Car engine timing system

A kind of technology of automobile engine, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of timing system assembly and maintenance difficulties, and achieve the effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

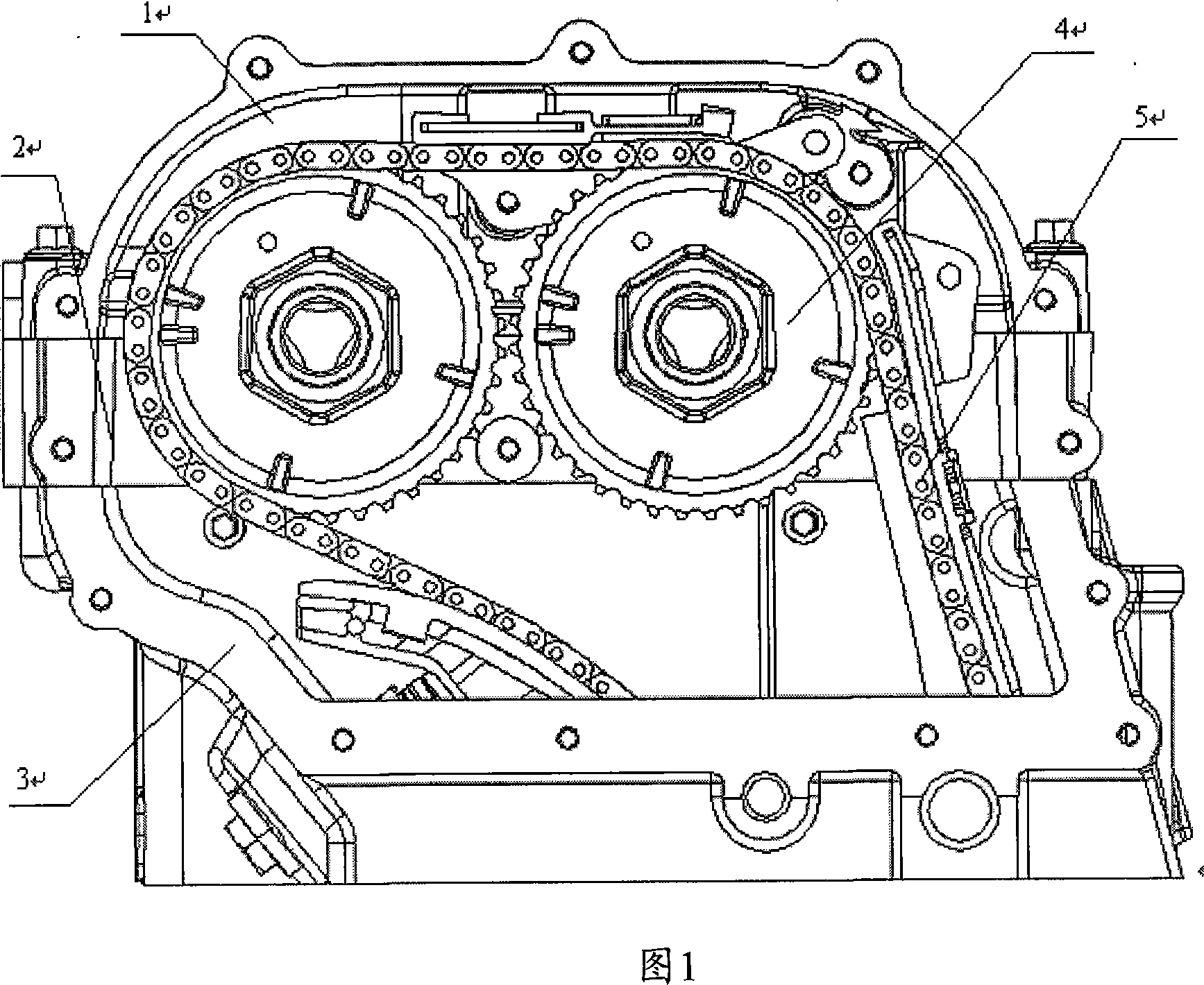

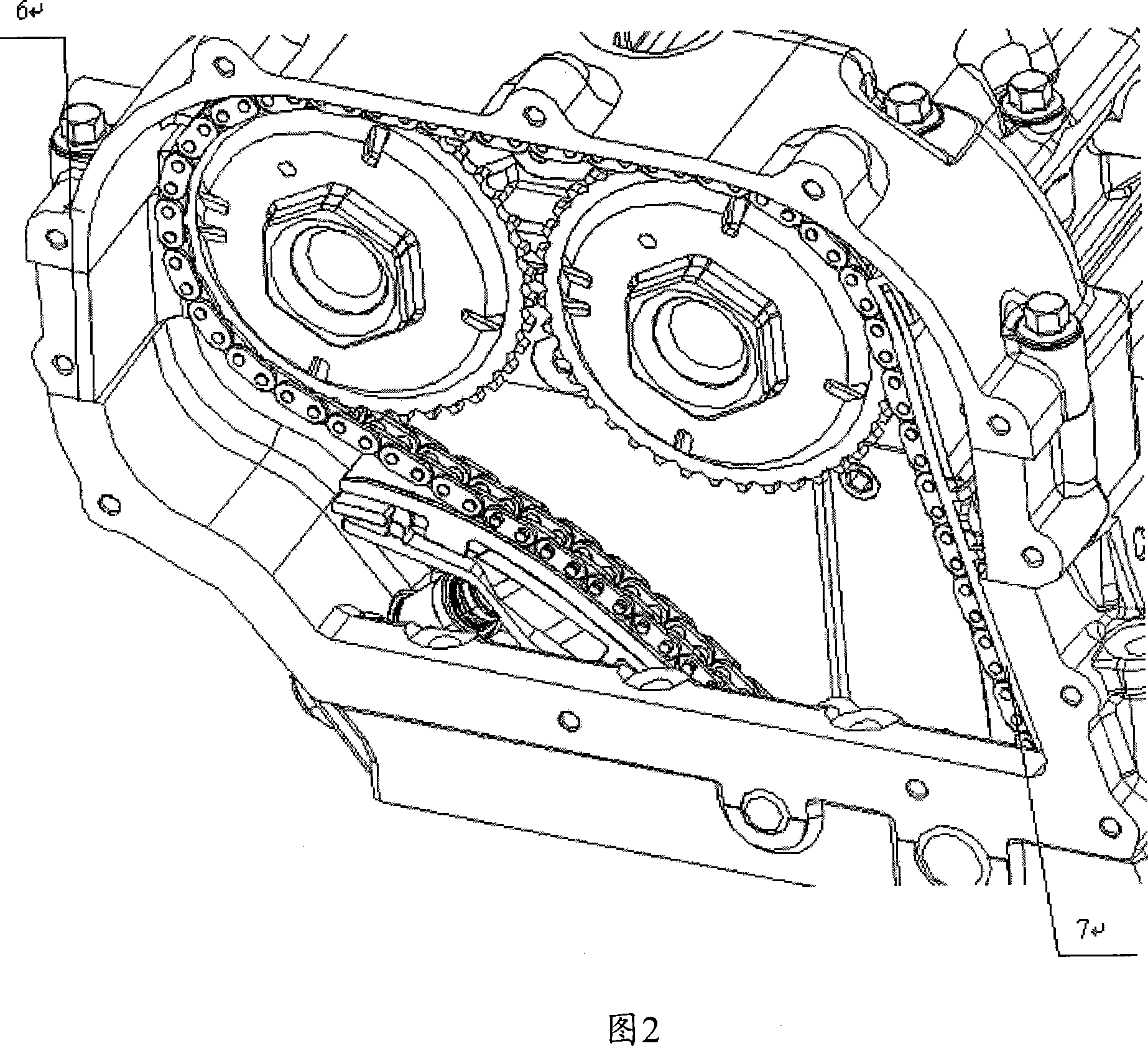

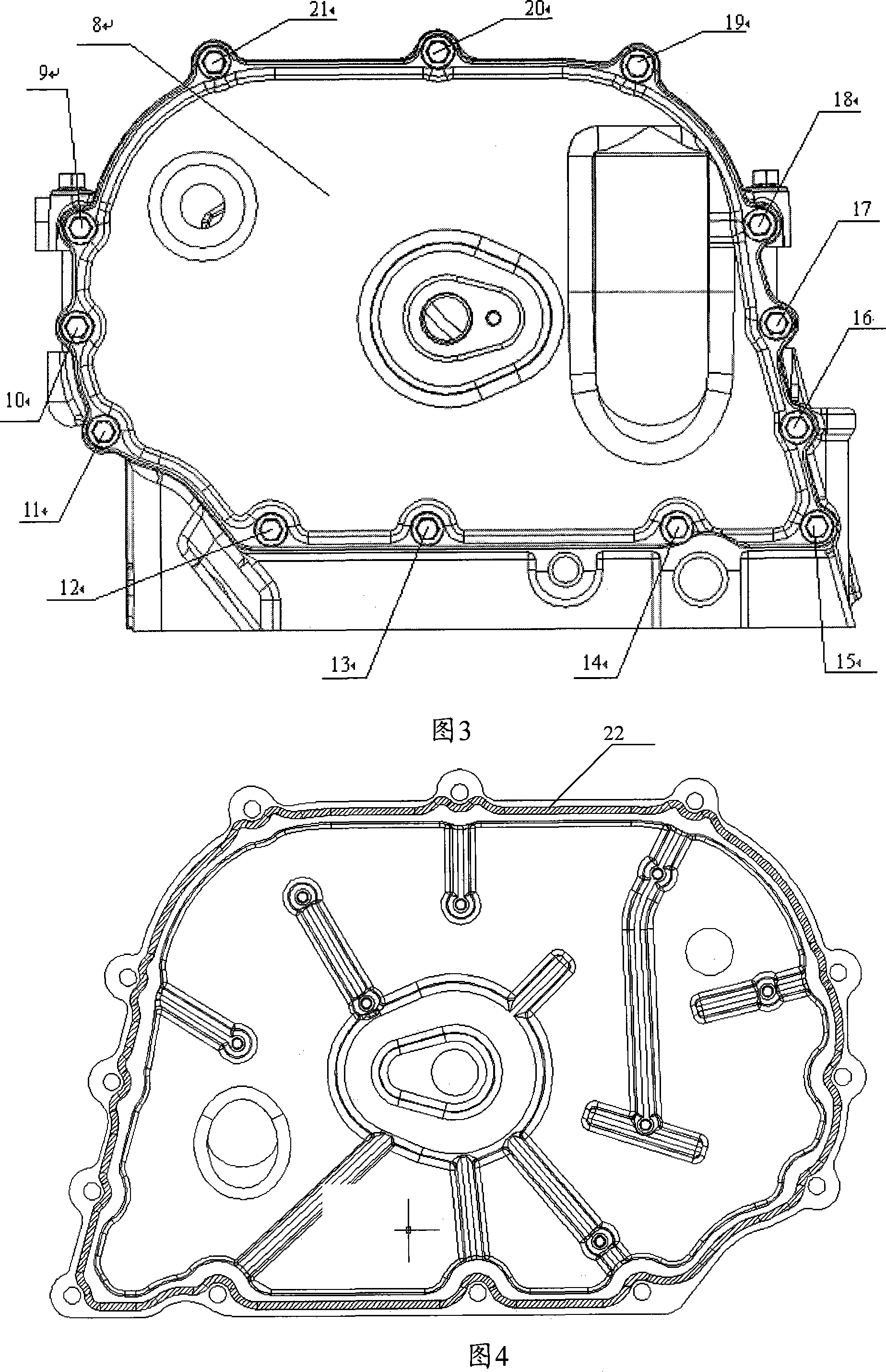

[0015] As shown in Figure 1-3, starting from the convenience of assembly and maintenance, plan enough space as the timing chamber, and then design it to the cylinder head 3, the lower camshaft frame 2 and the upper camshaft frame 1 (or valve chamber cover). Then install the cylinder head, lower camshaft frame and upper camshaft frame (or valve chamber cover) in sequence. A cover 8 is added to the timing chamber formed by the cylinder head 3 and the upper and lower camshaft frames 1 and 2, and the cover and the cylinder head, upper and lower camshaft frames are connected together by fastening bolts 9-21 and sealant to form a closed cavity. This not only ensures the convenience of installation and maintenance of the timing chain 5 and the sprocket 4, but also ensures that the lubricating oil necessary for the normal operation of the timing system will not leak out, and at the same time, external dust will not enter the timing chamber and affect the timing. The system works. It c

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap