Production technique of LED luminous laminated glass

A manufacturing process and luminous interlayer technology, applied in semiconductor/solid-state device manufacturing, electrical components, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In this implementation case, laser engraving is used to carve the LED conductive circuit on the conductive coated glass plate, and tinned copper strips are used as power leads, and the LED and tinned copper strips are bonded to the conductive coating with special conductive adhesive. On the glass plate, the drying temperature is 150°C. The LED conductive coated glass plate after drying is shown in the attached figure. 15 LEDs are designed and arranged on the conductive glass plate, which are divided into 5 groups vertically, and each group consists of three LEDs connected in series.

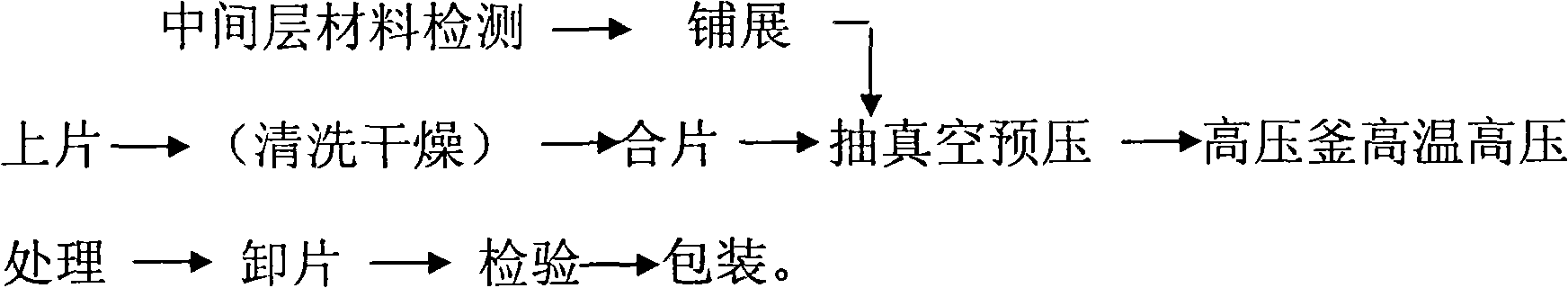

[0038] In this implementation case, the processing process of luminescent laminated glass is as follows:

[0039]

[0040] In this implementation case, the selected middle layer is PVB material with a total thickness of 1.52mm. The laminated film room has a cleanliness of more than 100,000 grades, an ambient relative humidity of 25%, and an ambient temperature of 23°C.

[0041] In this

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap