingTemperature controlEngineering

The invention provides an equipment detection system based on infrared imaging, which comprises an infrared thermal imaging module, a shaft controller, a gas transmission device, a temperature control device and a main control module, and is characterized in that the shaft controller is used for controlling rotation of an equipment rotor, the gas transmission device is used for providing gas for a working chamber of equipment, the temperature control device is used for controlling the temperature of gas entering a working chamber, the infrared thermal image module is used for generating an infrared thermal image of the gas in the working chamber and calculating the wear condition of equipment according to the change of the thermal image, and the main control module is used for intensively controlling the shaft controller, the gas conveying device and the temperature control device. According to the system, the wear condition of the equipment is detected through thermal images of two gases with different temperatures in the rotor working chamber, no damage is caused to an equipment body, and the system is non-destructive.

Owner:HUNAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap