Lithium ion electrolytic solution preventing over charge and lithium ion battery made therefrom

An electrolyte preparation, lithium ion technology, applied in the field of lithium ion batteries, can solve the problems of affecting cycle efficiency, performance degradation of lithium ion batteries, affecting battery charge and discharge capacity, etc., to improve cycle efficiency, low cost, and improve overcharge resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

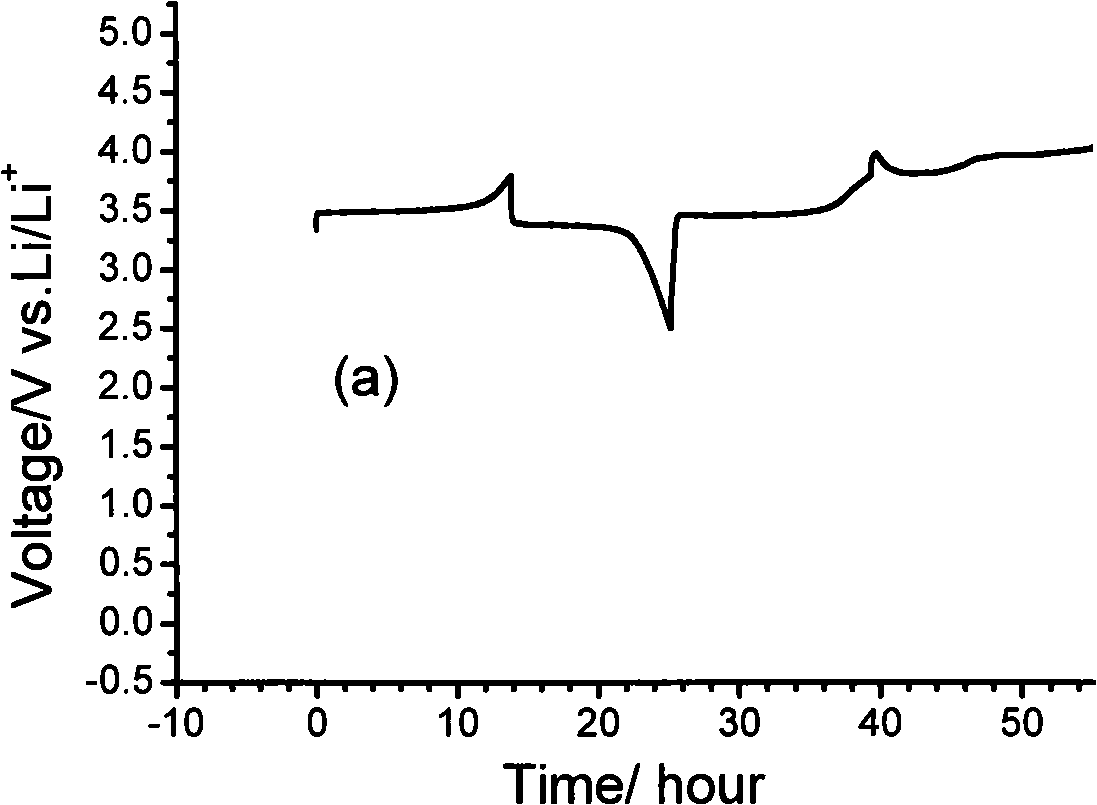

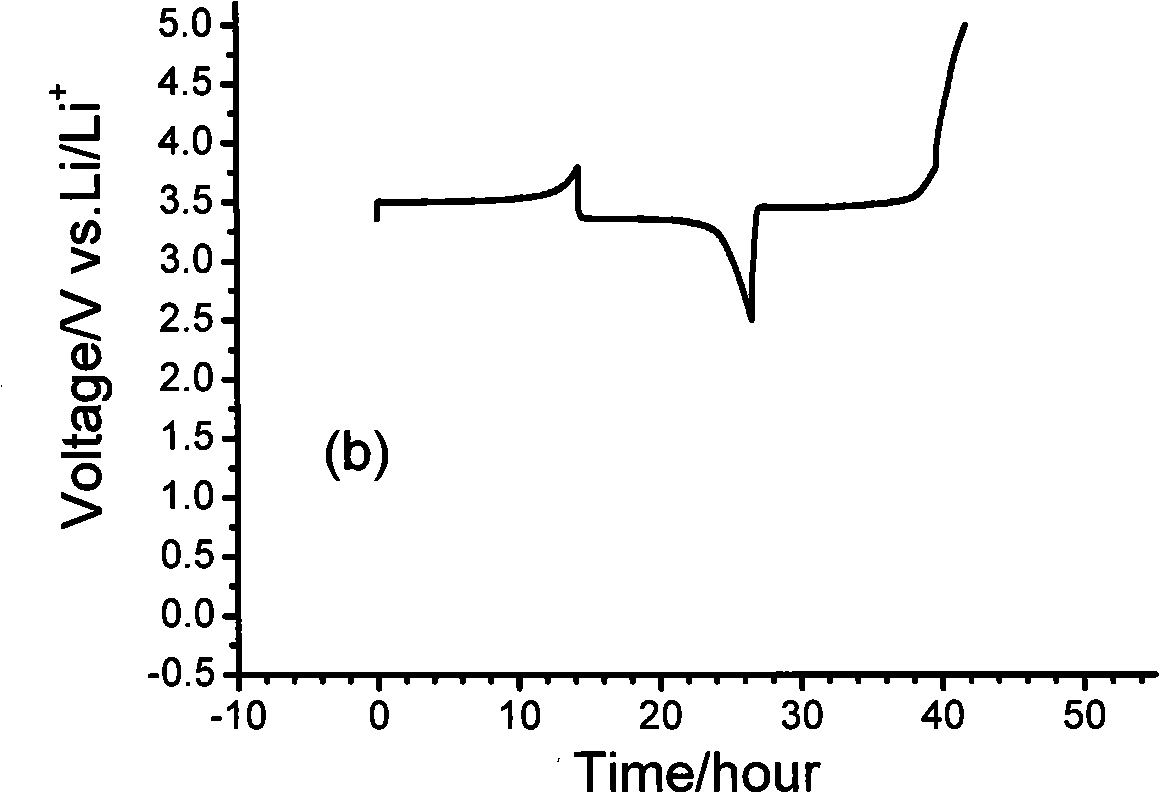

Embodiment 1

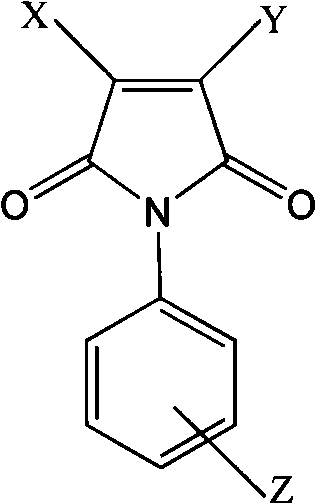

[0014] Mix ethylene carbonate, dimethyl carbonate, and methyl ethyl carbonate in a ratio of 1:1:1, add a certain amount of lithium hexafluorophosphate to it to prepare a 1mol / L electrolyte, and then add the The additive N-phenylimide is dissolved to prepare the electrolyte solution of the present invention. Based on the weight of the electrolyte, the composition of the additive is:

[0015] N-phenylimide 1wt.%.

[0016] Preparation of positive electrode: a certain amount of LiCoO 2 and acetylene black are evenly dispersed in a solvent made of polyvinylidene fluoride (PVDF) dissolved in N-methyl-2-pyrrolidone (NMP) to obtain a uniform slurry, coated with aluminum foil and dried in a vacuum at 120°C After 12 hours, the positive electrode sheet was obtained after calendering.

[0017] Preparation of the negative electrode: A certain amount of carbon mesophase microspheres (CMS) and acetylene black are uniformly dispersed in a solvent in which polyvinylidene fluoride (PVDF) is d

Embodiment 2

[0020] Mix ethylene carbonate, dimethyl carbonate, and methyl ethyl carbonate in a ratio of 1:1:1, add a certain amount of lithium hexafluorophosphate to it to prepare a 1mol / L electrolyte, and then add additives to it , making it dissolve to prepare the electrolyte solution of the present invention. Based on the weight of the electrolyte, the composition of the additive is:

[0021] N-phenylimide 3wt.%.

[0022] According to the same method as in Example 1, a lithium-ion secondary battery was prepared using the electrolyte solution obtained in this example.

Embodiment 3

[0024] Mix ethylene carbonate, dimethyl carbonate, and methyl ethyl carbonate in a ratio of 1:1:1, add a certain amount of lithium hexafluorophosphate to it to prepare a 1mol / L electrolyte, and then add additives to it , making it dissolve to prepare the electrolyte solution of the present invention. Based on the weight of the electrolyte, the composition of the additive is:

[0025] N-phenylimide 5wt.%.

[0026] According to the same method as in Example 1, a lithium-ion secondary battery was prepared using the electrolyte solution obtained in this example.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap