Aging room used for the last assembling process of LCD screen

A liquid crystal display and aging room technology, applied in the field of aging room, can solve the problems of high energy consumption and low efficiency, and achieve the effects of reasonable layout, simple and convenient operation, and shortening the aging waiting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

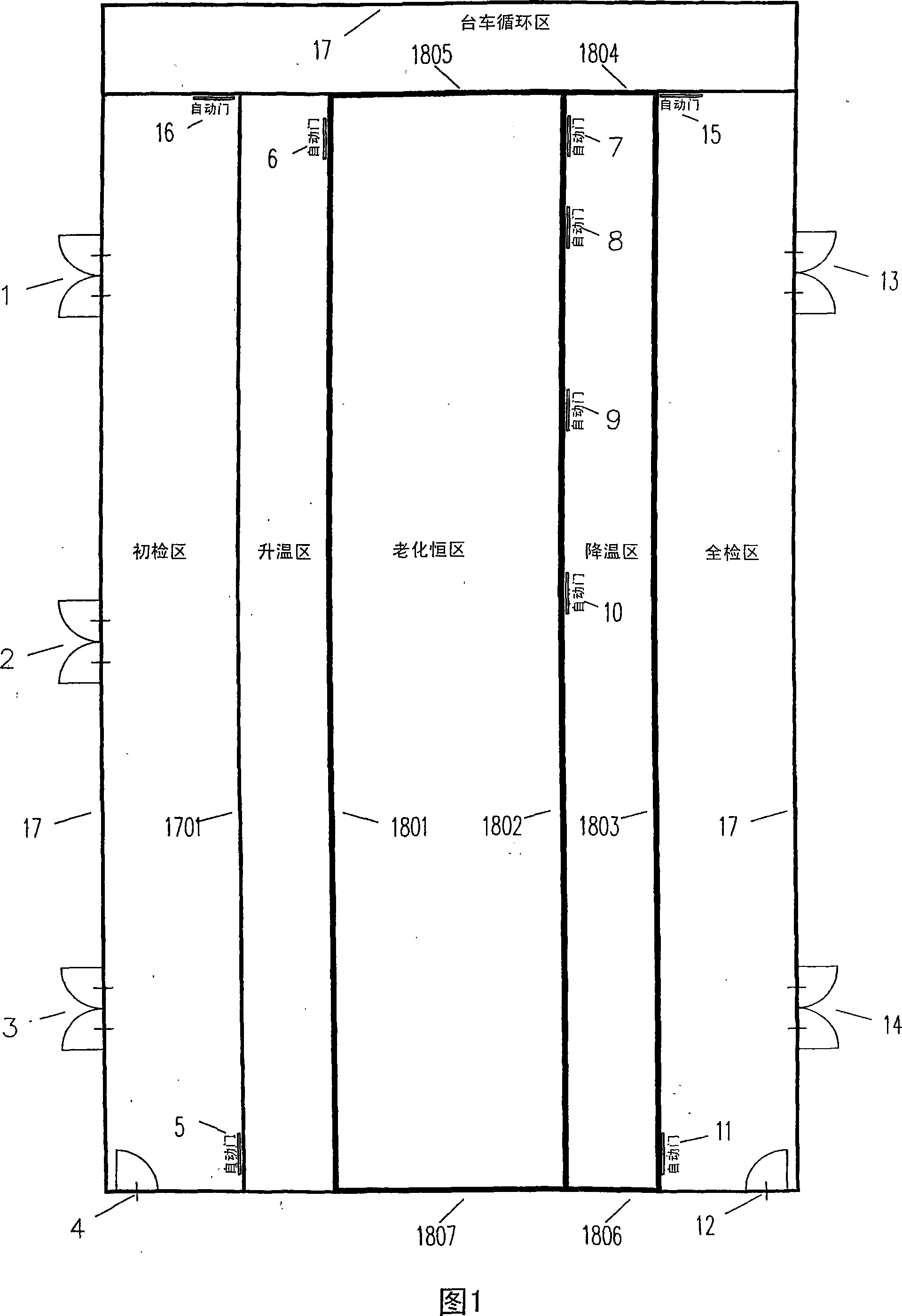

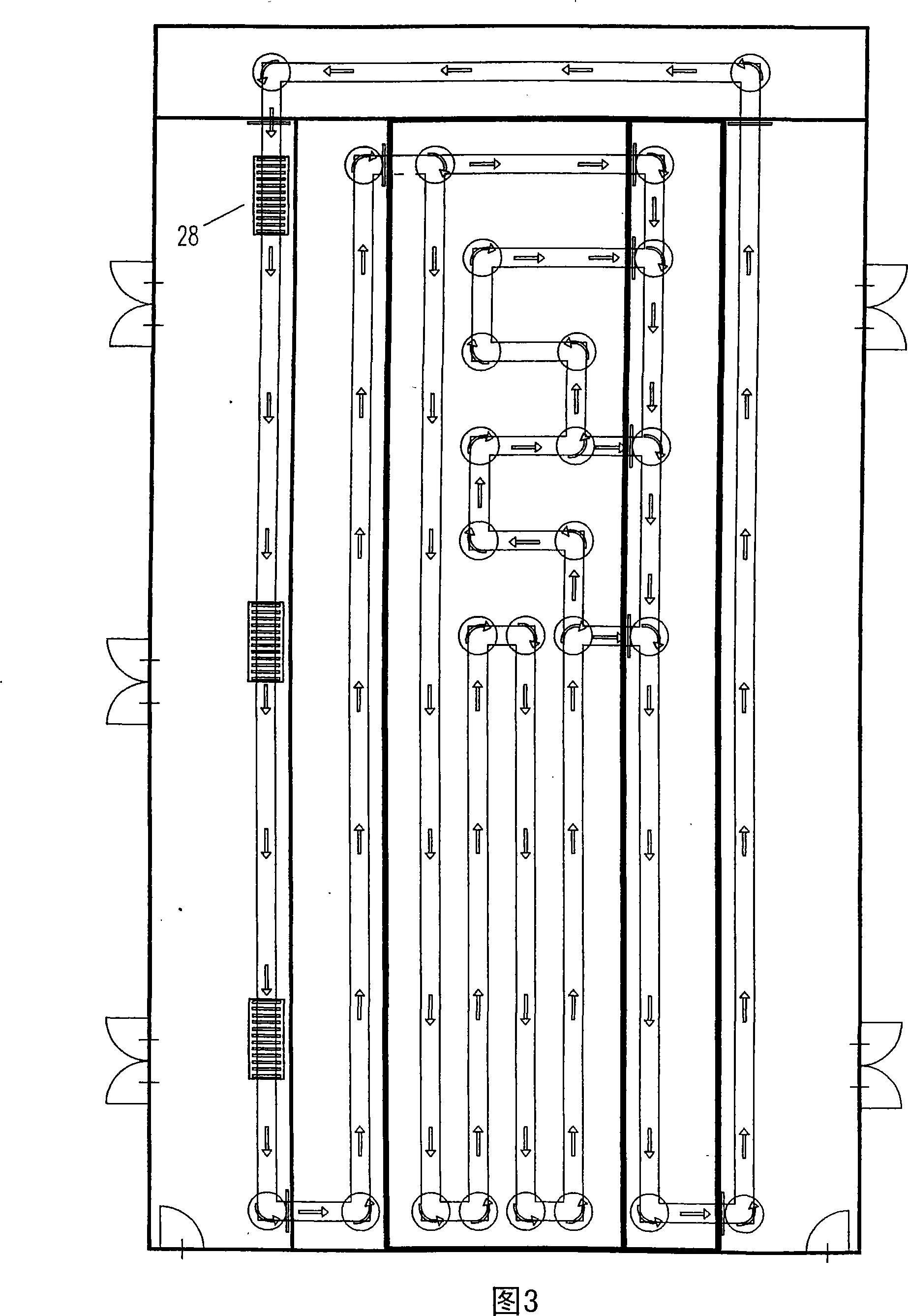

[0029] Below in conjunction with accompanying drawing, further illustrate the structure of aging room of the present invention.

[0030] Fig. 1, Fig. 2, Fig. 3 are the structural schematic diagrams of the aging chamber of the present invention.

[0031] As shown in FIG. 1, the aging chamber of the present invention is composed of an outer wall 17 and an outer cover. The aging room includes a preliminary inspection area, a heating area, an aging constant temperature area, a cooling area and a full inspection area.

[0032] There are display screen inlets of different sizes corresponding to different size display screens on the outer wall of the preliminary inspection area. In this embodiment, there are three screen inlets 1, 2, 3 of different sizes.

[0033] Located between the initial inspection area and the heating area, there is a next door 1701 with the entrance 5 of the heating area;

[0034] There is a first insulation wall 1801 with an inlet 6 of the constant temperature

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap