Power adjustable microwave-heating drier

A microwave dryer and microwave heating technology, applied in heating to dry solid materials, drying solid materials, lighting and heating equipment, etc., can solve problems such as prolonged drying time, insufficient drying, and equipment cannot fully function, and achieve increased energy. utilization, improve the effect of reasonable matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

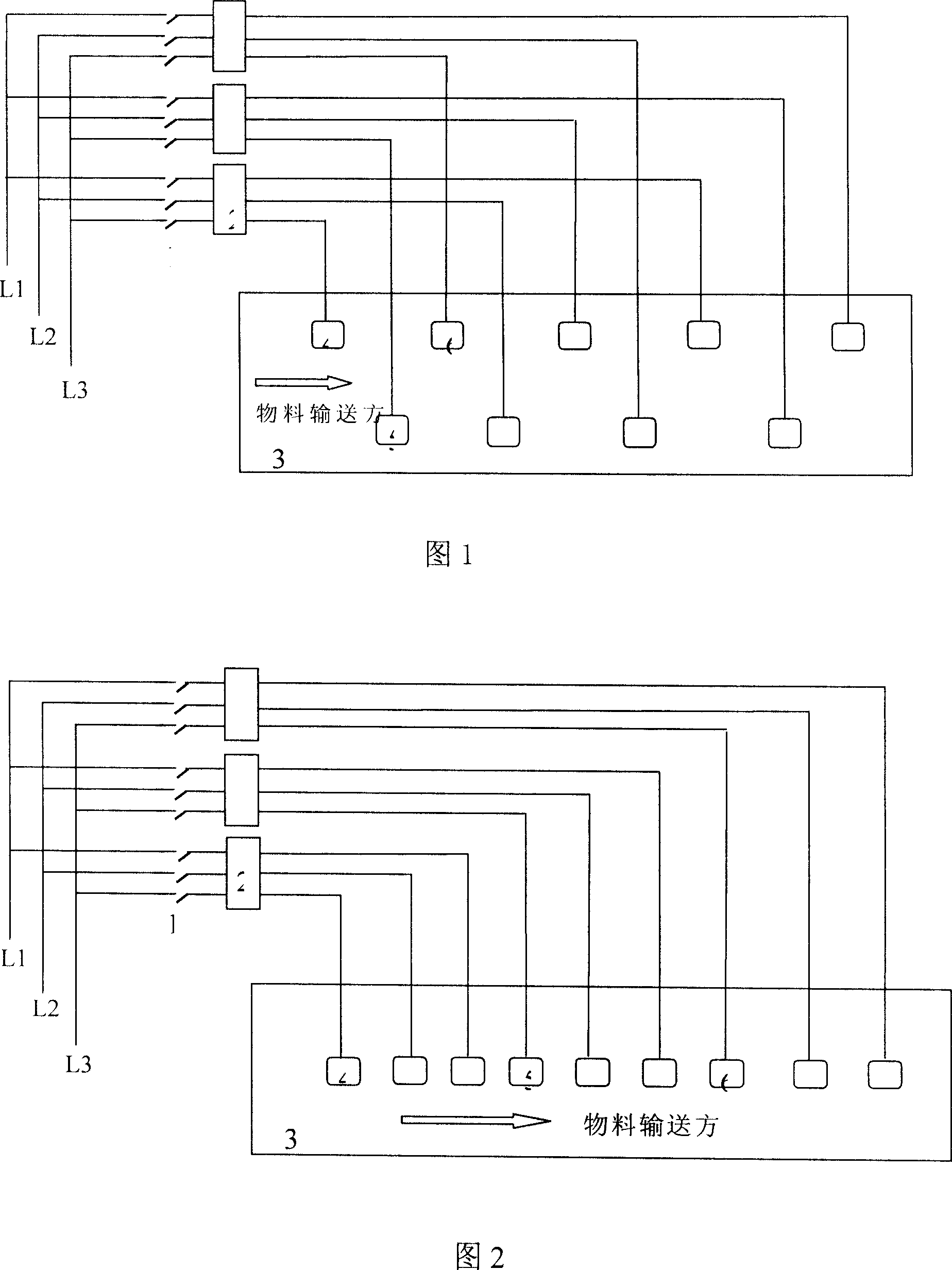

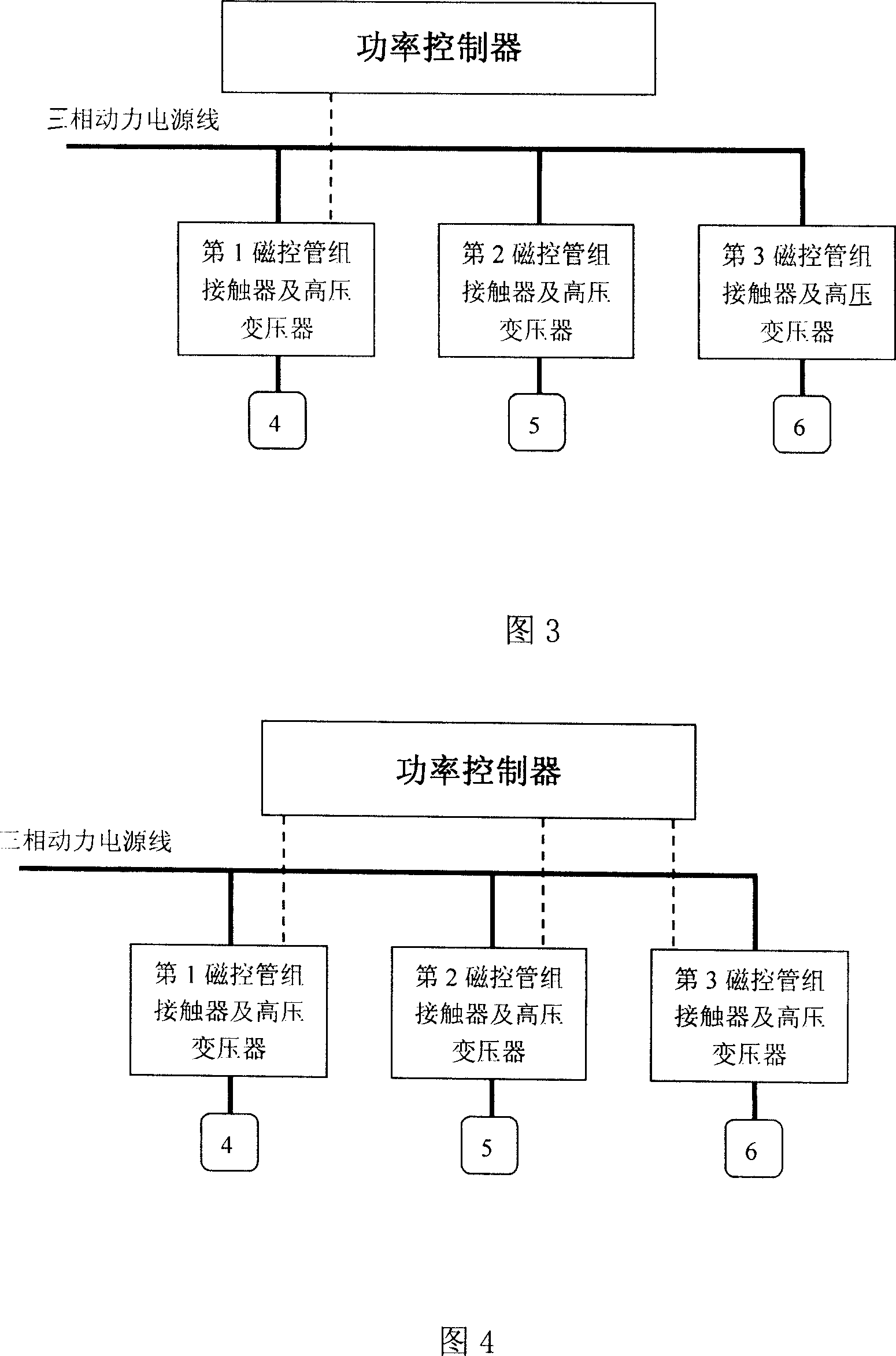

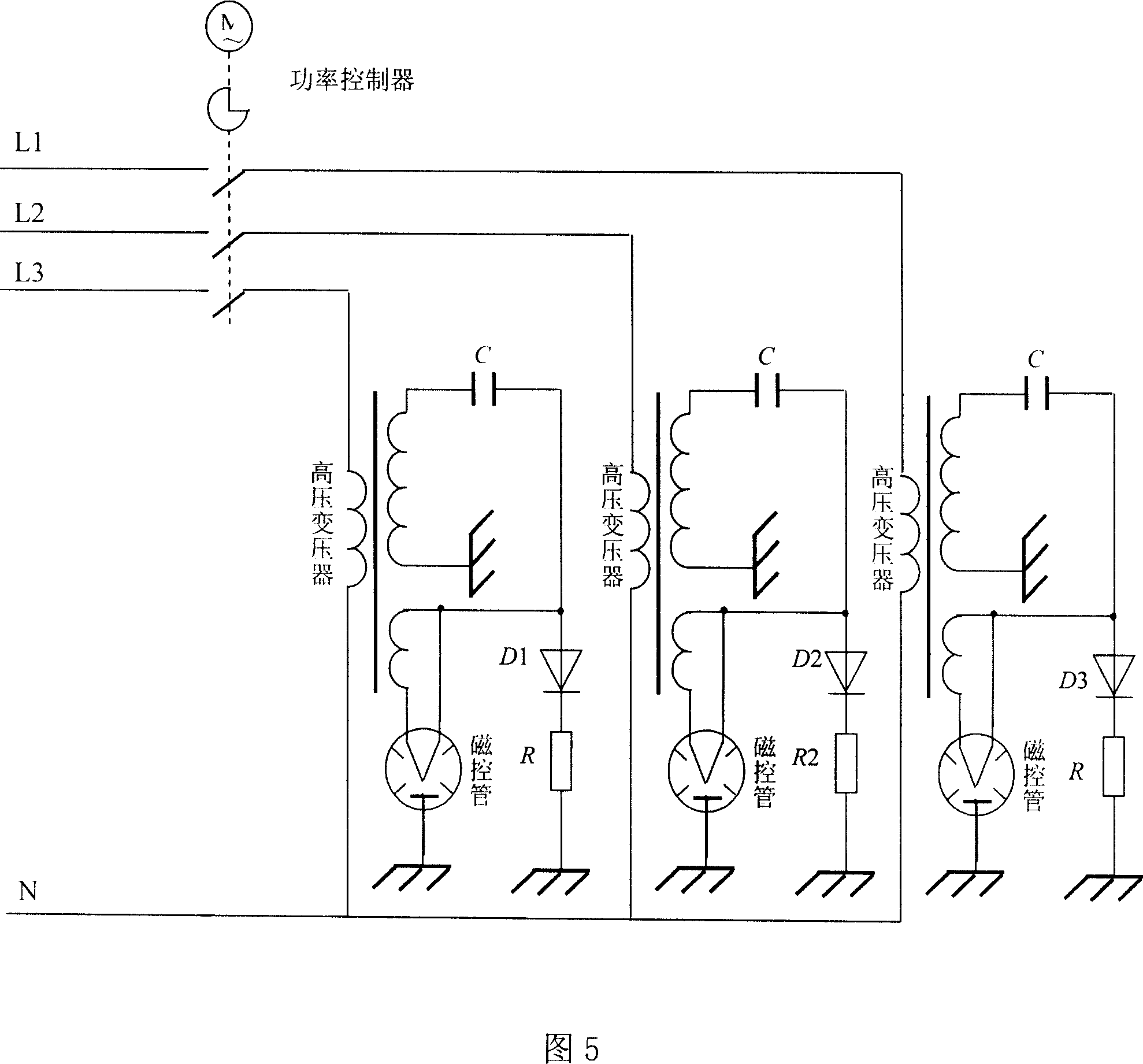

[0016] As shown in Figures 1, 3, and 5, the microwave heating dryer with adjustable power in this embodiment includes three microwave radiation circuit units installed in the dryer 3, and each microwave radiation circuit unit consists of a contactor 1, A high-voltage transformer 2 and a group of three magnetrons connected correspondingly to the three output terminals of the high-voltage transformer 2 constitute three input coils of the high-voltage transformer after the contactor of each microwave radiation circuit unit and three output coils of the contactor The terminals are correspondingly connected, the three output coils of the high-voltage transformer are correspondingly connected with three magnetrons, and the contactors of the three microwave radiation circuit units are respectively connected with three sets of magnetrons 4, 5, and 6. The magnetrons of each circuit unit are evenly distributed in the drying chamber, and the magnetrons of each circuit unit are staggered and

Embodiment 2

[0018] As shown in Figures 1, 4, and 5, the microwave heating dryer with adjustable power in this embodiment includes three microwave radiation circuit units installed in the dryer 3, and each microwave radiation circuit unit consists of a contactor 1, A high-voltage transformer 2 and a group of three magnetrons connected correspondingly to the three output ends of the high-voltage transformer 2 constitute three input coils of the high-voltage transformer and three output coils of the contactor behind the contactor of each microwave radiation circuit unit. The terminals are correspondingly connected, the three output coils of the high-voltage transformer are correspondingly connected with three magnetrons, and the contactors of the three microwave radiation circuit units are respectively connected with three groups of magnetrons 4, 5, and 6. The magnetrons in the drying chamber 3 are arranged in a horizontal single row, and a group of magnetrons of each microwave radiation circuit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap